How to Choose a Reliable Aluminum Die Casting Supplier?

2026-01-17

It is important to carefully consider quality certifications, manufacturing capacity, material knowledge, and the possibility of a long-term cooperation when selecting a trustworthy aluminum die casting provider. The ideal supplier should consistently provide lightweight, long-lasting components with accuracy, all the while keeping open lines of communication and offering low prices. Important elements include ISO certifications, track records of success in your business, sophisticated equipment capabilities, and extensive quality control systems that guarantee material integrity and dimensional precision throughout the manufacturing process.

Understanding the Importance of Choosing the Right Aluminum Die Casting Supplier

In today's cutthroat industrial environment, choosing the best aluminum die casting supplier is one of the most important choices procurement executives must make. From automotive to aerospace applications, this decision has a direct influence on supply chain efficiency, manufacturing schedules, and product quality.

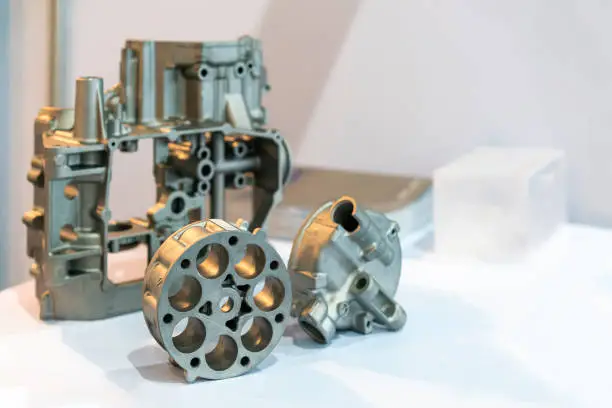

For the demands of contemporary production, the aluminum die casting technique produces accurate, lightweight parts. The supplier's experience becomes crucial when automakers need engine housings with precise dimensions or aerospace firms need structural components that fulfill strict weight criteria. Poor supplier selection often results in expensive manufacturing delays, subpar products, and diminished product performance, all of which may harm a brand's image.

Dealing with opaque pricing structures, managing erratic lead times, and negotiating uneven quality standards are common procurement issues. When suppliers don't maintain sufficient quality control systems or don't have the necessary certifications, these problems become worse. Engineering managers and procurement directors are aware that supplier dependability encompasses long-term relationship value in addition to initial cost concerns.

By guaranteeing on-time delivery, lowering manufacturing defects, and maintaining open lines of communication across project lifecycles, a trustworthy supplier fortifies the whole supply chain. Reduced total expenses, better product performance, and more customer satisfaction are all results of this dependability. During the design stages, quality suppliers also provide technical assistance, which helps to optimize part designs for manufacturing while upholding performance standards.

Key Criteria for Evaluating Aluminum Die Casting Suppliers

A thorough assessment framework that addresses many important aspects is necessary for an effective supplier evaluation. Procurement teams are certain to find partners that can satisfy both short-term demands and long-term strategic goals thanks to this methodical approach.

Quality Assurance and Certifications

Quality certifications are essential markers of process consistency and supplier dependability. Industry-specific standards such as AS9100 for aerospace or TS 16949 for automotive indicate specialist competence, while ISO 9001 certification shows dedication to quality management systems. These certifications guarantee that suppliers maintain high standards throughout their operations by requiring frequent audits and ongoing improvement.

Coordinate measuring devices, automated inspection systems, and statistical process control are examples of advanced quality control systems. Material certifications, dimensional reports, and process capacity assessments are just a few examples of the comprehensive quality paperwork that suppliers should provide. For automotive suppliers, PPAP (Production Part Approval Process) paperwork is crucial since it guarantees that components fulfill specifications prior to full production.

Material Expertise and Alloy Selection

Comprehending the characteristics and uses of aluminum alloys in aluminum die casting sets seasoned vendors apart from simple casting processes. Different alloys have different properties in terms of machinability, strength, and resistance to corrosion. A380 aluminum offers greater die filling capabilities for intricate geometries, whereas A356 aluminum offers good castability and moderate strength.

Skilled vendors assist clients in choosing an alloy according to certain application specifications. They are aware of the behavior of various alloys during surface treatment, machining, and casting. This knowledge maximizes part performance for planned applications and avoids expensive material selection mistakes.

