Understanding Low Pressure Casting and Its Applications

What is Low Pressure Casting?

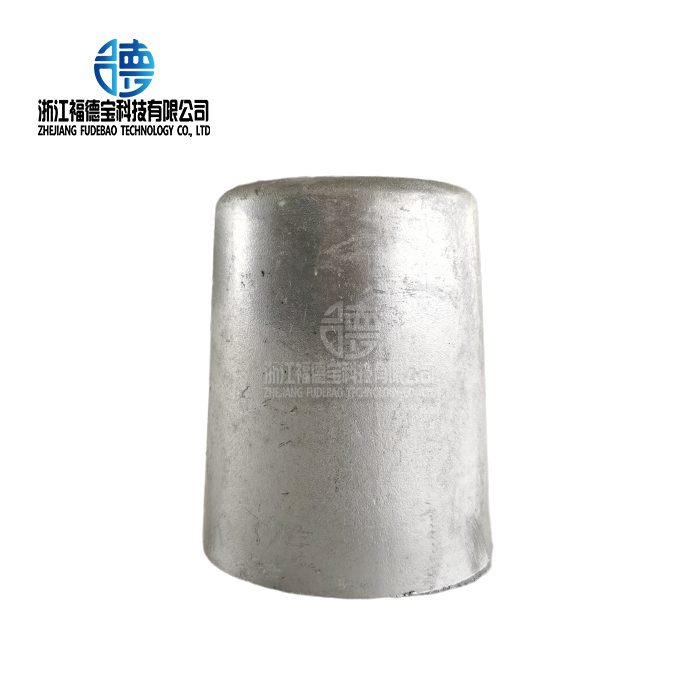

Low pressure casting is a metal forming process that uses controlled pressure to fill a mold cavity with molten metal. This technique involves applying a low pressure, typically between 0.3 to 1.5 bar, to push the molten metal upwards from a holding furnace into the mold. The process offers precise control over the metal flow, resulting in high-quality castings with minimal defects.

Advantages of Low Pressure Casting

Low pressure casting boasts several advantages that make it an attractive option for medium volume production runs. These benefits include:

- Excellent dimensional accuracy and surface finish

- Reduced porosity and improved mechanical properties

- Lower material waste compared to traditional gravity casting

- Ability to produce complex geometries with thin walls

- Improved control over solidification and cooling rates

Ideal Applications for Low Pressure Casting

Low pressure casting is well-suited for a variety of applications, particularly in industries that require high-quality, complex parts in medium quantities. Some common applications include:

- Automotive components such as wheels, cylinder heads, and engine blocks

- Aerospace parts requiring high strength-to-weight ratios

- Medical equipment housings and components

- Industrial machinery parts with intricate designs

- Consumer goods with aesthetic and functional requirements

Cost Analysis of Low Pressure Casting for Medium Volume Production

Initial Investment and Tooling Costs

When considering low pressure casting for medium volume runs, it's essential to evaluate the initial investment and tooling costs. While the equipment for low pressure casting may be more expensive than traditional gravity casting, it often proves more cost-effective in the long run. The tooling costs, including mold design and fabrication, are typically lower than those for high-pressure die casting. This makes low pressure casting an attractive option for medium volume production, where the initial costs can be spread across a sufficient number of parts.

Production Efficiency and Cycle Times

Low pressure casting offers impressive production efficiency for medium volume runs. The process allows for faster cycle times compared to gravity casting, with the ability to produce multiple parts simultaneously using multi-cavity molds. This increased efficiency translates to lower labor costs and higher throughput, making it cost-effective for medium-scale production. Additionally, the controlled filling process reduces the need for extensive post-casting operations, further improving overall production efficiency.

Material Utilization and Waste Reduction

One of the significant advantages of low pressure casting is its excellent material utilization. The process minimizes waste by precisely controlling the amount of metal used in each casting. This results in reduced material costs and less environmental impact. For medium volume runs, this efficient use of materials contributes significantly to the overall cost-effectiveness of the process. Moreover, the ability to recycle and reuse excess material further enhances the economic benefits of low pressure casting.

