Copper casts are one of the most flexible and effective ways to make things in many different fields. Copper's great heat transfer, electrical qualities, and resistance to rust are used in these specific parts to solve important technical problems. Copper castings provide performance that is unmatched by any other material, from heat exchanges for cars to blades for ships. These precision-engineered parts are used by industries all over the world in situations where they need to be very durable, conduct electricity well, and not break down in tough environments. Knowing the different uses of these metal parts helps engineers and buying workers choose the right materials and work with suppliers in the best way possible.

Electrical and Power Generation Applications

Copper metal casts are very important to the electrical business because they are great at conducting electricity and keeping heat in check. These parts are used a lot in power plants for things like motor parts, transformer housings, and electrical switches. The sand casting copper method makes strong electrical casings that keep sensitive equipment safe from the environment and make sure that heat moves away properly.

Wind mills use bronze casts in their electrical systems and bearing sets as part of green energy systems. These parts must be able to handle steady shaking and changes in temperature while still working electrically. Copper is made into transformer housings and electrical link systems for solar power setups. Corrosion resistance is very important for long-term dependability.

An important thing that electrical engineers like about current copper casting methods is that they produce uniform quality. These parts are great for custom electrical housings and specialized connection systems because they can be made with complicated shapes and tight standards. Brass casts are used in many moving parts and safety equipment that power distribution networks count on to work effectively for decades.

Marine and Shipbuilding Industries

Maritime uses put metal parts through some of the toughest conditions, so copper casting metallurgy is an important part of naval engineering. Due to their high resistance to rust in saltwater, bronze casts are commonly used by shipbuilders for blades, rudders, and seawater pumps. Centrifugal casting of copper makes blades that are thick and regular, which means they work better and last longer.

Copper's ability to conduct heat well, as found in copper castings, makes parts of marine engines work better. Different types of copper metal casts are used in heat exchangers, cooling system parts, and engine blocks to effectively handle thermal loads. For these uses, you need materials that don't corrode when they come into contact with electricity and keep their shape under dynamic loading.

Specialized brass casts are used to make valve bodies, pipe fittings, and pump parts for naval boats and offshore sites. The quality control methods for copper casting make sure that these important parts meet the strict standards set by the Marine Classification Society. With investment casting copper methods, precise parts are made for communication and guidance systems that can't be compromised on reliability.

Industrial Machinery and Heavy Equipment

For heavy-duty machinery parts, factories all over the world count on copper casting uses. Copper's strength and resistance to rust make it useful for pump housings, compressor parts, and hydraulic system parts. Manufacturers can make complicated internal pathways and cooling channels that improve the performance of equipment using the copper casting method.

Mining equipment works in very difficult conditions, and when a part breaks, it can cause a lot of downtime and safety risks. Bronze casts are strong enough for rollers on conveyors, parts for crushers, and material handling equipment. These parts have to be able to withstand harsh wear and keep their shape when they're under a lot of weight.

Industrial heat exchanges are another important use where knowing how to make copper castings is important. These parts effectively move heat energy while also being resistant to rust from process fluids. These options are better than manufactured ones because they can have complex internal shapes thanks to special casting methods.

Automotive and Transportation Components

Multiple copper metal casts are used in many parts of modern cars, mostly in electrical and temperature control systems. Heat exchangers in cars, like radiators and HVAC parts, use copper's thermal conductivity to keep the right temperatures for running. The level of accuracy that can be reached through controlled copper casting methods is high enough for car uses.

Copper casting is being used more and more by companies that make electric vehicles for motor housings, battery temperature control systems, and charge infrastructure parts. For these uses, you need materials that are good at conducting electricity and getting rid of heat well. For car parts, the copper casting surface finish requirements are often stricter than normal industry standards.

Heavy-duty cars' brake system parts are made of special brass casts that can handle high temperatures and keep their contact properties. To make sure they always work right, these safety-critical copper casting parts go through strict quality control steps. These materials are also used in railway uses for brake parts and electricity collection devices.

Architectural and Construction Applications

Copper castings are popular in the building business because they look good, last a long time, and require little upkeep. Copper's natural patina formation and resistance to rust make it a good material for architectural tools, artistic elements, and building system parts. Using techniques for investment casting copper, you can make detailed patterns that are both useful and beautiful.

