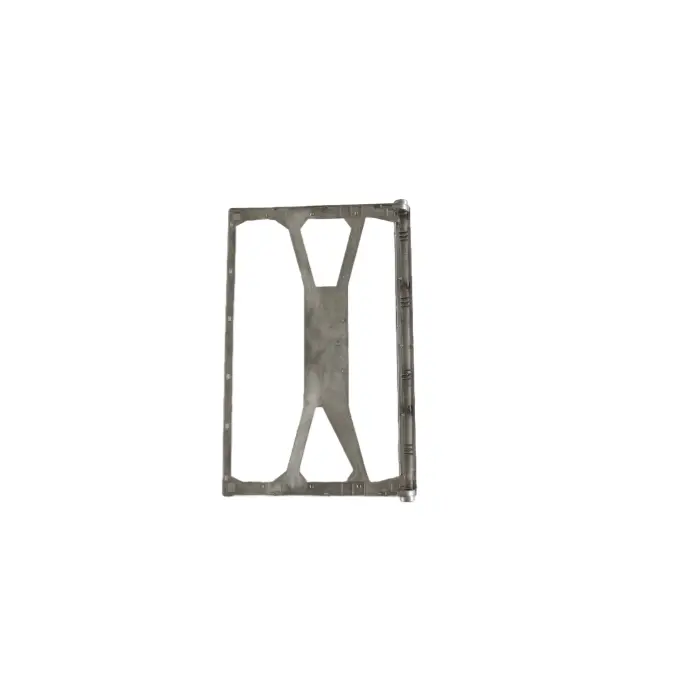

Optimizing Die Design and Material Selection

Innovative Die Design Techniques

Achieving superior dimensional accuracy in aluminum die cast parts begins with meticulous die design. Advanced CAD/CAM software enables engineers to create intricate, precision-engineered dies that account for material flow, thermal expansion, and shrinkage. By incorporating features such as optimized gating systems, strategically placed overflow wells, and carefully calculated draft angles, designers can minimize defects and enhance dimensional stability. Moreover, the use of conformal cooling channels within the die can promote uniform solidification, reducing the risk of warpage and improving overall part consistency.

Material Selection for Enhanced Performance

Choosing the right aluminum alloy is paramount in controlling dimensional accuracy in aluminum die casting. Different alloys exhibit varying shrinkage rates, fluidity, and mechanical properties. For instance, alloys with lower shrinkage rates, such as A380 or A383, can help maintain tighter tolerances during the cooling process. Additionally, considering the specific requirements of the end product, such as strength, corrosion resistance, or thermal conductivity, can guide the selection of an optimal alloy that not only meets functional needs but also facilitates better dimensional control during casting.

Die Maintenance and Longevity

Regular die maintenance plays a crucial role in preserving dimensional accuracy over extended production runs. Implementing a proactive maintenance schedule, including routine inspections, cleaning, and refurbishment, helps prevent wear and damage that could compromise part dimensions. Advanced surface treatments, such as nitriding or PVD coatings, can enhance die longevity and maintain consistent surface quality, contributing to improved dimensional stability of the cast parts. Furthermore, careful monitoring of die temperature and lubrication during production helps maintain optimal casting conditions and consistent part dimensions.

Process Control and Advanced Casting Techniques

Precision Temperature Management

Maintaining precise control over temperature throughout the die casting process is essential for dimensional accuracy. State-of-the-art thermal management systems, including advanced furnace controls and die temperature regulators, ensure that both the molten aluminum and the die are at optimal temperatures. This precision helps minimize thermal stress and uneven solidification, which can lead to dimensional variations. Implementing real-time temperature monitoring and feedback systems allows for immediate adjustments, ensuring consistency across production batches.

High-Pressure Die Casting Innovations

Advancements in high-pressure aluminum die casting technology have significantly improved dimensional accuracy capabilities. Modern machines equipped with servo-driven injection systems offer precise control over shot speed and pressure profiles. This level of control allows for optimized filling patterns and reduced turbulence, minimizing the risk of porosity and ensuring more uniform part dimensions. Additionally, vacuum-assisted die casting techniques can further enhance part quality by reducing air entrapment, resulting in denser, more dimensionally stable components.

