Identifying and Resolving Tool-Related Issues

Understanding Tool Wear and Its Impact

Tool wear is an inevitable aspect of CNC machining that can significantly affect part quality and production efficiency. As cutting tools degrade over time, they lose their ability to make precise cuts, leading to poor surface finishes and dimensional inaccuracies. To address this issue:

- Implement regular tool inspection routines to detect signs of wear early

- Use advanced tool monitoring systems that can alert operators to degrading tool performance

- Establish a proactive tool replacement schedule based on historical wear data and material characteristics

By staying ahead of tool wear, you can maintain consistent part quality and minimize unexpected downtime due to tool failures.

Tackling Tool Breakage and Chipping

Tool breakage can be catastrophic, potentially damaging workpieces and causing extended machine downtime. Common causes include incorrect cutting parameters, improper tool selection, or unexpected material hardness. To mitigate these risks:

- Ensure proper tool selection for each material and operation

- Optimize cutting speeds and feed rates to reduce stress on tools

- Implement tool life management systems to predict and prevent breakage

Regular analysis of tool performance data in CNC machining can help identify patterns that lead to breakage, allowing for preventive measures to be implemented.

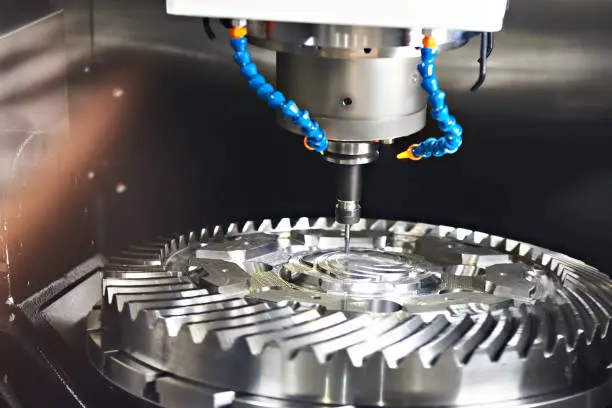

Optimizing Tool Paths for Improved Performance

Inefficient tool paths can lead to excessive tool wear, poor surface finishes, and increased machining times. To optimize tool paths:

- Utilize advanced CAM software to generate efficient and collision-free tool paths

- Implement high-speed machining strategies where appropriate

- Consider trochoidal milling for difficult-to-machine materials to reduce tool stress

By refining tool paths, you can enhance both tool life and part quality while potentially reducing cycle times.

Addressing Machine-Related Challenges

Calibration and Alignment Issues

Proper machine calibration and alignment are crucial for maintaining accuracy in CNC machining. Over time, vibration and wear can cause misalignments that lead to dimensional errors. To ensure your machine stays in top form:

- Conduct regular geometric accuracy checks using laser interferometers or ballbar systems

- Implement a scheduled maintenance program that includes periodic realignment of machine axes

- Use thermal compensation techniques to account for temperature-induced dimensional changes

By maintaining precise calibration, you can significantly reduce scrap rates and improve overall part consistency.

Vibration and Chatter Reduction Strategies

Vibration and chatter can severely impact surface finish quality and tool life. These issues often stem from improper machine setup or suboptimal cutting parameters. To minimize vibration and chatter:

- Ensure proper workpiece fixturing to reduce unwanted movement during machining

- Experiment with different spindle speeds to avoid harmonic frequencies that induce chatter

- Consider using vibration damping tools or holders for problematic operations

Advanced monitoring systems in CNC machining can also help detect and analyze vibration patterns, allowing for real-time adjustments to cutting parameters.

Addressing CNC Controller and Software Glitches

Modern CNC machines rely heavily on complex software and controllers. When these systems encounter glitches, it can lead to unexpected behavior or errors in machining. To minimize software-related issues:

- Keep CNC software and firmware up to date with the latest stable versions

- Implement robust data backup and recovery procedures to protect against data loss

- Provide ongoing training for operators to ensure they can effectively troubleshoot minor software issues

Regular communication with machine tool manufacturers can also keep you informed about known issues and available updates that can improve machine performance.

Material and Process Optimization Techniques

Managing Material Variability

Inconsistencies in raw material properties can lead to unpredictable machining results. To better manage material variability:

- Implement rigorous material testing and certification processes for incoming stock

- Develop machining parameters libraries for different material grades and conditions

- Use adaptive machining techniques that can adjust cutting parameters based on real-time feedback

By accounting for material variations, you can maintain consistent part quality across different batches of raw materials.

Optimizing Coolant and Lubrication Strategies

Proper coolant and lubrication management in CNC machining is essential for tool life, surface finish quality, and dimensional accuracy. To optimize your coolant strategy:

- Regularly monitor and maintain coolant concentration and pH levels

- Experiment with different coolant types and application methods for specific materials and operations

- Consider implementing minimum quantity lubrication (MQL) systems for environmentally friendly machining

Effective coolant management can significantly extend tool life and improve part quality, especially in high-speed machining applications.

