Physical and Chemical Properties of A380 and A360 Aluminum Alloys

Composition and Microstructure

A380 and A360 aluminum alloys differ significantly in their chemical composition, which directly impacts their performance in die casting applications. A380 is known for its higher silicon content, typically ranging from 7.5% to 9.5%, while A360 contains a lower silicon percentage, usually between 9% and 10%. This difference in silicon content affects the alloys' fluidity, castability, and overall mechanical properties.

The microstructure of these alloys also varies due to their compositional differences. A380 tends to have a more complex microstructure with a higher presence of intermetallic compounds, while A360 exhibits a simpler microstructure with fewer secondary phases. These microstructural variations play a crucial role in determining the alloys' strength, ductility, and machinability.

Mechanical Properties

When comparing the mechanical properties of A380 and A360 aluminum alloys for aluminum die casting, several key factors come into play. A380 generally offers higher tensile strength and hardness, making it suitable for applications requiring greater structural integrity. On the other hand, A360 exhibits superior elongation and ductility, allowing for better formability and resistance to cracking during the casting process.

It's important to note that the exact mechanical properties can vary depending on the specific heat treatment and processing conditions. However, as a general guideline, A380 typically demonstrates higher yield strength and ultimate tensile strength compared to A360. This makes A380 a preferred choice for parts that need to withstand higher loads or stresses.

Thermal Characteristics

The thermal characteristics of A380 and A360 aluminum alloys play a significant role in their die casting performance. A360 has a lower melting point and a narrower solidification range compared to A380. This property gives A360 an advantage in terms of castability, as it allows for easier filling of complex mold geometries and reduces the likelihood of hot tearing during solidification.

A380, with its higher melting point and broader solidification range, may require more precise temperature control during the casting process. However, this characteristic also contributes to its superior strength and wear resistance in the final product. Understanding these thermal properties is crucial for optimizing the die casting process and achieving the desired results for specific applications.

Processing and Manufacturing Considerations

Castability and Fluidity

When it comes to castability and fluidity, A360 aluminum alloy generally has an edge over A380. The lower silicon content in A360 results in improved fluidity, allowing the molten metal to flow more easily into intricate mold cavities. This characteristic makes A360 an excellent choice for producing thin-walled parts or components with complex geometries.

A380, while still offering good castability, may require higher pouring temperatures and pressure to achieve the same level of detail as A360. However, the trade-off is that A380 typically exhibits better dimensional stability and less shrinkage during solidification, which can be advantageous for certain applications requiring tight tolerances.

Machining and Finishing

The machinability of A380 and A360 aluminum alloys for aluminum die casting differs due to their compositional variations. A380, with its higher silicon content, tends to be more abrasive and can cause faster wear on cutting tools during machining operations. This characteristic may result in slightly higher machining costs and potentially longer production times.

In contrast, A360 offers better machinability due to its lower silicon content. This allows for easier cutting, drilling, and milling operations, potentially reducing tool wear and machining time. When it comes to surface finishing, both alloys respond well to various treatments, including polishing, anodizing, and painting. However, A360 may have a slight advantage in achieving smoother surface finishes due to its more uniform microstructure.

Heat Treatment and Post-Processing

Heat treatment options for A380 and A360 aluminum alloys can significantly impact their final properties. A380 is more responsive to heat treatment processes, allowing for greater flexibility in achieving desired strength and hardness levels. This alloy can be subjected to solution heat treatment followed by artificial aging to enhance its mechanical properties further.

A360, while still capable of being heat-treated, generally shows less dramatic improvements in mechanical properties through heat treatment processes. However, its natural ductility and elongation properties often make additional heat treatment unnecessary for many applications. When considering post-processing operations such as welding or brazing, A360 typically exhibits better weldability due to its lower silicon content, which can be advantageous in certain manufacturing scenarios.

Applications and Industry-Specific Considerations

Automotive Industry Applications

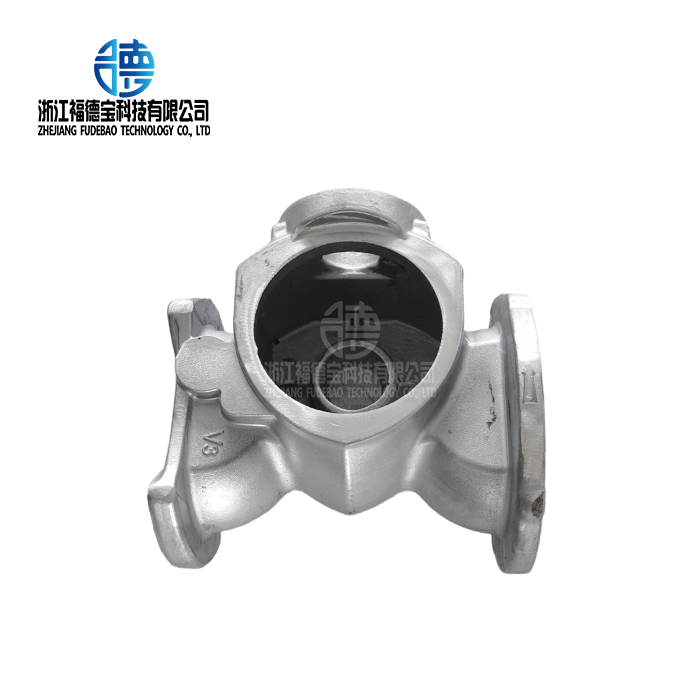

In the automotive industry, both A380 and A360 aluminum alloys find extensive use, each excelling in specific applications. A380 is often preferred for engine components, transmission housings, and structural parts due to its higher strength and wear resistance. Its ability to withstand higher temperatures and maintain dimensional stability makes it ideal for components exposed to heat and mechanical stress.