Computer-Aided Simulation and Process Optimization

Leveraging cutting-edge simulation software enables manufacturers to predict and optimize the casting process before physical production begins. These tools simulate mold filling, solidification, and cooling, allowing engineers to identify potential issues such as shrinkage cavities or hot spots that could affect dimensional accuracy. By iteratively refining process parameters in the virtual environment, manufacturers can develop robust casting strategies that consistently produce parts within tight tolerances. This digital approach not only improves accuracy but also reduces development time and material waste.

Quality Control and Post-Casting Operations

Advanced Metrology and Inspection Techniques

Implementing rigorous quality control measures is crucial for maintaining dimensional accuracy in aluminum die casting parts. State-of-the-art metrology equipment, such as coordinate measuring machines (CMMs) and 3D laser scanners, enable precise measurement and verification of part dimensions. These tools can quickly capture complex geometries and generate detailed reports, allowing for rapid identification of any deviations from specifications. Additionally, in-line inspection systems utilizing machine vision technology can provide real-time monitoring of critical dimensions during production, enabling immediate corrective actions when necessary.

Precision Machining and Surface Finishing

While die casting can produce near-net-shape parts, achieving the highest levels of dimensional accuracy often requires post-casting machining operations. Advanced CNC machining centers, equipped with high-speed spindles and multi-axis capabilities, can perform precise secondary operations to refine critical features and achieve tight tolerances. Implementing strategies such as fixture design optimization and tool path programming tailored for die cast materials ensures consistent and accurate machining results. Moreover, carefully controlled surface finishing processes, such as shot blasting or polishing, can further enhance dimensional consistency while improving surface quality.

Statistical Process Control and Continuous Improvement

Implementing statistical process control (SPC) methodologies is essential for maintaining and improving dimensional accuracy over time. By collecting and analyzing data on key process parameters and part measurements, manufacturers can identify trends, detect early signs of process drift, and implement corrective actions proactively. This data-driven approach enables continuous refinement of casting parameters, die designs, and quality control procedures. Furthermore, fostering a culture of continuous improvement, where operators and engineers collaborate to address challenges and implement best practices, contributes to ongoing enhancements in dimensional accuracy and overall part quality.

Conclusion

Controlling dimensional accuracy in aluminum die casting parts requires a comprehensive approach that integrates advanced technologies, meticulous process control, and continuous improvement efforts. By optimizing die design, implementing precise temperature management, leveraging computer-aided simulations, and utilizing state-of-the-art quality control measures, manufacturers can consistently produce high-precision aluminum components. As industries continue to demand tighter tolerances and more complex geometries, staying at the forefront of die casting technology and best practices will be crucial for meeting these evolving requirements and maintaining a competitive edge in the global market.

FAQs

What factors most significantly impact dimensional accuracy in aluminum die casting?

Key factors include die design, material selection, temperature control, injection parameters, and post-casting operations.

How does alloy selection affect dimensional accuracy?

Different aluminum alloys have varying shrinkage rates and fluidity, which can impact final part dimensions.

Can vacuum-assisted die casting improve dimensional accuracy?

Yes, it can reduce air entrapment, leading to denser parts with more consistent dimensions.

What role does simulation software play in achieving dimensional accuracy?

It helps optimize process parameters and identify potential issues before physical production, improving overall accuracy.

