Best Low Pressure Cast Parts for Structural Use

2026-01-17

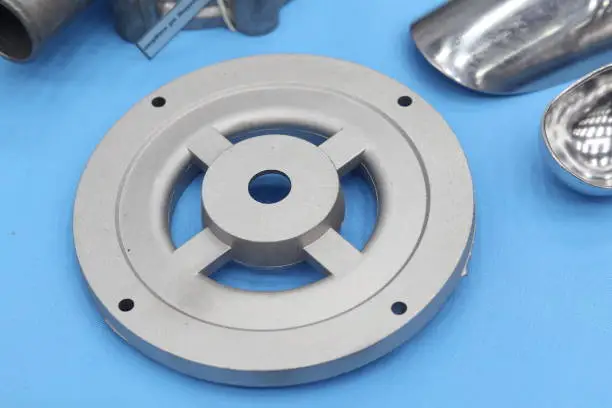

Procurement experts are looking for the best low pressure cast parts for structural application, and they require parts that are reliable, strong, and have precise dimensions. The chosen production technique for creating high-integrity structural components for industrial, automotive, and aerospace applications is low pressure casting technology. Compared to conventional casting techniques, this precise process produces components with better mechanical qualities, less porosity, and improved surface polish, making it the best option for demanding structural applications.

Understanding Low Pressure Casting for Structural Parts

Compared to gravity or sand casting techniques, low pressure casting produces higher density and fewer flaws by pushing molten metal into molds under regulated low pressure, usually between 0.1 and 1 bar. Melted metal is first kept in a sealed furnace that is linked to the mold cavity via a riser tube. Pressure causes the metal to climb through the tube and fill the mold from bottom to top, decreasing oxidation and removing turbulence.

Process Fundamentals and Working Principles

Low pressure casting differs from other processes due to its controlled filling mechanism. This method preserves mild filling conditions that protect metal integrity, in contrast to high-pressure die casting, which employs tremendous pressure (150–1200 bar). Parts with improved mechanical qualities are produced by the progressive filling, which decreases porosity and lowers air entrapment. Metallurgical quality is influenced by temperature control at every stage of the process; careful regulation of cooling rates guarantees the best possible grain structure development.

Material Selection for Structural Applications

It becomes clear why some materials perform well in demanding tasks when one understands important alloys that are often utilized in structural applications. Aluminum alloys have remarkable corrosion resistance and strength-to-weight ratios, especially A356 and A380. These alloys are perfect for aircraft structural parts and automobile chassis components since they retain their qualities under a range of temperatures. For some applications, magnesium alloys provide even lighter substitutes that are nevertheless strong enough.

Important factors that affect dimensional stability in low pressure casting are highlighted in the thorough process overview, which covers everything from mold preparation to controlled cooling. In order to guarantee constant part quality over production runs, mold design considerations include gate location, cooling channel optimization, and thermal management techniques.

Comparison with Alternative Casting Methods

When comparing gravity casting to low pressure casting, there are notable benefits in the manufacturing of structural components. Gravity casting uses just gravity, which often leads to increased porosity levels and partial filling. Although it works well for big components, sand casting lacks the accuracy and surface quality that low pressure techniques may provide. Due to high-pressure injection and quick cooling, die casting provides speed at the expense of material qualities.

Advantages and Benefits of Low Pressure Casting in Structural Applications

Compared to conventional casting methods, low pressure casting has many benefits, such as better mechanical qualities, decreased porosity, and increased dimensional accuracy—all of which are crucial for structural components. By minimizing turbulence, the controlled filling process lessens gas entrapment and oxide production, which are significant problems with conventional casting techniques. As a consequence, pieces with improved tensile strength—typically 15–20% higher than their gravity cast counterparts—are produced.

Superior Mechanical Properties and Quality

Components with improved fatigue resistance and impact strength are produced by the mild filling action, which maintains the microstructure of aluminum alloy. Generally speaking, porosity levels stay around 2%, as opposed to 5-8% in gravity casting, which immediately results in increased structural integrity. Without the need for further machining, surface finish quality may attain Ra values of 1.6–3.2 μm, which lowers the need for post-processing and manufacturing expenses overall.

