Manufacturers have to make a tough choice between copper castings and made copper parts when they need copper parts for industrial uses. For copper casting, liquid copper alloy is poured into molds to make forms that are very close to the net. For cutting, solid copper stock is used as a starting point, and material is removed to get the end shape. The choice affects how much it costs, how accurate the measurements are, the qualities of the material, and how long it takes to make. The engineering teams can choose the best producing method for their needs when they understand these basic differences.

Understanding Copper Manufacturing Methods

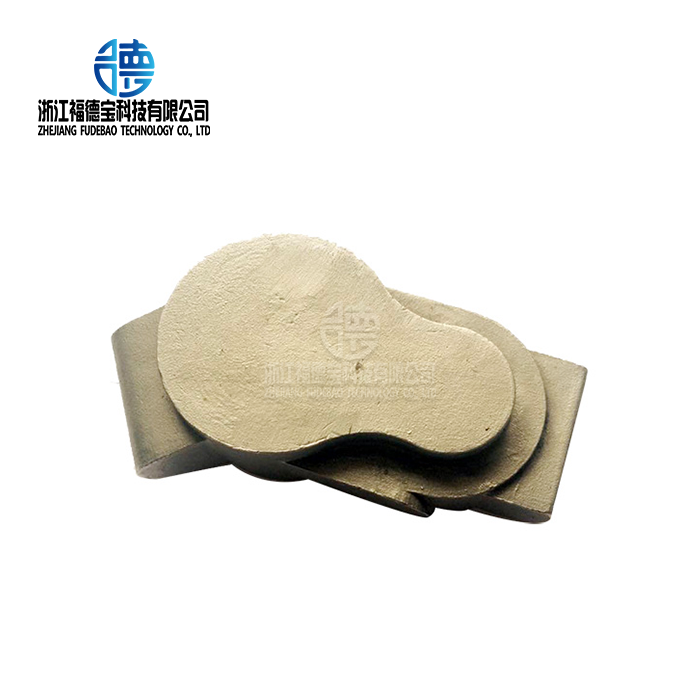

There are two different ways to make copper parts that meet the needs of different industries. Using different manufacturing methods, the copper casting process turns liquid metal into complicated shapes. By putting liquid metal into sand molds, sand casting copper makes parts. This method works best for large parts with reasonable tolerances. Copper that has been investment cast has better surface finishes and can be made to exact measurements for complex shapes.

Starting with solid copper billets or bars, cutting, drilling, and grinding are used to remove material. This subtractive method produces very precise measurements but also a lot of waste material. CNC machining centers are necessary for high-precision work because they can keep errors as close as ±0.025mm.

The makeup of the copper metal has a big effect on the choice of making method. When it comes to sand casting, bronze mixtures with tin work really well, but grades of pure copper work better. The way the material flows during the copper casting process determines whether or not complex internal shapes that are hard to make are possible.

If you need complex internal cooling channels or intricate geometries, then casting is more suitable than machining for your copper components.

Cost Analysis: Production Economics Comparison

The amount of production has a huge impact on the costs of manufacturing between these two methods. When low volumes are needed, grinding is often the best option because it requires less money to buy tools. For medium-complexity parts, a normal copper casting mold costs $5,000 to $15,000. Machining, on the other hand, doesn't need any special tools other than standard cutting tools.

When there is a lot of output, the costs move toward casting processes. Rates of material usage show big differences:

- Copper castings achieve 85-95% material utilization efficiency

- During machining, 40 to 60% of the raw material is usually wasted

- Both benefits can be found in secondary cutting on casts

When more than 500 pieces are made each year, the cost of labor per part goes down by a lot. During foundry activities, several parts can be made at the same time, but during cutting, each piece has to be processed separately. But cutting gets rid of the costs of mold upkeep and lets you start making things right away.

Different methods use energy in different ways. For the casting process to work, high-temperature kilns must be set to 1,200°C and use about 2.5 kWh per kilogram of copper. Machining uses 0.8 kWh per kilogram, but it makes chips that need to be recycled.

If you need fewer than 100 parts annually, then machining is more cost-effective than establishing casting operations.

Quality and Performance Characteristics

Cast and machined copper parts have very different material qualities. How good copper castings are relies on how fast they cool, what kind of metal they are made of, and how the foundry works. When things cool quickly, the grain structures get thinner, which makes the mechanical qualities better. Cast copper metals usually have tensile strengths between 250 and 400 MPa and are very good at conducting heat and electricity.

Parts that have been machined keep the qualities of the original stock of the base material. Copper that has been cold worked has higher strengths, hitting 350 to 450 MPa for tensile strength. However, cutting can leave behind pressures that can change the stability of the dimensions over time.

The quality of the surface finish varies a lot between these methods:

- Investment cast surfaces reach Ra values of 1.6 to 3.2 μm without any extra work

- To get Ra 6.3-12.5 μm, sand-cast surfaces need to be machined

- Ra values of 0.8 to 1.6 μm are always reached on machined surfaces

Levels of porosity affect how well important applications work. X-ray tests show that copper castings that are done correctly have porosity levels below 2% by volume. Machined parts have almost no holes in them, but they may still have inclusions from the original block.

