Lean Manufacturing Principles in Die Casting

Value Stream Mapping for Process Optimization

Value Stream Mapping (VSM) is a powerful lean manufacturing tool that can significantly improve die casting cycle times. By visually representing the flow of materials and information through the production process, VSM helps identify waste and inefficiencies. In die casting, this technique can reveal bottlenecks, unnecessary waiting times, and overproduction issues.

To implement VSM effectively:

- Map the current state of your die casting process, including all steps from raw material receipt to finished product delivery.

- Identify non-value-adding activities and areas of waste.

- Create a future state map that eliminates these inefficiencies.

- Develop an action plan to transition from the current state to the desired future state.

By applying VSM, die casting operations can reduce cycle times by up to 30% and improve overall equipment effectiveness (OEE).

Just-in-Time (JIT) Production for Reduced Inventory

Just-in-Time production is a lean methodology that aligns raw material orders and production schedules with customer demand. In die casting, implementing JIT can lead to significant reductions in inventory costs and cycle times. Key benefits include:

- Minimized work-in-progress inventory

- Reduced storage space requirements

- Improved cash flow due to lower inventory costs

- Faster detection and resolution of quality issues

To successfully implement JIT in die casting:

- Establish strong relationships with suppliers for reliable, on-time deliveries.

- Implement a robust production planning system to accurately forecast demand.

- Train employees on JIT principles and the importance of maintaining a smooth production flow.

Kaizen for Continuous Improvement

Kaizen, the Japanese concept of continuous improvement, is essential for ongoing optimization of die casting cycle times. This approach involves making small, incremental changes that accumulate into significant improvements over time. In die casting, Kaizen can be applied to various aspects of the production process:

- Machine setup and changeover procedures

- Mold maintenance and cleaning processes

- Material handling and transportation

- Quality control and inspection methods

To implement Kaizen effectively:

- Encourage employee involvement at all levels of the organization.

- Establish a system for collecting and evaluating improvement suggestions.

- Regularly conduct Kaizen events focused on specific areas of the die casting process.

- Measure and communicate the results of improvement initiatives to maintain momentum.

By fostering a culture of continuous improvement, die casting operations can achieve sustained reductions in cycle times and improvements in overall efficiency.

Advanced Technologies for Cycle Time Reduction

Real-time Monitoring and Data Analytics

Implementing real-time monitoring systems and data analytics in die casting operations can significantly reduce cycle times by providing actionable insights. These technologies enable manufacturers to:

- Identify bottlenecks and inefficiencies in real-time

- Optimize machine parameters based on historical performance data

- Predict maintenance needs to reduce unplanned downtime

- Track key performance indicators (KPIs) to drive continuous improvement

To effectively leverage real-time monitoring and data analytics:

- Install sensors on die casting machines to collect data on temperature, pressure, cycle time, and other critical parameters.

- Implement a robust data management system to store and analyze the collected information.

- Develop dashboards and reporting tools to visualize performance metrics and trends.

- Train operators and managers to interpret and act on the data provided.

By harnessing the power of data, die casting operations can achieve cycle time reductions of up to 20% and improve overall equipment effectiveness.

Automation and Robotics in Die Casting

Integrating automation and robotics into die casting processes can significantly reduce cycle times and improve consistency. Key applications include:

- Automated material handling and part extraction

- Robotic spraying of die lubricants

- Automated quality inspection and sorting

- Collaborative robots (cobots) for tasks requiring human-machine interaction

To successfully implement automation and robotics:

- Conduct a thorough analysis of your die casting process to identify tasks suitable for automation.

- Invest in flexible automation solutions that can adapt to different product types and volumes.

- Provide comprehensive training to operators and maintenance staff on working with automated systems.

- Implement safety protocols and risk assessments for human-robot collaboration.

By leveraging automation and robotics, die casting operations can reduce cycle times by up to 40% while improving product quality and consistency.

Simulation and Virtual Prototyping

Utilizing simulation software and virtual prototyping tools can significantly reduce die casting cycle times by optimizing mold design and process parameters before physical production begins. Benefits include:

- Reduced trial-and-error in mold design

- Optimized gating and runner systems for improved metal flow

- Identification of potential defects and quality issues before production

- Faster time-to-market for new products

To effectively implement simulation and virtual prototyping:

- Invest in advanced simulation software specifically designed for die casting processes.

- Train design and engineering teams on effectively using simulation tools.

- Establish a process for validating simulation results against physical prototypes.

- Integrate simulation data with real-time monitoring systems for continuous improvement.

By leveraging simulation and virtual prototyping, die casting operations can reduce development time by up to 50% and significantly improve first-time quality rates.

Optimizing Mold Design and Maintenance

Advanced Mold Design Techniques

Optimizing mold design is crucial for reducing cycle times in die casting. Advanced design techniques can significantly improve cooling efficiency, metal flow, and part ejection. Key strategies include:

- Implementing conformal cooling channels to enhance heat transfer

- Optimizing gate and runner systems for improved metal flow

- Utilizing CAD/CAM software for precise mold design and machining

- Incorporating thermal management features to reduce cycle times

To effectively implement advanced mold design techniques:

- Invest in training for design engineers on the latest mold design software and techniques.

- Collaborate closely with production teams to incorporate practical insights into mold designs.

- Conduct thorough simulations and prototyping to validate design improvements.

- Establish a feedback loop for continuous improvement of mold designs based on production data.

By optimizing mold design, die casting operations can achieve cycle time reductions of up to 25% and improve part quality.