Dimensional precision meets automotive and aerospace criteria without requiring significant machining procedures, regularly achieving tolerances within ±0.3mm. In complicated geometries, the controlled solidification process minimizes warpage and distortion by removing hot spots and lowering internal stress.

Cost Efficiency and Production Benefits

For medium-volume production runs, there are significant cost benefits when comparing low pressure casting versus high pressure die casting. Low pressure methods use simpler molds and equipment, requiring less initial investment than die casting, which needs costly tooling and high-pressure equipment. Production cycles provide higher material use with less waste creation, albeit being lengthier than die casting.

Because less pressure is used and heat control is improved, the energy consumption per part is still lower than with other approaches. The method offers flexibility for a wide range of product portfolios by accommodating different alloy compositions without requiring major equipment adjustments.

Quality Control and Defect Prevention

Controlled process settings in low pressure casting efficiently reduce common defects such as inclusions, shrinkage porosity, and cold shuts. Non-destructive testing procedures, temperature monitoring, and real-time pressure monitoring are examples of quality control techniques. These steps guarantee that procurement specialists can get dependable, flawless castings that satisfy strict structural requirements while maintaining a constant level of manufacturing quality.

How to Choose the Best Low Pressure Cast Parts for Structural Use?

It is necessary to carefully consider a number of criteria that directly affect performance and cost-effectiveness when choosing the best low pressure cast components. Clearly outlining procurement needs, such as strength standards, durability expectations, accuracy tolerances, delivery schedules, minimum order numbers, and financial restrictions, is the first step in the selection process. These criteria serve as the basis for developing part specifications and evaluating suppliers.

Defining Technical Requirements

Certain mechanical qualities, which vary depending on the sector and application, are required for structural applications. Aerospace components must have excellent strength-to-weight ratios and temperature stability, while automotive components must be crash-resistant and fatigue-resistant. Applications for industrial equipment place a high value on robustness and resistance to corrosion. Procurement teams may create reasonable specifications and find qualified suppliers with related expertise by having a clear understanding of these criteria.

Early in the procurement process, material certification criteria, such as adherence to ASTM, ISO, or industry-specific standards, must be set. For applications in regulated sectors, dimensional inspection reports, heat treatment certificates, and traceability paperwork become essential.

Supplier Evaluation Criteria

Procurement managers are required to assess suppliers according to their reputation, production capacity, quality control certificates, and technical proficiency in pressure die casting procedures. Equipment capacity, engineering support capabilities, quality management systems, and prior expertise with comparable structural components are important evaluation criteria. Actual production capabilities and quality control measures are revealed by site audits.

Supply chain resilience and financial stability are becoming more crucial factors to take into account. Long-term collaborations are less risky for suppliers with diverse client bases and strong backup plans. Lead times and logistical costs may be impacted by geographic proximity, especially for high-volume applications.

Customization and Manufacturing Flexibility

By using customization tactics, customers may take advantage of specialist manufacturers' scalable manufacturing and cutting-edge technical assistance for custom structural components. Flexible producers are able to adapt to changes in volume, prototype development, and design without incurring large costs. During stages of product development and changes in market demand, this flexibility becomes useful.

These insights allow for reliable delivery and cost-effective sourcing that meets the technical requirements of high-performance structural applications.

Real-World Applications and Case Studies of Low Pressure Cast Structural Parts

Automotive, aerospace, construction, and industrial equipment manufacture are just a few of the high-demand industries where low pressure casting is widely used. The technology's flexibility to various technical needs is shown by its ability to produce complicated structural components, such as aircraft frame elements and automobile suspension components.