Production Capacity and Flexibility

The volume and delivery expectations of the client must be met by the production capability. In order to manage both prototype numbers and large-scale production runs, suppliers must exhibit scalability. Part size restrictions and accuracy capabilities are directly impacted by equipment capabilities, such as die casting machine tonnage ranges and machining center parameters.

Cost effectiveness is maintained by accommodating different demand patterns via flexible batch manufacturing. Diverse equipment portfolios allow suppliers to adjust to varying item geometries and production volumes without sacrificing delivery timeliness or quality. This adaptability is especially useful when new products are introduced or when demand varies seasonally.

Comparing Aluminum Die Casting with Alternative Manufacturing Processes

Procurement experts may make well-informed selections based on cost and application requirements by having a thorough understanding of manufacturing process options. Each technique has unique benefits and drawbacks that affect the properties of the finished product and the economics of manufacturing.

Die Casting versus Sand Casting

High-precision products with superior surface finishes and precise dimensional tolerances are produced by aluminum die casting with great success. Sand casting is unable to produce delicate features and complicated geometries with thin walls. For medium- to high-volume applications, die casting also provides better manufacturing speeds, which considerably lowers costs per unit.

Large pieces, low-volume manufacturing, and applications needing certain mechanical qualities that may be achieved by heat treatment can all benefit from sand casting. The method allows for design alterations without requiring costly tooling changes and accommodates a variety of aluminum alloys. However, in order to get exact dimensions and appropriate surface finishes, sand casting usually needs extra machining.

Material Comparisons: Aluminum versus Alternatives

Thermal conductivity, corrosion resistance, and strength-to-weight ratio are all well balanced by aluminum die casting. Although zinc die casting offers better surface polish and dimensional precision, it lacks the strength and heat resistance of aluminum. Even less weight is achieved using magnesium casting, although handling difficulties and increased material costs are associated with it.

Although plastic injection molding gives design freedom and lowers material costs, it cannot match the strength, electrical conductivity, or temperature resistance of metal casting. When compared to alternatives to aluminum casting, steel machining offers maximum strength but greatly increases weight and material costs.

Precision and Tolerance Considerations

Compared to sand casting or investment casting, die casting produces tighter tolerances, usually retaining ±0.1mm accuracy on most dimensions. Through secondary procedures, sophisticated vendors with precise machining capability may attain tolerances of ±0.05mm. This accuracy decreases the need for downstream processing and removes assembly problems.

While preserving the intrinsic benefits of aluminum, post-casting machining increases the possibilities for accuracy. complicated features that casting alone cannot provide, such as threaded holes, precise bores, and complicated surface contouring, are made possible by CNC machining centers. While maintaining dimensional precision, integrated casting and machining procedures maximize production efficiency.

How to Verify and Build Trust with Potential Suppliers?

Systematic verification procedures that extend beyond preliminary capability evaluations are necessary for developing supplier partnerships. Long-term relationship success and reliable quality delivery are ensured by building trust via useful assessment techniques.

Sample Evaluation and Prototyping

Physical samples provide verifiable proof of supplier competencies and quality requirements. Ask for examples that meet the same level of accuracy and complexity as the apps you want to use. When required, conduct independent testing to assess material characteristics, surface finish quality, and dimensional correctness.

The creation of prototypes demonstrates the technical problem-solving skills and responsiveness of suppliers. Examine how suppliers respond to design difficulties, make suggestions for enhancements, and keep in touch throughout the development stages. Capabilities for rapid prototyping point to sophisticated machinery and adaptable manufacturing schedules that help launch innovative products.

Technical Support Assessment

Project success in aluminum die casting is significantly impacted by the quality of engineering assistance, especially throughout the design optimization stages. Assess suppliers' capacity to provide advice on design for manufacturing, recommend ways to save costs, and resolve technical issues. Production delays are avoided and part designs are optimized for casting efficiency by responsive technical teams.

Effective communication becomes essential for interactions with foreign suppliers. Evaluate documentation quality, time zone accommodations, and language proficiency. Misunderstandings that result in poor quality or delayed delivery are avoided with clear communication. Proactive issue reporting and frequent progress reports show a supplier's dedication to client success.