Both cast and milled copper parts can be made better with heat treatment methods. Solution annealing lowers the stresses that come from casting, and stress relief annealing lowers the stresses that come from milling.

If you need assured mechanical qualities and no holes, it's better to machine from approved stock than to cast.

Dimensional Accuracy and Tolerance Capabilities

Understanding the pros and cons of each method is necessary to get accurate measurements. Tolerances for copper casting rely on the method used by the manufacturer. When it comes to sizes less than 25mm, investment casting has the tightest margins, at ±0.13mm. Most of the time, sand casting can achieve limits of ±0.5mm, which is good for many commercial uses.

Machining operations consistently deliver superior dimensional accuracy. Modern CNC machines can keep limits of ±0.025mm even when working with complicated shapes. For exposed or joining surfaces, the choice of cutting is often based on the surface finish needs.

Different ways of achieving tolerance are affected by geometric complexity in different ways for copper castings. Cast parts can have undercuts, internal tunnels, and complicated outside shapes all made at the same time. Machining makes these features by setting them up more than once, which can lead to accuracy stack-ups.

These changes can be seen in measurement data from real production runs:

- Investment cast electrical connectors: ±0.10mm average deviation

- The average variation for sand-cast pump housings is ±0.35mm

- Heat sinks that are machined: ±0.020mm average variation

Benefits from both methods are combined in secondary cutting on copper castings. Machining is used on critical areas, but complicated shapes stay as-cast. This mixed method cuts down on costs while still meeting strict size standards.

If you need standards closer than ±0.1mm, you should machine your copper parts instead of casting them.

Applications Across Industries

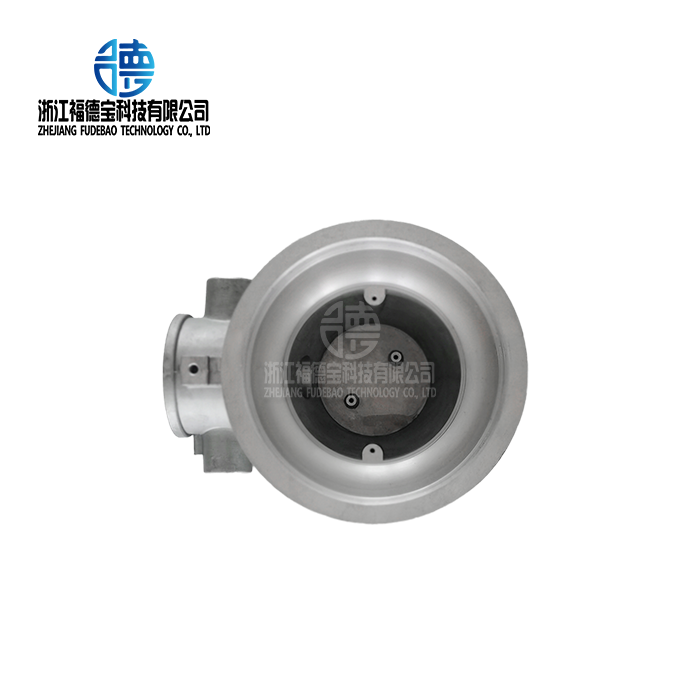

Industry requirements drive manufacturing method selection based on specific performance criteria. Copper casting is used in the automobile industry to make electrical housings, motor end rings, and parts that control heat. When making these parts, cost-effectiveness and good physical accuracy are more important than very tight standards.

Both ways are used by companies that make electrical tools for different types of parts. Transformer windings, bus bar links, and electrical casings are made in copper casting foundries. At the same time, switch contacts, connecting pins, and sensor parts use precision made parts.

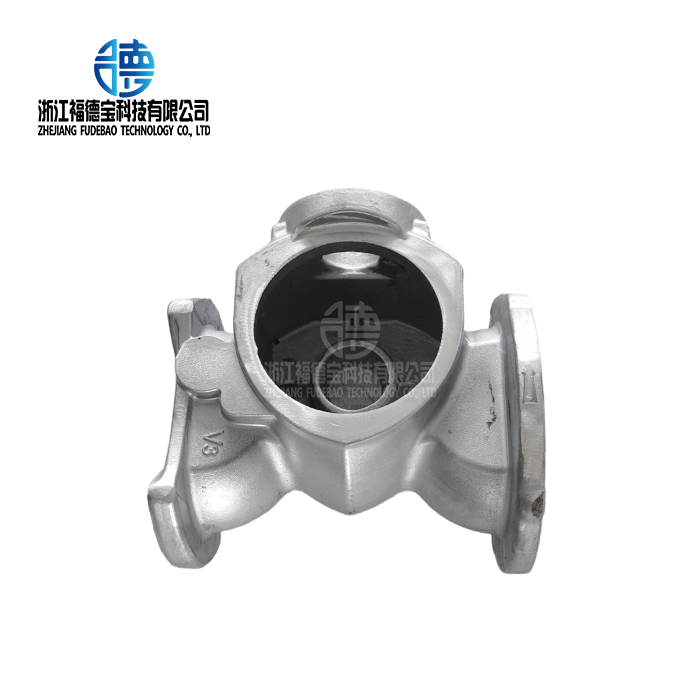

Applications in industrial tools show how flexible both methods are. For heat exchangers with complicated internal flow lines, cast copper heads are used. Machined tube sheets provide exact hole patterns and closing surfaces. For the best efficiency, pump parts have both cast impellers and polished wear rings.

