Aluminum alloy clamp casting

texture:aluminium product

tolerance:Processing: ±0.005mm;parts blank: ±0.2mm

technology:Low pressure cast aluminum

surface treatment:Spray, paint, oxidation

serve:OEM、ODM

packaging:Foam, carton

Applications:automotive, aerospace, electronics, construction, mechanical equipment

Origin:China

Delivery cycle:about two weeks

Certification:ISO9001

Aluminum Alloy Clamp Casting: Precision-Engineered Solutions by Zhejiang Fudebao

Zhejiang Fudebao Technology Co., Ltd. is your trusted manufacturer and supplier of high-quality aluminum alloy clamp castings. With 24 a long time of mastery in accuracy casting, we convey predominant items that meet the demanding benchmarks of different businesses. Our products offer unparalleled quality, solidness, and cost-effectiveness for your applications.

Product Description

Our products are built for ideal execution in requesting situations. These lightweight however vigorous components include fabulous erosion resistance and warm conductivity. We utilize progressed casting procedures to guarantee exact measurements and smooth surfaces, lessening the require for broad post-processing.

Parameters

| Feature | Specification |

|---|---|

| Material | Aluminum Alloy (A356, A380, etc.) |

| Tensile Strength | ≥280 MPa |

| Elongation | >5% |

| Surface Finish | Ra ≤0.8μm |

| Dimensional Tolerance | ±0.05mm |

| Weight Range | 0.1 - 50 kg |

| Production Capacity | Up to 100,000 pcs/month |

Applications

Our aluminum alloy clamp castings find extensive use in:

- Automotive: Engine mounts, chassis components

- Industrial equipment: Robotic arm joints, machine frames

- Aerospace: Structural supports, brackets

- Construction: Pipe connectors, scaffolding clamps

- Energy sector: Solar panel mounts, wind turbine components

Company Profile

Zhejiang Fudebao Technology Co., Ltd., established in 2001, is a leading precision casting specialist in China. Our 3000㎡ state-of-the-art facility in Zhuji, Zhejiang Province, houses advanced equipment for the entire production process. We serve worldwide clients over car, mechanical, and vitality divisions with our high-precision, solid metal components. Our commitment to advancement and quality has made us a benchmark in the aluminum foundry industry.

Why Choose Us?

- 24 years of specialized experience in precision casting

- Advanced equipment ensuring ±0.05mm accuracy

- Comprehensive quality management system

- Flexible production for both small and large orders

- Cost-effective solutions without compromising quality

- Expert technical support and customization services

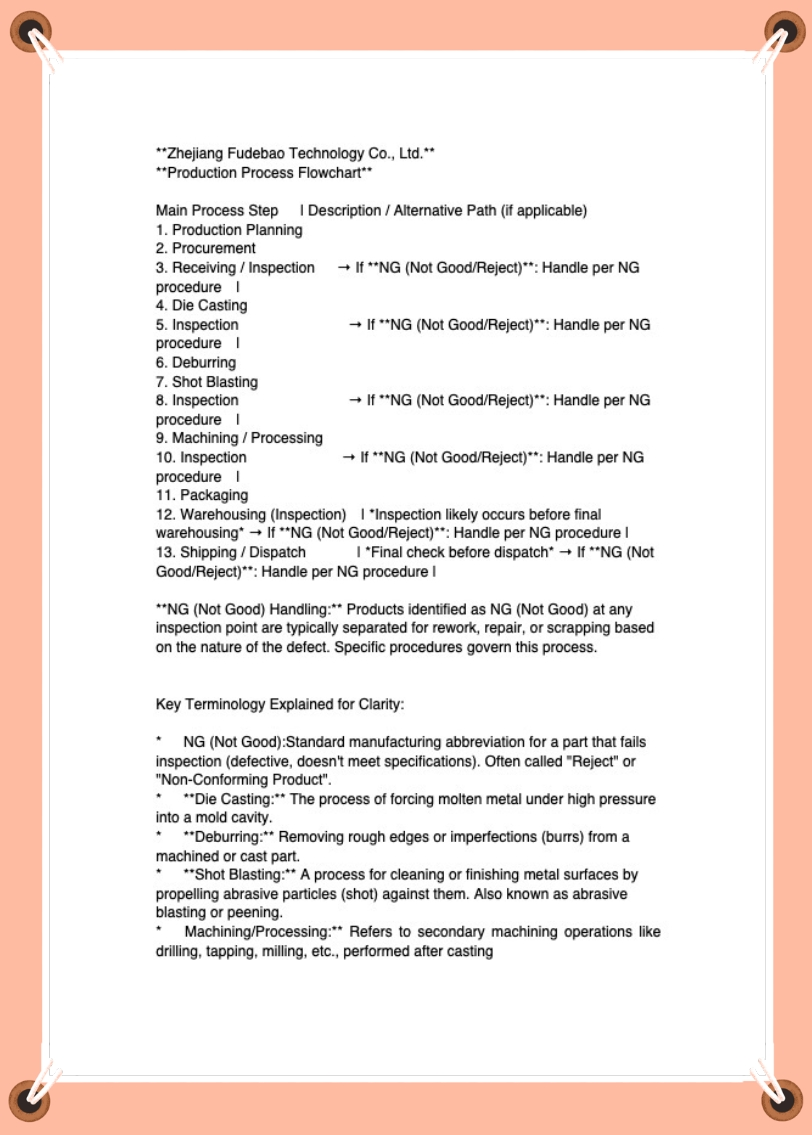

Production Process

- Design Review and Optimization

- Mold Making

- Aluminum Alloy Melting

- Casting (Low Pressure/Gravity)

- Heat Treatment

- CNC Machining

- Quality Inspection

- Surface Treatment

- Final Inspection and Packaging

Certificates

- ISO 9001:2015 Quality Management System

- IATF 16949 Automotive Quality Management

- ISO 14001 Environmental Management System

- CE Certification for European Market

Packaging and Shipping

We ensure secure packaging to protect your products during transit:

- Custom-designed boxes or pallets

- Foam inserts for delicate parts

- Vacuum-sealed bags for moisture protection

- On-time delivery with tracking

FAQ

Q: What is the minimum order quantity (MOQ) for the products?

A: Our MOQ is typically 100 pieces, but we can accommodate smaller orders for prototyping or special requirements.

Q: Can you provide custom designs for the products?

A: Absolutely! We offer full customization services, from design optimization to production, based on your specifications.

Q: What is the lead time for a typical order?

A: Lead times vary based on order size and complexity, but generally range from 3-6 weeks. We'll provide a specific timeline upon order confirmation.

Q: Do you offer any surface treatment options for the castings?

A: Yes, we provide various surface treatments including anodizing, powder coating, and polishing to meet your specific needs.

Contact Us

Ready to elevate your projects with our premium aluminum alloy clamp castings? Contact Zhejiang Fudebao Technology Co., Ltd. today for a quote or to discuss your custom requirements.

Email: hank.shen@fdbcasting.com

Experience the Fudebao difference – where precision meets innovation in product solutions.

_1756349002499.webp)

_1756348356531.webp)

_1756348489473.webp)

_1756349146076.webp)

_1756349696500.webp)

_1756349957728.webp)

_1756350046757.webp)