This method of making big metal parts, called sand casting, is still the most popular because it is very flexible, cheap, and reliable in many different types of industries. This production method has been used for a long time and is very good at making complex, heavy parts while keeping the dimensions and purity of the material. Sand casting provides the strong performance required by procurement specialists and engineering managers for everything from engine blocks for cars to housings for industrial machines. In this in-depth analysis, we look at why this basic technology is still so important for modern manufacturing. This analysis can help decision-makers find the best production options for their large-scale component needs.

Understanding the Sand casting Process for Large Metal Components

The method of sand casting is one of the oldest and most reliable ways to make big metal parts that are used in many different industries. Over the past few decades, this flexible technique has changed a lot, adding new materials and more precise methods while keeping its main benefits of being flexible and inexpensive.

What is Sand casting and How Does it Work?

There are several carefully planned steps in the sand casting process that turn liquid metal into precisely made parts. Pattern making is the first step. Then, skilled workers use materials like metal, plastic, or wood to make exact copies of the part that is wanted. These models show how to make sand molds, which hold the liquid metal while it cools and hardens.

When making molds, special sand mixes are used, each chosen for its performance properties. Green sand, which is made up of silica sand, clay, and water, is still popular because it can be used again and again and doesn't cost much. Resin-bonded sand systems have a better surface finish and are more accurate in terms of size, which makes them perfect for precise work in the aircraft and automobile industries.

Controlling the temperature is very important during the whole process. Pouring temperatures for aluminum metals are usually between 1,300°F and 1,400°F, while temperatures for iron casts are higher than 2,500°F. Controlled cooling keeps thermal stress from happening and makes sure that the final part has the best mechanical qualities.

Key Materials and Design Considerations for Sand casting

Choosing the right materials has a big effect on how well large component casting processes go. Due to their high strength-to-weight ratios and resistance to rust, aluminum metals are popular choices for use in cars and spacecraft. Cast iron is great for big machinery parts because it doesn't wear down easily and doesn't cause vibrations. For challenging structural uses, steel castings are the best choice because they are stronger and tougher.

Design streamlining cuts down on common casting flaws while making it easier to make. The right draft angles make it easier to remove the pattern, and the smart placement of steps and gates makes sure that the mold is fully filled. Even wall thickness stops flaws caused by shrinking, and carefully placed cutting lines cut down on the need for grinding.

Some common flaws in casting are holes, sand inclusions, and differences in size. Careful process control, such as using the right degassing methods, making sure the sand is properly prepared, and keeping an eye on the temperature during the casting cycle, can help with these problems.

Advantages of Sand casting for Large-Scale Components

Large metal parts are made with sand casting because it has many strong benefits that make it the best choice for many businesses. These benefits go beyond just low costs; they also include design freedom, output scalability, and a wide range of materials that are hard for other casting methods to match.

Cost-Effectiveness and Flexibility Compared to Other Casting Processes

The cost benefits of sand casting are very high compared to other ways that have been studied. For big parts, die casting often needs an upfront investment of more than $100,000 in steel tools. Investment casting uses pricey clay shells and takes a long time to make. On the other hand, sand casting uses relatively cheap sand and simple tools, which lowers the original investment requirements.

Another big benefit is that production can be changed as needed. Sand models let you make changes to the design without having to buy new tools, which makes it possible to make quick prototypes and iterations on the design. This flexibility is very helpful for special parts or programs that need tech changes all the time.

When it comes to low to medium production runs, volume numbers favor sand casting. Die casting may be worth the money for high-volume production, but sand casting is still the more cost-effective way to make small batches or several thousand pieces a year.

Scalability and Adaptability for Complex and Heavy Components

Sand casting is great for making big, heavy parts that are hard to make with other methods. Parts that weigh several tons can be cast safely; the main thing that limits them is the foundry's handling tools, not the process itself. Cores and advanced casting methods make it easy to make parts with complex internal shapes, such as cooling tunnels with lots of small holes and lightweight empty sections.

Molds that can be used again and again and changed help with efficient production planning. Pattern changes let design changes happen without having to update all the tools, which speeds up development and saves money. This flexibility is especially helpful in fields like making big equipment, where part designs are always changing to meet new performance standards.

