One of the most accurate and efficient ways to make large quantities of complex metal parts is through aluminum die casting. This complete guide goes over the basic steps of the aluminum die casting process. It talks about important tolerances, how the process is used in the industry, and the best ways to do things that engineering managers and sourcing directors need to know. Mastering these ideas will help you make sure that your parts work well, don't cost too much, and are made reliably across a wide range of industrial uses, whether you're making housings for cars, parts for industrial equipment, or parts for spacecraft.

Understanding the Aluminum Die Casting Process

The first step in the high pressure die casting method is to melt aluminum metal in a controlled furnace. The temperature inside the furnace should be between 660°C and 750°C. During this step, careful temperature control stops rusting and makes sure that the material's qualities stay the same throughout the casting cycle.

As soon as the melted aluminum hits the right temperature, the die casting machine forces it into a carefully designed steel mold at a pressure of over 1,500 PSI. This filling speed changes based on the shape of the part, the width of the walls, and the surface finish that is needed. The fast cooling process, which is usually over in seconds, makes thick, nearly net-shaped parts that are very stable in their dimensions.

Modern die casting machines have complex control systems that keep an eye on the filling settings, the temperature of the mold, and the cooling processes. These automatic systems make sure that the same results are obtained every time and reduce flaws in the casting, like porosity, cold shuts, and flash. From injection to release, the whole process cycle usually takes between 30 and 120 seconds, which makes it perfect for situations where a lot of products need to be made.

Modern mold design includes many holes, complex cooling ducts, and ejection devices that make it easy to take out the part. With precision casting, makers can make parts with complicated shapes, thin walls, and built-in features that would need to be machined in multiple steps with standard methods.

Critical Tolerance Specifications and Quality Standards

Tolerances for die casting rely on a number of linked factors, such as the shape of the part, the metal used, and the complexity of the mold design. Most of the time, standard aluminum die casting can achieve linear limits of ±0.1mm to ±0.3mm. More advanced methods, when paired with secondary cutting operations, can reach ±0.05mm accuracy.

Wall width consistency in aluminum die casting is a key part of making sure that the standards are the same all the way through the component. Depending on the size and complexity of the casting, the minimum wall thickness that is suggested is between 1.5 mm and 3 mm. Different cooling rates can cause warping and changes in size, but uniform section thickness stops this from happening.

The quality of the surface finish is directly linked to the state of the cast, the injection settings, and the alloy's properties. Standard die casting surfaces have Ra values between 1.6 and 6.3 micrometers, which are good for most business uses. Surface treatments like shot blasting, anodizing, and powder finishing can make things look even better and make them less likely to rust.

Protocols for quality control include methods for measuring, testing, and visually inspecting things. Statistical process control methods keep an eye on important factors during production runs to make sure that the quality of the result is always the same. PPAP paperwork gives customers in the car and aircraft industries all the proof data they need to approve parts and keep working with suppliers.

Material Properties and Alloy Selection

Choosing the right aluminum metal has a big effect on how well the casting works, its mechanical qualities, and its fitness for use. Some well-known metals are A380, A383, and A413. Each has its own benefits for certain uses. The A380 has great flexibility and physical stability, which makes it perfect for making complicated thin-wall parts.

Thermal conductivity is an important trait for uses in energy and electricity. Aluminum naturally moves heat away from itself better than metal materials. Depending on the alloy makeup, its thermal conductivity ranges from 96 to 237 W/m·K. Because of this, aluminum casting parts are great for making motor housings, heat sinks, and electrical casings.

Optimizing the strength-to-weight ratio guides the choice of materials in aircraft and automobile uses. Die-cast aluminum parts usually have tensile strengths between 240 and 350 MPa and are only about a third as dense as steel parts of the same size. When the needs of the product call for higher levels of strength, heat treatment methods can improve mechanical qualities even more.

Different aluminum alloys used in aluminum die casting have different levels of corrosion resistance, with formulas that contain silicon giving better protection against external exposure. When you choose the right metal and treat the surface properly, it will last for a long time in tough settings like naval, automobile, and industrial ones.

Industrial Applications and Market Segments

The biggest market for lightweight metal casting is in the automotive industry, which includes engine parts, transmission housings, suspension frames, and structural elements. Modern cars and trucks have hundreds of die-cast metal parts that help them use less gas while still meeting safety standards.

Aluminum casting parts are used by companies that make industrial machinery for parts like pumps, compressors, engine housings, and heavy equipment. For these uses, the materials must have stable qualities, be the right size, and work reliably under constant working conditions. The precision casting method makes parts that meet strict spec standards and can be made in a variety of batch sizes.

Aluminum's good conductivity and resistance to rust make it useful in the electrical and energy sectors. Die-cast parts are used by companies that make power tools for motor housings, electrical casings, connecting bodies, and heat control systems. Aluminum's longevity and heat performance make it a great choice for renewable energy uses.

The aerospace and defense businesses need specific aluminum die casting skills that focus on lowering weight, increasing strength, and maintaining high quality standards. In these situations, complicated shapes, tight standards, and lots of paperwork for tracking are common. Coordinate measure tools and X-ray analysis are two advanced checking methods that are used to make sure that parts are complete and meet industry standards.

Design Considerations and Best Practices

To create a good aluminum die casting, you must first understand how the material flows and how it solidifies. Usually, draft angles between 0.5 and 3 degrees make it easier for parts to come out of the mold and extend its life. Using the draft correctly keeps the surface from getting damaged and cuts down on cycle time by letting you remove parts smoothly.