Automotive Industry Applications

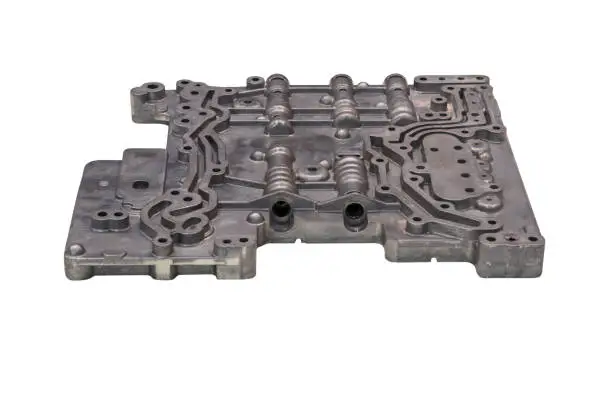

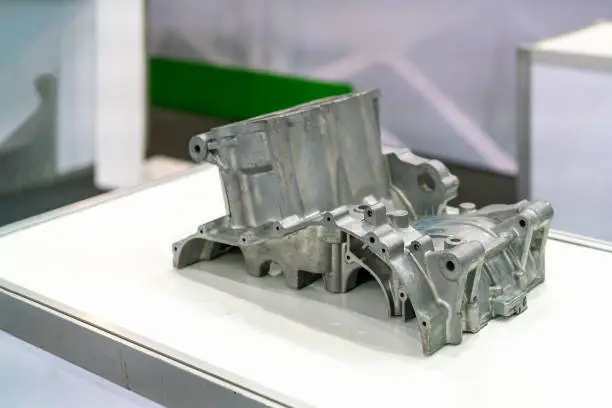

Low pressure cast aluminum components are being used more and more by automakers to save weight without sacrificing structural integrity. The method produces intricate interior geometries with uniform wall thickness, which is advantageous for suspension arms, engine brackets, transmission housings, and chassis parts. When compared to steel counterparts, major car suppliers estimate weight reductions of 30–40% without sacrificing durability or crash performance.

The technology for battery housing components, where dimensional precision and thermal management qualities become crucial, is especially valued by producers of electric vehicles. Integrated cooling channels and mounting features are made possible by the casting technique, which simplifies assembly and enhances thermal performance.

Aerospace and Defense Applications

The technology's capacity to create lightweight, highly-strengthened structural elements that satisfy strict certification standards is shown by aerospace applications. Avionics housings, landing gear parts, and aircraft seat frames show how the technique may meet strict tolerances while preserving the material traceability and quality documentation needed by aviation regulators.

Practical Case Study: Automotive Suspension Component

Traditional forged suspension arms that needed a lot of machining and many assembly steps presented difficulties for a top automotive tier-1 supplier. In comparison to steel alternatives, the component had to satisfy weight reduction requirements of 25% while withstanding 2 million fatigue cycles. Because of porosity problems, pieces made using traditional casting techniques lacked adequate mechanical qualities.

These production issues were resolved by using A356 aluminum alloy and low pressure casting. Porosity issues were resolved by the carefully regulated filling procedure, which also produced the necessary mechanical qualities. Near-net-shape casting resulted in considerable cost reductions by reducing machining processes by 60%. The finished component demonstrated a measurable return on investment via increased part durability and cost savings, surpassing fatigue criteria while reaching the desired weight reduction.

Compared to forged alternatives, post-implementation study showed a 15% cheaper total cost of ownership, which included lower tooling costs, faster lead times, and better material use. Increased customer satisfaction ratings and a 40% decrease in warranty claims were examples of quality improvements.

Future Innovations and Technology Trends

New alloy creations, sophisticated process monitoring systems, and equipment improvements in low pressure casting are examples of upcoming casting technology advancements that will influence next-generation structural production. Predictive quality control is made possible by the integration of artificial intelligence, while complicated mold geometries and quick prototype creation are supported by additive manufacturing. These developments establish low pressure casting as a critical technique for new uses in modern manufacturing, renewable energy systems, and electric automobiles.

Partner with Fudebao Technology for Premium Structural Casting Solutions

One of the leading producers of low pressure castings, Zhejiang Fudebao Technology Co., Ltd. specializes in producing superior structural elements for challenging applications. Our extensive product ranges, which serve the worldwide automotive, industrial equipment, aerospace, and machinery manufacturing industries, include castings made of aluminum alloy, copper alloy, and stainless steel. In order to become a leading firm in China's aluminum foundry sector, the company has moved from middleman collaboration to direct supply ties with global brands, such as American HAAS automated machine tools and ESS energy storage batteries.