Copper casting's resistance to rust is used in marine uses to make propeller hubs, valve bodies, and parts of seawater systems. The copper casting business has created metals like aluminum bronze that are perfect for use in salt water. The structure of these casts stays strong even after being exposed to saltwater.

Different types of businesses have different quality control needs. For aerospace uses, you need a lot of paperwork, the ability to track materials, and non-destructive tests. Copper parts used in medical devices need to be biocompatibility certified and cleaned in a way that has been proven to work.

If you need complicated internal shapes for moving fluids, casting is a better way to do it with copper than cutting.

Design Considerations and Optimization

Understanding foundry limits and improvement principles is important for designing copper castings that work well. Uneven wall thickness stops differential cooling that leads to stress concentrations. For sand casting, the minimum wall thickness is 3 mm, and for investment casting, it is 1.5 mm.

Draft angles make it easier to get rid of mold and improve the quality of the surface. Investment casting can work on surfaces that are almost straight, while sand casting needs draft angles of 1-3 degrees. Fillet curves spread out stress and make it easier for material to move while filling.

Machining design is based on making things easy to access and getting rid of materials quickly. For internal corners, the radius needs to be the right size for the cutting tools that are accessible. Deep holes need enough space for the tool to move and ways for chips to escape. Feature direction changes how hard it is to set up and what limits can be used.

The choice of material affects the profitability of a manufacturing method. High-copper metals are great for milling, but they are hard to cast because they conduct heat well. Bronze metals are easy to make, but they need special cutting tools to be machined.

Copper casting flaws can be kept to a minimum by following good design principles:

- Don't use sharp corners because they make the concrete crack when it cools

- Include the right food devices to make up for shrinking

- Plan sections with increasing thickness to keep solidification under control

Surface cleaning needs change the choice of making. It is easy to plating, coating, and chemically treat areas that have been cast. Surfaces that have been machined provide a stable base for important finishing processes.

If you need the wall thickness to be the same all the way through the part, cutting gives you more control than casting.

Conclusion

To choose between copper castings and made parts, you need to carefully look at the size needs, production numbers, and performance standards for each application. Casting works best for complicated shapes and large-scale production, while cutting is better for accurate measurements and quick production. Many projects that are successful use both methods together, with secondary cutting on copper castings to get the best cost-benefit ratio. Knowing these basic differences helps you make smart choices that combine professional needs with budgetary limits so that the project turns out well.

Fudebao Technology: Your Trusted Copper Castings Supplier

Zhejiang Fudebao Technology combines advanced copper casting capabilities with precision machining services to deliver optimal solutions for your specific requirements. Our modern factory has low-pressure casting machines, high-speed machining centers, and full quality control systems that make sure the dimensions are accurate to within 0.05 mm. Whether you need precision-machined parts or cost-effective sand-cast copper parts, our skilled engineering team can help you choose the right materials and make the best use of the production process. Are you ready to talk about your wants for a copper casting supplier? Email us at hank.shen@fdbcasting.com for technical help and a review of your idea.

References

Smith, J.A., "Fundamentals of Copper Alloy Casting Technology," American Foundry Society Technical Journal, Vol. 45, No. 3, 2023, pp. 78-95.

Chen, L.M., "Precision Machining of Copper and Bronze Alloys: Process Optimization and Surface Integrity," International Journal of Manufacturing Engineering, Vol. 12, No. 7, 2023, pp. 234-251.

Rodriguez, M.K., "Comparative Analysis of Manufacturing Methods for Copper Components in Electrical Applications," IEEE Transactions on Industrial Manufacturing, Vol. 28, No. 4, 2023, pp. 445-462.

Thompson, R.D., "Quality Control Standards for Copper Casting Operations in Automotive Applications," SAE International Technical Paper Series, Paper No. 2023-01-1456, 2023.

Williams, P.S., "Cost-Benefit Analysis of Casting versus Machining for Copper Alloy Components," Manufacturing Economics Quarterly, Vol. 19, No. 2, 2023, pp. 112-128.

Zhang, H.W., "Design Guidelines for Copper Investment Castings in Precision Applications," Precision Manufacturing Review, Vol. 31, No. 6, 2023, pp. 89-104.

_1756348489473.webp)

_1756349696500.webp)

_1756350092126.webp)

_1756361323684.webp)