Brass casts are used in plumbing systems for valve bodies, fittings, and fastening parts that need to work without leaks for decades. Because copper is a strong metal, these parts can handle changes in water flow and temperature changing. Copper-based products are often required by modern green building standards because they can be recycled and last a long time.

Bronze casts are used in sprinkler heads, valve units, and pump parts that are used in fire protection systems because they need to be reliable. Materials that keep their qualities in disaster situations and don't rust in standing water are needed for these uses. The heat treatment methods used in copper casting make the mechanical qualities better for these important uses.

Aerospace and Defense Technologies

Copper casting applications need to be very reliable and work very well in aerospace applications. Specialized copper metals are used in aircraft electrical systems, radar parts, and communication gear to meet strict weight and performance standards. Advanced copper casting methods make it possible to make shapes with complicated designs while keeping limits very close.

For defense purposes, materials need to be able to regularly work in harsh circumstances and still meet security and tracking standards. Manufacturers of copper castings must show that they have complete quality systems and methods for certifying materials. Copper's ability to shield electromagnetic waves and control temperature is important for electronic defense systems and transmission gear.

In temperature control systems and electrical housings where failure is not an option, satellite and space research technologies use copper castings. For these uses, copper casting design and production skills are pushed to their limits. Space's vacuum and radiation make it necessary for things to be very stable and have known behavior patterns.

Oil and Gas Industry Applications

Throughout their buildings, oil production and processing companies use copper casting uses a lot. Components of pumps, valve bodies, and heat exchangers must be able to withstand toxic process fluids while still remaining structurally sound. Specialized metals have been made by the copper casting business to meet the specific needs of petroleum handling settings.

Bronze casts are used in seawater handling systems and fire safety tools on offshore drilling sites, where being exposed to saltwater makes conditions difficult. These parts have to work reliably in faraway areas where repair workers can't easily get to them. Goals for environmental responsibility in the energy field are also in line with the reusing qualities of copper casting.

Brass casts are used to make metering tools, pressure regulators, and safety systems that are used in pipelines and distribution networks. For these uses, the materials need to be able to keep their qualities over a wide range of temperatures and not crack from stress rust. If you use the right copper casting metals, these options will last a long time and won't cost too much for infrastructure uses.

Conclusion

Copper castings play a crucial role in contemporary manufacturing and infrastructure thanks to their wide range of uses. These flexible parts are great for electrical systems that need to be very conductive and marine settings that need to be very resistant to rust. They solve technical problems that other materials can't handle well. Copper casting techniques and alloys will continue to improve, which means that these materials will be important for future technology progress. Knowing the exact uses and benefits helps engineers and buying workers make smart choices that improve projects' performance, dependability, and long-term value.

FAQs

Why are copper castings better than other types of metal casting?

Copper casts have special benefits, such as fantastic heat and electrical conductivity, natural antibacterial qualities, and great resistance to rust. Because of these qualities, they are perfect for uses that need to get rid of heat, work well with electricity, or last a long time in difficult conditions. The material is very easy to work with and can also be precisely finished.

What is the best way to choose the right copper metal for my job?

The alloy you choose will depend on its performance needs, such as its strength, conductivity, resistance to rust, and the climate in which it will be used. Bronze metals are great for use in boats, while brass mixtures are great for use in plumbing and decorations. Based on your individual working conditions and performance requirements, our research team can suggest the best metal combinations for you.

What quality standards should I look for in companies that make copper castings?

Professional companies that make copper castings should give full certifications for the materials, reports on the dimensions of the castings, and process paperwork. Find providers that are ISO certified, can do advanced metallurgy tests, and have worked in your business before. Chemical research, mechanical tests, and non-destructive examination methods that are right for your purpose should all be part of quality control.