Advanced Manufacturing Capabilities

The main pieces of equipment at our facility, which cover the whole process from melting through casting to finishing and surface treatment, include high-speed machining centers, CNC lathes, pressure casting machines, and die casting systems. With precise tolerances up to ±0.05mm, this integrated technique enables one-stop delivery from blank components to completed products, meeting strict specifications for medical equipment housings, automotive precision parts, and aerospace components.

Every step of the production process places a strong emphasis on quality control, and consistent product quality is ensured by thorough inspection procedures and certification compliance. Superior mechanical qualities and dimensional stability may be achieved by optimizing alloy compositions and heat treatment techniques for particular structural applications thanks to advanced metallurgical knowledge.

Technical Excellence and Customer Support

In order to assist clients achieve the best possible component performance at the lowest possible cost, engineering support services include design optimization, prototype creation, and manufacturing process consultancy. In order to comprehend particular application needs and create unique solutions that surpass expectations, the technical team works closely with procurement specialists.

International standards-aligned quality management systems provide regulated companies the certification compliance and traceability documents they need. In order to preserve competitive advantages in the production of structural components, continuous improvement programs concentrate on process optimization, equipment improvements, and technology adoption.

Conclusion

For structural components that need outstanding quality, dimensional precision, and mechanical qualities, low pressure casting is the best production technique. The technique is the favored option for industrial, automotive, and aerospace applications because to its regulated filling process, excellent material usage, and reliable quality output. When sourcing structural components, procurement professionals benefit from knowing the application concerns, supplier assessment standards, and process principles. Collaborating with seasoned producers such as Fudebao Technology guarantees access to cutting-edge capabilities, technological know-how, and dependable supply chain support—all of which are necessary for project success.

FAQ

How long does it usually take to get low pressure cast structural parts?

Depending on the complexity of the item and the amount of orders, lead times for manufacturing quantities of low pressure cast parts usually vary from 4 to 8 weeks. Tooling preparation takes two to three weeks, and first casting trials take one week. Expedited scheduling may be able to fulfill rush requests, but the cost may increase.

In comparison to other techniques, how does low pressure casting improve mechanical strength?

Through regulated filling that reduces porosity and maintains alloy microstructure, low pressure casting improves mechanical strength. The method usually lowers porosity levels below 2% while increasing tensile strength by 15% to 20% when compared to gravity casting. Cast components are weakened by oxide production and gas trapping, which are avoided by gentle filling.

Can complicated component geometries be accommodated by low pressure casting?

The method is excellent at creating complicated features, internal cavities, and complex geometries with variable wall thickness. Even in difficult designs, full mold cavity filling is guaranteed by controlled pressure filling. Undercuts, internal cooling channels, and integrated mounting elements that minimize assembly needs are examples of design flexibility.

Contact Fudebao Technology for Superior Low Pressure Casting Solutions

Find out how Fudebao Technology's sophisticated low pressure casting capabilities can turn your structural component needs into high-performing solutions. Our skilled engineering team serves automotive, aerospace, and industrial applications globally, specializing in aluminum alloy structural parts with fine tolerances up to ±0.05mm. As a top provider of low pressure casting, we provide outstanding results by fusing cutting-edge production machinery with extensive quality control procedures. To discuss your unique demands and get comprehensive technical recommendations catered to your structural application requirements, get in touch with our technical experts at hank.shen@fdbcasting.com.

References

Campbell, John. "Complete Casting Handbook: Metal Casting Processes, Metallurgy, Techniques and Design." Butterworth-Heinemann Publications, 2015.

Stefanescu, Doru Michael. "Science and Engineering of Casting Solidification." Springer International Publishing, 2017.

American Foundry Society. "Aluminum Casting Technology Standards and Best Practices for Structural Applications." AFS Technical Publications, 2019.

International Organization for Standardization. "ISO 16220:2005 - Magnesium and Magnesium Alloys - Unalloyed Magnesium - Specifications." ISO Technical Committee, 2020.

ASM International Handbook Committee. "ASM Handbook Volume 15: Casting Processes and Technologies." ASM International Materials Engineering, 2018.

Zhang, Wei and Liu, Ming. "Advanced Low Pressure Casting Techniques for Automotive Structural Components." Journal of Manufacturing Science and Engineering, 2021.

_1756352561845.webp)

_1756361323684.webp)