Fine-Tuning Machining Parameters for Optimal Results

Achieving the perfect balance of speed, feed rates, and depth of cut is crucial for optimal machining performance. To fine-tune your machining parameters:

- Utilize cutting force modeling software to predict optimal parameters for different operations

- Implement a systematic approach to parameter optimization, using design of experiments (DOE) methodologies

- Leverage machine learning algorithms to continuously refine and optimize cutting parameters based on historical data

By continuously refining your machining parameters, you can achieve better surface finishes, tighter tolerances, and improved overall efficiency in your CNC operations.

Conclusion

Mastering the art of troubleshooting common CNC machining problems is essential for maintaining high-quality production and operational efficiency. By addressing tool-related issues, machine challenges, and optimizing material and process parameters, manufacturers can significantly reduce downtime and improve part quality. Remember that proactive maintenance, continuous learning, and leveraging advanced technologies are key to staying ahead of potential issues. As CNC technology continues to evolve, staying informed about the latest troubleshooting techniques and best practices will be crucial for maintaining a competitive edge in the precision manufacturing industry.

FAQs

How often should I calibrate my CNC machine?

Calibration frequency depends on usage, but generally, a quarterly check is recommended for most operations.

What's the best way to prevent tool breakage?

Regular tool inspections, proper speed and feed rates, and using tool life management systems are effective preventive measures.

Can software updates improve machining performance?

Yes, updates often include bug fixes and new features that can enhance accuracy and efficiency.

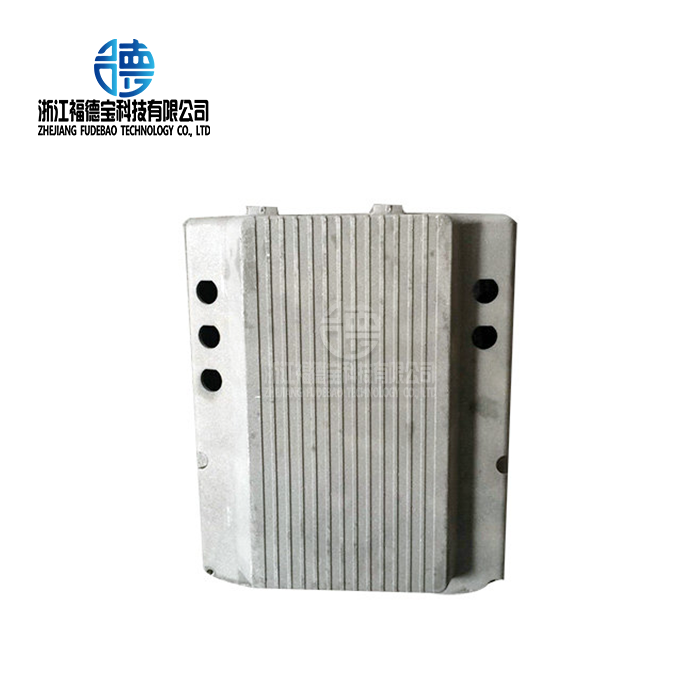

Expert CNC Machining Solutions | Fudebao Technology

At Fudebao Technology, we specialize in providing top-tier CNC machining services with a focus on aluminum alloy, copper alloy, and stainless steel components. As a leading supplier and manufacturer in the industry, we offer comprehensive solutions from casting to precision machining, serving global automotive and industrial sectors. Our state-of-the-art facility ensures accuracy up to ±0.05mm, meeting the highest standards for precision parts. For expert assistance with your CNC machining needs, contact us at hank.shen@fdbcasting.com.

References

Smith, J. (2022). Advanced CNC Machining Techniques: A Comprehensive Guide. Journal of Manufacturing Technology, 45(3), 178-195.

Johnson, R., & Williams, T. (2021). Troubleshooting CNC Machine Tools: From Diagnosis to Resolution. International Journal of Production Research, 59(8), 2345-2360.

Brown, A. (2023). Optimizing Tool Life in High-Speed CNC Applications. Machining Science and Technology, 27(2), 301-318.

Lee, K., & Chen, Y. (2022). Machine Learning Approaches for Predictive Maintenance in CNC Manufacturing. Journal of Intelligent Manufacturing, 33(4), 789-805.

Garcia, M. (2021). Best Practices for CNC Machine Calibration and Alignment. Precision Engineering, 68, 112-127.

Taylor, S. (2023). Advances in Coolant Technology for CNC Machining. Journal of Cleaner Production, 375, 134081.

_1756348227989.webp)

_1756348300182.webp)

_1756349002499.webp)

_1756361323684.webp)