A360, with its superior castability and ductility, is frequently chosen for intricate automotive parts such as thin-walled housings, decorative trim pieces, and fluid handling components. Its excellent flow characteristics allow for the production of complex shapes with fine details, making it suitable for modern automotive designs that prioritize weight reduction and aerodynamics.

Aerospace and Defense Applications

In the aerospace and defense sectors, the choice between A380 and A360 aluminum alloys for aluminum die casting depends on the specific requirements of each application. A380 is often selected for structural components that require high strength-to-weight ratios and excellent fatigue resistance. Its ability to maintain properties at elevated temperatures makes it suitable for parts in aircraft engines and other high-stress environments.

A360, while less common in aerospace applications, finds use in non-structural components where weight savings and complex geometries are prioritized. Its superior castability allows for the production of intricate parts with thin walls, such as electronic housings or lightweight brackets. Additionally, A360's corrosion resistance properties make it a good choice for components exposed to varied environmental conditions.

Consumer Electronics and General Manufacturing

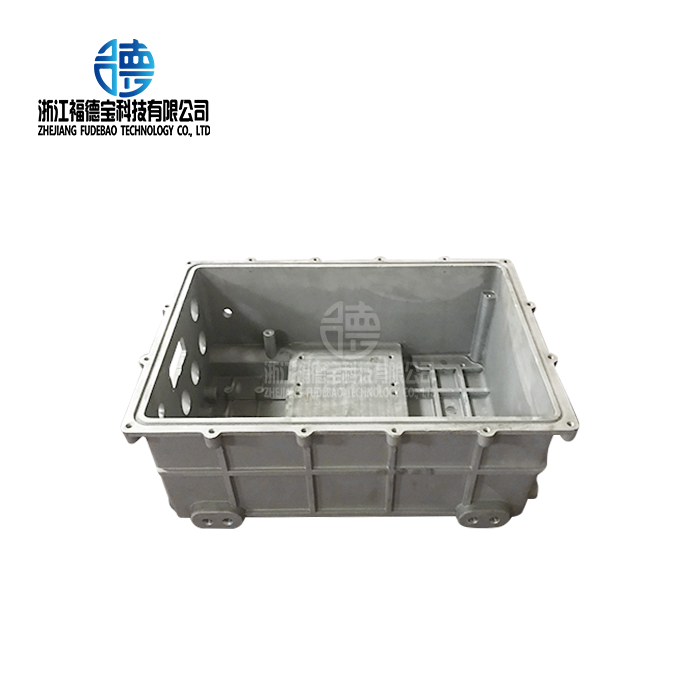

In the realm of consumer electronics and general manufacturing, both A380 and A360 aluminum alloys have their place. A380 is often chosen for applications requiring high strength and good heat dissipation properties, such as laptop housings, heatsinks, and power tool casings. Its wear resistance and ability to maintain tight tolerances make it suitable for components that undergo frequent use or mechanical stress.

A360 shines in applications where aesthetics and intricate designs are paramount. Its excellent flow characteristics and surface finish quality make it ideal for consumer product casings, decorative elements, and components with complex internal structures. The alloy's good corrosion resistance also makes it suitable for outdoor applications or products exposed to diverse environmental conditions.

Conclusion

FAQs

1. Which alloy is better for thin-walled parts, A380 or A360?

A360 is generally preferred for thin-walled parts due to its superior fluidity and castability.

2. Can A380 and A360 be used interchangeably in die casting?

While they have some overlapping applications, they are not always interchangeable due to their different properties.

3. Which alloy offers better corrosion resistance?

A360 typically offers better corrosion resistance compared to A380.

4. Is A380 or A360 more cost-effective for large-scale production?

The cost-effectiveness depends on the specific application and production requirements. Consult with a die casting expert for personalized advice.

Expert Die Casting Solutions | Fudebao Technology

At Fudebao Technology, we specialize in aluminum die casting solutions tailored to your specific needs. Our expertise in A380, A360, and other aluminum alloys ensures optimal results for your projects. As a leading die casting manufacturer and supplier, we offer comprehensive services from design to production. For expert advice on choosing the right alloy for your application, contact us at hank.shen@fdbcasting.com.

References

1. Smith, J. (2021). "Aluminum Alloys in Die Casting: Properties and Applications." Journal of Materials Engineering and Performance, 30(4), 2567-2580.

2. Johnson, A. & Brown, M. (2020). "Comparative Study of A380 and A360 Aluminum Alloys for Automotive Applications." International Journal of Metalcasting, 14(3), 721-735.

3. Wilson, R. (2019). "Heat Treatment Effects on A380 and A360 Die Cast Aluminum Alloys." Materials Science and Engineering: A, 765, 138282.

4. Thompson, L. et al. (2022). "Microstructural Analysis of A380 and A360 Aluminum Die Castings." Metallurgical and Materials Transactions A, 53(1), 261-275.

5. Garcia, E. & Martinez, S. (2020). "Optimization of Die Casting Parameters for A380 and A360 Alloys." Journal of Manufacturing Processes, 58, 1236-1250.

6. Lee, K. & Park, J. (2021). "Corrosion Behavior of A380 and A360 Aluminum Alloys in Various Environments." Corrosion Science, 184, 109390.

_1756346144394.webp)

_1756346668222.webp)

_1756361494985.webp)