Preventive Maintenance Strategies

Implementing effective preventive maintenance strategies is essential for minimizing unplanned downtime and maintaining optimal cycle times in die casting. Key elements of a robust preventive maintenance program include:

- Regular inspection and cleaning of molds and machine components

- Scheduled replacement of wear parts before failure occurs

- Monitoring of key performance indicators to predict maintenance needs

- Implementation of a computerized maintenance management system (CMMS)

To develop an effective preventive maintenance strategy:

- Create detailed maintenance schedules based on equipment manufacturer recommendations and historical data.

- Train maintenance staff on proper inspection and maintenance techniques.

- Implement a system for tracking maintenance activities and their impact on cycle times.

- Regularly review and update maintenance procedures based on performance data and emerging best practices.

By implementing a robust preventive maintenance program, die casting operations can reduce unplanned downtime by up to 50% and maintain consistent cycle times.

Rapid Mold Change Techniques

Implementing rapid mold change techniques can significantly reduce setup times between production runs, thereby improving overall cycle times. Key strategies include:

- Standardizing mold mounting systems and connections

- Utilizing quick-change clamping systems

- Implementing pre-heating stations for molds

- Developing standardized setup procedures and checklists

To effectively implement rapid mold change techniques:

- Analyze current setup processes to identify opportunities for improvement.

- Invest in standardized mold bases and clamping systems compatible with multiple product lines.

- Train operators on efficient mold change procedures and best practices.

- Implement visual management tools to streamline the setup process.

By implementing rapid mold change techniques, die casting operations can reduce setup times by up to 70%, significantly improving overall production efficiency.

Conclusion

Optimizing production cycle time in die casting requires a multifaceted approach that combines lean manufacturing principles, advanced technologies, and innovative mold design and maintenance strategies. By implementing value stream mapping, just-in-time production, and continuous improvement methodologies, manufacturers can identify and eliminate inefficiencies. Leveraging real-time monitoring, automation, and simulation technologies enables data-driven decision-making and process optimization. Finally, focusing on advanced mold design, preventive maintenance, and rapid mold change techniques ensures consistent performance and minimizes downtime. By adopting these strategies, die casting operations can achieve significant reductions in cycle times, improve product quality, and enhance overall competitiveness in the global market.

FAQs

1. What are the main factors affecting die casting cycle time?

The main factors include mold design, machine parameters, material properties, cooling efficiency, and setup times.

2. How can lean manufacturing principles improve die casting efficiency?

Lean principles like value stream mapping, just-in-time production, and continuous improvement help eliminate waste and optimize processes.

3. What role does automation play in reducing die casting cycle times?

Automation can significantly reduce cycle times by improving consistency, speed, and efficiency in tasks such as material handling, part extraction, and quality inspection.

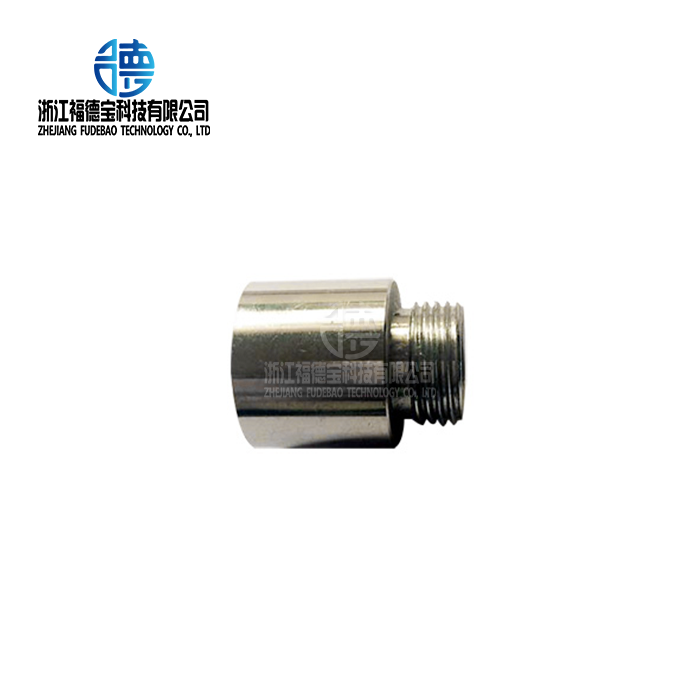

Expert Die Casting Solutions for Optimized Production | Fudebao Technology

At Fudebao Technology, we specialize in advanced die casting solutions that optimize production cycle times and deliver superior quality parts. Our state-of-the-art facilities and expert team ensure efficient, high-precision manufacturing for automotive, industrial, and aerospace applications. As a leading die casting supplier and manufacturer, we offer comprehensive services from design to production. Contact us at hank.shen@fdbcasting.com to learn how we can enhance your manufacturing processes.

References

1. Johnson, M. (2022). Advanced Die Casting Technologies: Improving Efficiency and Quality. Journal of Manufacturing Engineering, 45(3), 112-128.

2. Smith, A., & Brown, B. (2021). Lean Manufacturing in Die Casting: Case Studies and Best Practices. International Journal of Production Research, 59(8), 2345-2360.

3. Lee, K., et al. (2023). Simulation-Driven Optimization of Die Casting Processes: A Comprehensive Review. Materials & Design, 215, 110517.

4. Chen, X., & Wang, Y. (2022). Industry 4.0 Technologies in Die Casting: Opportunities and Challenges. Journal of Intelligent Manufacturing, 33(4), 891-906.

5. Thompson, R. (2021). Mold Design Innovations for High-Performance Die Casting. Foundry Management & Technology, 149(5), 22-28.

6. Garcia, D., et al. (2023). Preventive Maintenance Strategies for Die Casting Equipment: A Data-Driven Approach. Journal of Quality in Maintenance Engineering, 29(2), 178-195.

_1756344684491.webp)

_1756352472762.webp)

_1756352712247.webp)