Track Record and References

Experience in your industry shows that you understand the particular needs and standards of quality. While aerospace suppliers must exhibit knowledge with AS9100 regulations and material traceability systems, automotive suppliers should exhibit competence with PPAP paperwork.

Beyond promotional materials, client references provide insights into the real performance of suppliers. Speak with current clients to learn about delivery dependability, consistency in quality, and the efficiency of issue solving. Long-term client connections are a sign of a supplier's dependability and dedication to ongoing development.

Sustainability and Environmental Standards

As businesses adopt sustainable manufacturing techniques, environmental responsibility has a growing impact on supplier selection choices. Examine the waste reduction plans, energy efficiency projects, and recycling programs offered by suppliers. Although aluminum is naturally sustainable due to its recyclable nature, supplier practices have a big influence on the material's total environmental impact.

ISO 14001 and other sustainability certifications show methodical methods to environmental management. Suppliers that are dedicated to lessening their influence on the environment often use energy-efficient machinery, maximize the use of materials, and take part in recycling initiatives for aluminum. These procedures may lower long-term expenses while also supporting company sustainability objectives.

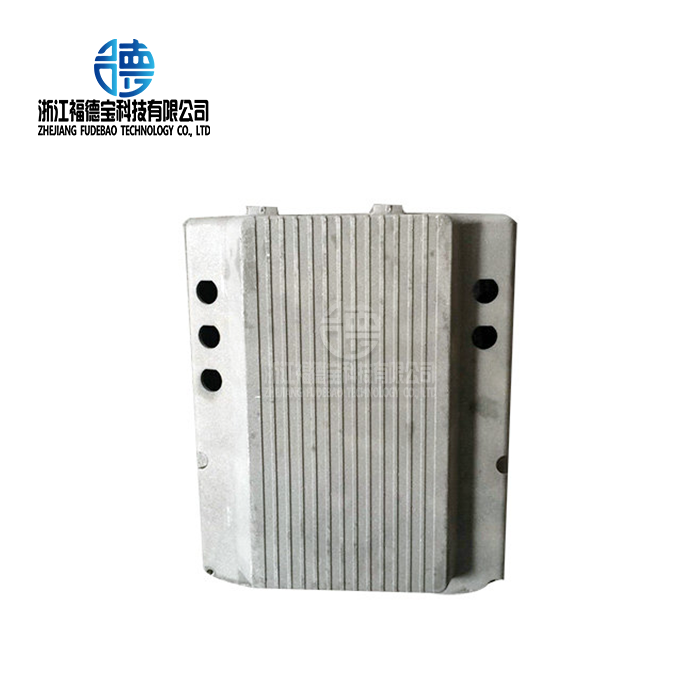

Fudebao Technology: Your Trusted Aluminum Die Casting Manufacturing Partner

Serving international markets in the automotive, industrial equipment, machinery manufacturing, and aerospace industries, Zhejiang Fudebao Technology Co., Ltd. is a prime example of expertise in precision machining and aluminum die casting. Our extensive manufacturing capabilities cover every step of the production process, from the melting of raw materials to the delivery of completed components.

High-speed machining centers, CNC lathes, low-pressure casting machines, and precision die casting systems are among the cutting-edge pieces of equipment housed at our state-of-the-art facility. Complete "melting-casting-finishing-surface treatment" activities may be carried out under one roof thanks to this integrated method, which guarantees quality control and effective delivery. We satisfy strict specifications for aerospace components, medical equipment housings, and automotive precision parts by maintaining dimensional accuracy up to ±0.05mm.

Our increasing market awareness and technological skills are shown by the company's transition from middleman collaboration to direct supply agreements with global brands such as American HAAS automation machine tools and ESS energy storage batteries. This development demonstrates our dedication to become a leading company in China's aluminum foundry sector.

Our knowledge of various copper alloys, stainless steel materials, and aluminum alloys enables us to provide clients complete metal casting solutions. We modify our procedures in accordance with our understanding of the particular needs of various sectors. Aerospace companies depend on our sophisticated inspection skills and material traceability systems, while automotive clients benefit from our TS 16949 quality systems and PPAP documentation capabilities.