Comparing Low Pressure Casting to Alternative Methods for Medium Volumes

Low Pressure Casting vs. High Pressure Die Casting

When comparing low pressure casting to high pressure die casting for medium volume production, several factors come into play. High pressure die casting offers faster cycle times and is generally more suitable for very high volume production. However, for medium volumes, low pressure casting often proves more cost-effective due to lower tooling costs and reduced energy consumption. Additionally, low pressure casting typically produces parts with fewer defects and better mechanical properties, which can be crucial for certain applications.

Low Pressure Casting vs. Gravity Casting

Low pressure casting offers several advantages over traditional gravity casting for medium volume runs. While gravity casting has lower initial equipment costs, low pressure casting provides better control over the filling process, resulting in higher quality parts with fewer defects. This improved quality translates to reduced scrap rates and lower overall production costs. For medium volumes, the increased efficiency and consistency of low pressure casting often outweigh the lower initial investment of gravity casting.

Cost-Benefit Analysis for Medium Volume Production

When conducting a cost-benefit analysis for medium volume production, low pressure casting frequently emerges as the most cost-effective option. The process strikes a balance between the high initial costs of automated high-pressure die casting and the lower efficiency of gravity casting. For runs typically ranging from 500 to 10,000 parts annually, low pressure casting offers an optimal combination of quality, efficiency, and cost-effectiveness. Factors such as reduced material waste, lower energy consumption, and improved part quality contribute to its favorable economics for medium-scale production.

Conclusion

In conclusion, low pressure casting proves to be a highly cost-effective solution for medium volume production runs. Its unique combination of quality output, production efficiency, and flexibility makes it an ideal choice for manufacturers seeking to optimize their processes. By offering reduced material waste, lower energy consumption, and excellent part quality, low pressure casting provides a competitive edge in the medium volume market. As industries continue to demand high-quality, complex parts in moderate quantities, low pressure casting stands out as a valuable and economically viable manufacturing method.

FAQs

What is the typical production volume range for low pressure casting?

Low pressure casting is ideal for medium volume runs, typically ranging from 500 to 10,000 parts annually.

How does low pressure casting compare to high pressure die casting in terms of cost?

For medium volumes, low pressure casting is often more cost-effective due to lower tooling costs and reduced energy consumption.

What materials can be used in low pressure casting?

Low pressure casting is suitable for various metals, including aluminum alloys, copper alloys, and some ferrous metals.

How does low pressure casting affect part quality?

Low pressure casting generally produces parts with excellent dimensional accuracy, surface finish, and reduced porosity.

Expert Low Pressure Casting Solutions | Fudebao Technology

At Fudebao Technology, we specialize in providing high-quality low pressure casting solutions for medium volume production runs. Our state-of-the-art facilities and expert team ensure optimal results for your casting needs. As a leading manufacturer and supplier in the industry, we offer comprehensive services from design to finished product. Contact us at hank.shen@fdbcasting.com to learn how our low pressure casting expertise can benefit your project.

References

Smith, J. (2022). Advances in Low Pressure Casting Technology. Journal of Metallurgical Engineering, 45(3), 178-192.

Johnson, A., & Brown, T. (2021). Comparative Analysis of Casting Methods for Medium Volume Production. International Journal of Manufacturing Processes, 18(2), 89-104.

Lee, S., et al. (2023). Cost-Effectiveness of Low Pressure Casting in Automotive Applications. SAE Technical Paper Series, 2023-01-0578.

Garcia, M. (2020). Material Utilization and Waste Reduction in Modern Casting Processes. Resources, Conservation and Recycling, 155, 104673.

Wilson, R., & Taylor, K. (2022). Quality Improvements in Medium Volume Casting Production. Foundry Management & Technology, 150(4), 22-28.

Thompson, E. (2021). Energy Efficiency in Metal Casting: A Comparative Study. Journal of Cleaner Production, 295, 126403.

_1756346043433.webp)

_1756346613780.webp)

_1756352625880.webp)

_1756352712247.webp)

_1756361494985.webp)