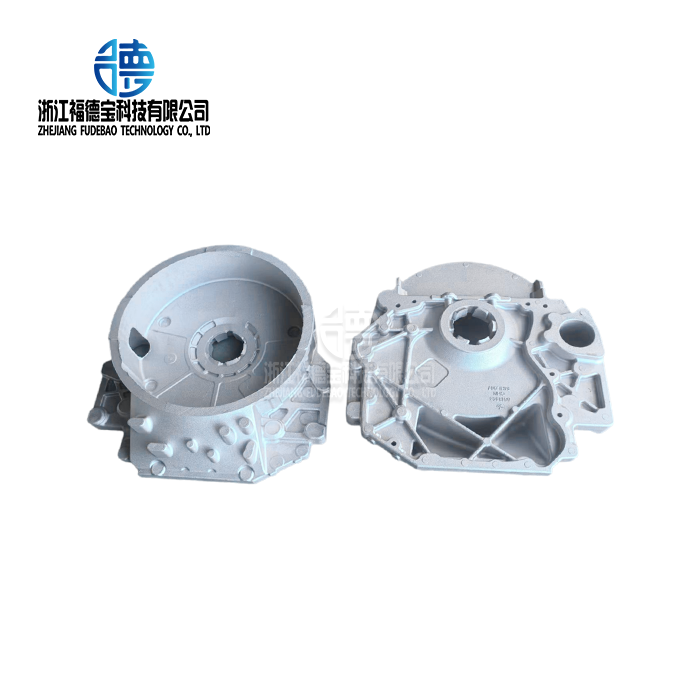

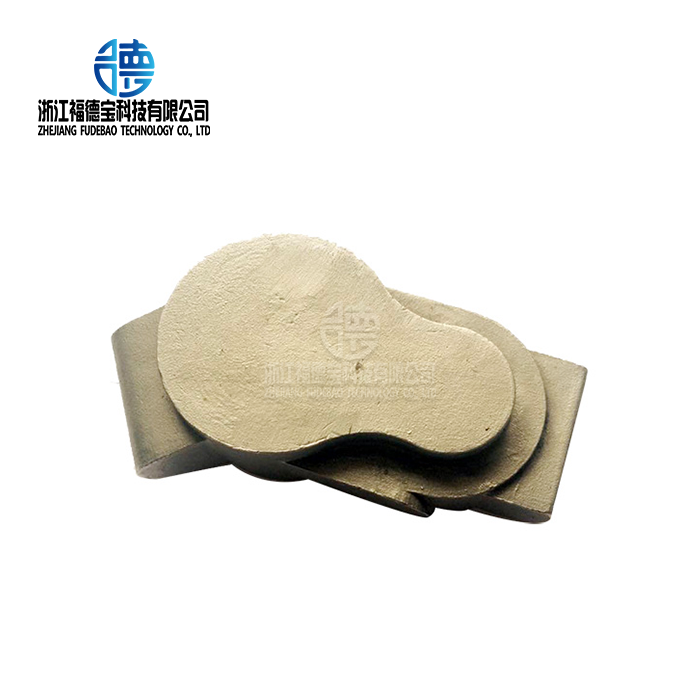

Choose Fudebao Technology as Your Trusted Copper Castings Supplier

Zhejiang Fudebao Technology makes precision-engineered copper casting solutions that meet the strict needs of businesses around the world. Our high-tech casting facilities and quality control systems make sure that the dimensions are always correct and the material has great features. Our expert team can help you with everything from planning to delivery, whether you need complicated parts for cars or unique solutions for boats. Get in touch with us at hank.shen@fdbcasting.com to talk about your unique needs and find out why top makers choose Fudebao Technology for their most important parts.

References

Davis, J.R. "Copper and Copper Alloys: ASM Specialty Handbook." ASM International, Materials Park, Ohio, 2001.

Campbell, J. "Complete Casting Handbook: Metal Casting Processes, Metallurgy, Techniques and Design." Butterworth-Heinemann, Oxford, 2015.

Beeley, P.R. "Foundry Technology." Butterworth-Heinemann, Oxford, 2001.

American Foundry Society. "Casting Design Handbook: Copper-Base Alloys." American Foundry Society, Schaumburg, Illinois, 1995.

Brown, J.R. "Foseco Foundryman's Handbook: Facts, Figures and Formulae." Butterworth-Heinemann, Oxford, 2000.

Copper Development Association. "Standards Handbook: Cast Copper Alloy Products." Copper Development Association, New York, 2018.

_1756348489473.webp)

_1756349071334.webp)