Spreading out the wall width evenly reduces heat stress and stops casting flaws. Large radius requirements allow sections to change gradually, which helps materials move smoothly and lowers noise during injection. Stress can build up in places where there are sharp points or rapid changes in thickness, which can cause cracks or porosity problems.

When molds are being made, undercut features need extra attention. Slide systems, lifts, and cores that can be collapsed make it possible to make complicated shapes while keeping the cost of the tools low. These traits, on the other hand, make designing die casting molds more difficult and could slow down production rates.

Mold surface preparation and upkeep procedures are affected by the required surface roughness. Polished surfaces have finishes that look like mirrors and are good for artistic uses. Textured surfaces, on the other hand, can hide small flaws and make it easier for coatings to stick. To make sure the mold is ready correctly, design teams should say what the surface needs to be like early on in the development process.

Quality Control and Defect Prevention

One of the most common quality problems in die casting is porosity, which is usually caused by trapped gases, poor ventilation, or high filling speeds. The right mold design includes exhaust systems and overflow wells that let gases that get stuck during filling escape.

When liquid metal fronts don't bond properly, they leave lines or weak spots in the finished part that can be seen. These are called cold shut flaws. Getting the injection speed, mold temperature, and gate design just right can help stop cold shut forming and keep the filling properties.

When there is too much injection pressure or worn mold parts, flash formation happens. Regular mold maintenance, setting up the machine correctly, and sticking to the suggested working parameters all help to lower the chance of flash and the number of secondary cutting operations that need to be done.

Statistical process control methods are used in dimensional variation tracking to find trends before they lead to parts that don't meet standards. Real-time tracking tools let workers know when parameters change in a way that could affect quality, so they can fix the problem right away.I don't know what to say.

Conclusion

As technology improves and processes are made more efficient, aluminum die casting keeps changing and providing more complex solutions in many different industries. Knowing the basics of the process, the range of tolerances that can be used, and the needs of the application lets you make smart choices about designing components and choosing a source. Modern die casting processes are very accurate and can make a lot of things quickly to meet the needs of a demanding market. For things to work, design teams need to work together with skilled casting suppliers who know how materials behave, how to make tools, and how to follow quality control rules. Aluminum die casting is still a crucial production technology that drives innovation and performance gains as businesses look for lightweight, long-lasting, and cost-effective solutions.

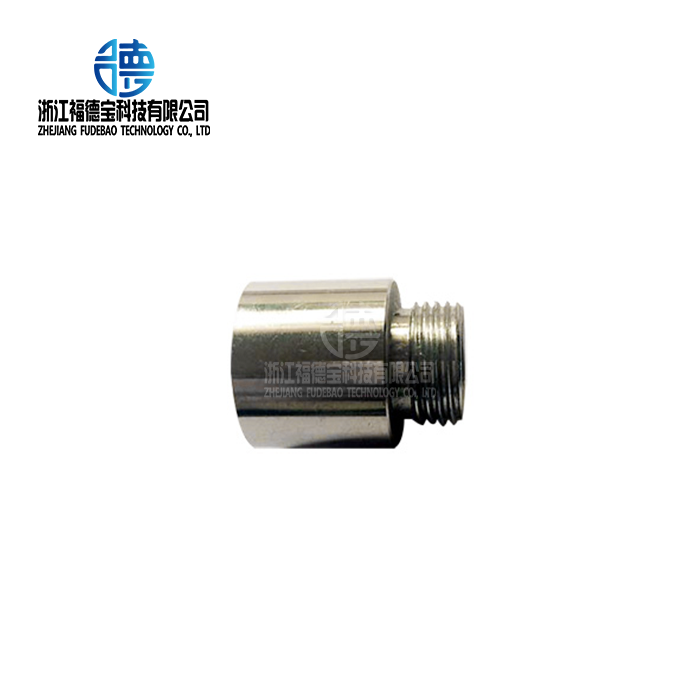

Partner with Fudebao Technology for Premium Aluminum Die Casting Solutions

Zhejiang Fudebao Technology blends advanced production skills with years of experience working in aircraft, automobile, and industrial settings. We offer a full range of aluminum die casting services, including creating molds, casting parts precisely, and finishing them so they meet the strictest requirements. As a reliable provider of aluminum die castings, we help with projects from the pilot stage all the way through high-volume production with accuracy of up to 0.05 mm. Ready to talk about your next project that uses aluminum die casting? You can email us at hank.shen@fdbcasting.com for technical help and quote support.

References

North American Die Casting Association. "Product Design for Die Casting." NADCA Publication, 2019.

Campbell, J. "Complete Casting Handbook: Metal Casting Processes, Metallurgy, Techniques and Design." Butterworth-Heinemann, 2015.

ASM International. "Casting: ASM Handbook Volume 15." ASM International Materials Park, 2008.

Vinarcik, E.J. "High Integrity Die Casting Processes." John Wiley & Sons, 2003.

Society of Automotive Engineers. "Aluminum Die Casting for Automotive Applications." SAE Technical Paper Series, 2020.

Beeley, P. "Foundry Technology." Newnes-Butterworth, 2001.

_1756349002499.webp)

_1756350092126.webp)

_1756352625880.webp)

_1756352712247.webp)

_1756361323684.webp)