Through organized quality control procedures and ongoing improvement projects, quality assurance continues to be essential to our business operations. Throughout project lifecycles, from early design consulting to production optimization and delivery, our skilled engineering staff offers technical assistance. This cooperative strategy guarantees that clients obtain the best possible solutions that satisfy performance standards and are economical.

Conclusion

A thorough assessment of quality certificates, manufacturing capacity, technical know-how, and the possibility of a long-term collaboration are necessary when choosing a trustworthy supplier for aluminum die casting. Effective procurement choices strike a compromise between short-term financial concerns and long-term value generation via dependable quality, consistent delivery, and helpful technical assistance. ISO certifications, industry-specific expertise, sophisticated equipment capabilities, and proven track records in related applications are important evaluating factors. To make sure the supplier's skills match the declared criteria, the verification procedure should include reference checks, technical support evaluation, and physical sample evaluation. Establishing trust by open communication and cooperative problem-solving lays the groundwork for fruitful, long-term collaborations that promote operational excellence and corporate expansion.

FAQs

What factors affect the cost of aluminum die casting?

The choice of aluminum alloy, part complexity, manufacturing volume, and necessary finishing processes are some of the factors that affect pricing. Intricate tooling for complex geometries raises initial costs, but economies of scale usually result in lower per-unit price for larger quantities. Although they increase total prices, secondary procedures like CNC machining, surface treatments, and quality checks improve the functioning and look of parts.

What is the average lead time for projects using aluminum die casting?

Production schedule, tooling needs, and project complexity all affect lead times. Order quantities and existing facility capacity determine production timing, whereas new tooling development normally takes 4–8 weeks. Although this often entails extra price, accelerated scheduling may be used to fulfill rush requests.

Can suppliers manage fast prototyping and unique designs?

Rapid prototype capabilities using soft tooling or 3D printing are becoming more and more available from contemporary aluminum die casting vendors. Prototype development, material selection advice, and design for manufacturability consulting are all included in custom design help. Faster product development cycles and design optimization prior to full production tooling investment are made possible by this flexibility.

What levels of quality can I anticipate from reliable vendors?

Reputable vendors have industry-specific certifications such as AS9100 for aerospace applications or TS 16949 for automotive applications, and they at least maintain ISO 9001 quality management systems. Material certifications, dimensional inspection reports, and process capability assessments are all examples of quality documentation. Coordinated measurement machine inspection capabilities and statistical process control are provided by advanced providers.

How can I confirm a supplier's capability before placing big orders?

Facility visits, sample analyses, reference checks, and pilot production runs should all be part of the capability verification process. Ask for samples that are comparable in complexity to your needs, and where required, carry out independent testing. Throughout the assessment process, assess problem-solving skills, communication efficacy, and technical support responsiveness.

Partner with Fudebao Technology for Superior Aluminum Die Casting Solutions

With precise components that go above and beyond industry requirements, Fudebao Technology is prepared to become your go-to source for aluminum die casting. Our skilled technical staff, sophisticated quality systems, and integrated production capabilities guarantee that your projects get the best possible solutions from conception to completion. Get in touch with hank.shen@fdbcasting.com right now to talk about your unique needs and see how our experience as an aluminum die casting manufacturer can improve the operation of your supply chain while cutting expenses and raising product quality.

References

American Foundry Society. "Aluminum Die Casting Process Guidelines and Quality Standards." AFS Technical Publication, 2023.

Society of Manufacturing Engineers. "Supplier Selection Criteria for Metal Casting Operations." SME Manufacturing Engineering Handbook, 2022.

International Organization for Standardization. "Quality Management Systems Requirements for Automotive Production and Relevant Service Parts Organizations." ISO/TS 16949:2016 Standard Documentation.

North American Die Casting Association. "Best Practices in Aluminum Die Casting Supplier Evaluation and Management." NADCA Technical Publication Series, 2023.

Materials Research Society. "Aluminum Alloy Selection and Properties for Industrial Applications." MRS Bulletin Manufacturing Technology Review, 2022.

Supply Chain Management Professional Association. "Strategic Supplier Assessment Methods for Metal Manufacturing Industries." SCMPA Industry Research Report, 2023.

YOU MAY LIKE

_1756346668222.webp)

_1756349794241.webp)

_1756352712247.webp)