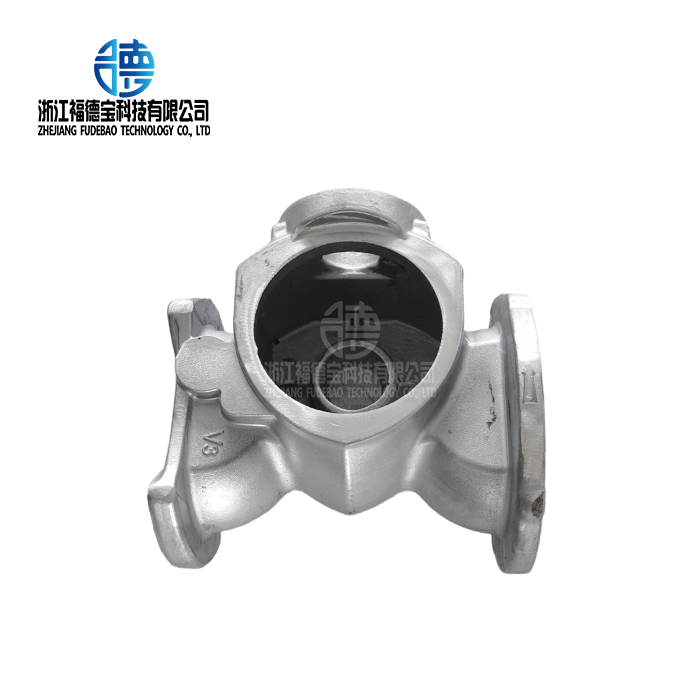

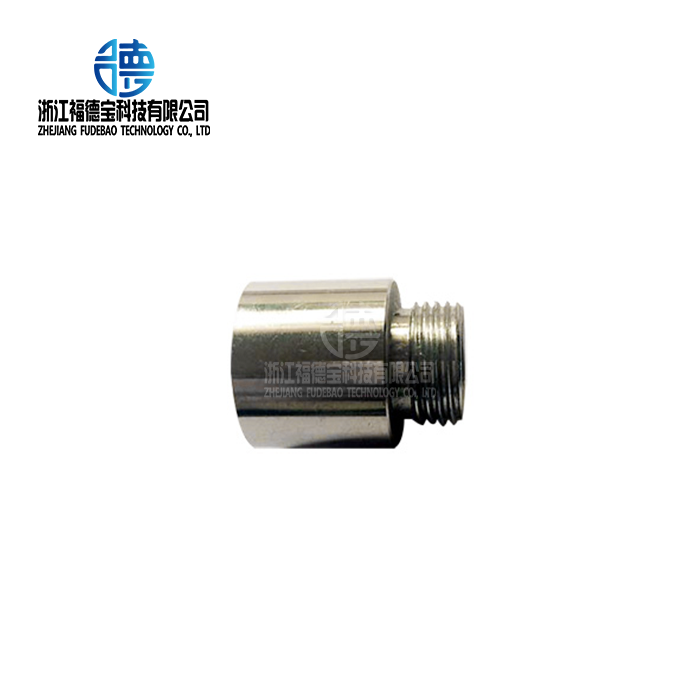

Expert Aluminum Die Casting Solutions | Fudebao Technology

At Fudebao Technology, we specialize in delivering high-precision aluminum die cast parts with exceptional dimensional accuracy. Our state-of-the-art facilities and expert team ensure top-quality components for automotive, industrial, and medical applications. As a leading aluminum die casting manufacturer, we offer comprehensive solutions from design to finished products. Contact us at hank.shen@fdbcasting.com to discuss your precision casting needs.

References

Johnson, A. R. (2022). Advanced Die Design for Precision Aluminum Die Casting. Journal of Materials Engineering and Performance, 31(4), 2876-2890.

Zhang, L., & Wang, X. (2021). Thermal Management Strategies in High-Pressure Die Casting: A Comprehensive Review. International Journal of Heat and Mass Transfer, 168, 120954.

Chen, Y., Liu, Z., & Zhang, S. (2023). Innovative Approaches to Enhance Dimensional Accuracy in Aluminum Die Casting. Materials Today: Proceedings, 64, 1252-1258.

Smith, R. D., & Brown, K. L. (2022). Statistical Process Control in Modern Die Casting Operations. Quality Engineering, 34(2), 215-229.

Patel, N., & Rodriguez, M. (2021). The Role of Computer-Aided Simulation in Optimizing Die Casting Processes. Simulation Modelling Practice and Theory, 109, 102299.

Thompson, E. J., & Wilson, G. H. (2023). Advancements in Metrology for High-Precision Die Cast Component Inspection. Measurement Science and Technology, 34(6), 065007.

_1756346144394.webp)

_1756349794241.webp)

_1756352472762.webp)