Sand casting Vs. Other Metal Casting Techniques: Making the Right Choice

To choose the best casting method, you need to carefully consider a number of factors, such as the size of the part, the amount of production, the required tolerances for dimensions, and the material needs. While sand casting has clear benefits for big parts, it also has some problems that need to be taken into account when making decisions.

Comparison of Sand casting, Investment Casting, Die Casting, and Permanent Mold Casting

Investment casting has a better surface finish and more accurate measurements, but it can't be used for all sizes and costs more for the materials. Investment casting isn't a good way to make parts that weigh more than 50 pounds, but sand casting is a common way to make parts that weigh several tons. Die casting is a great way to control the size of an object and make a lot of them quickly, but it costs a lot to buy the tools and can only be used with aluminum and zinc metals.

Permanent mold casting lets you control the size and finish of the part better than sand casting, and it can handle more output. Permanent models, on the other hand, make design changes less possible and take a lot of money to buy tools for, especially for large parts. With the right process control, sand casting can keep its better design flexibility and lower production costs while still having similar mechanical qualities.

Environmental factors are becoming more and more important in choosing a casting method. When compared to investment casting, which needs to get rid of clay shells, sand casting uses materials that can be recycled and makes less chemical waste. When it comes to energy use per pound of casting, sand casting usually wins because it's easier to do and requires less energy to prepare the material.

Emerging Technologies vs Traditional Sand casting

Metal 3D printing technologies get a lot of attention for making complicated parts, but they have a lot of problems when it comes to making big parts. Because of limitations on the size of the build room, long working times, and expensive materials, this method can only be used for small, complicated parts that are hard to cast in the usual way.

Shell molding has a better finish on the outside than green sand casting, but it costs more to make and is harder to do. When it comes to big parts, the benefits of shell molding rarely outweigh the extra cost and difficulty of handling compared to well-controlled sand casting.

Continuous improvement projects, such as automated molding systems, advanced sand recycling technologies, and high-tech process monitoring equipment, keep sand casting technologically relevant. These projects improve quality consistency while keeping the basic cost and flexibility advantages.

How to Choose the Best Sand casting Service and Supplier?

Picking the right supplier has a big effect on the success of a project, especially when it comes to making huge parts, where quality, speed, and expert help are very important. Professionals in buying can find partners who can meet high standards of performance by using thorough evaluation criteria.

Criteria for Selecting Reliable Sand casting Foundries and Manufacturers

Getting ISO 9001 approval shows that you are dedicated to quality management systems, which are necessary for producing big parts consistently through sand casting. Environmental certificates show that a company is using responsible production methods that are in line with its environmental goals. PPAP paperwork features are very important for car sellers who need to make sure the quality of their products is checked thoroughly.

Casting quality and output volume are directly related to the powers of the equipment. These days, foundries buy automatic casting lines, high-tech melting equipment, and high-tech quality control tools. Heat treatment facilities, the ability to machine parts, and surface treatment choices all work together to make supply chain management easier.

Superior sellers are different from basic casting companies because they offer engineering help. Technical advice during the planning part helps keep mistakes from being too expensive and makes the product easier to make. Simulation software for analyzing mold filling and modeling solidification shows advanced technical abilities that raise the success rate of quality on the first try.

Geographic Availability and Procurement Tips for Global Buyers

Regional seller networks can help with transportation costs, communication, and managing risks in the supply chain. Most of the time, domestic providers offer better expert help and faster reaction times for pressing needs. Global buying methods, on the other hand, may give you access to expert skills or lower costs that you can't get locally.

Transportation issues become very important when dealing with big parts, since the costs of shipping and handling have a big effect on the total cost of purchase. Suppliers who are close to major transportation hubs or who offer combined shipping services have an edge over their competitors because they can cut down on travel times and handling risks.

To make prices clear, more than just mentioned piece costs need to be looked at. The total cost analysis takes into account the costs of quality control, transportation, and the possible risks that come with delivery delays or quality problems. Reliable providers break down costs in a way that makes it easier to plan and budget for projects accurately.

Examples of how sand casting is used in the real world for large parts

Sand casting has been used for a long time in many different industries that need big, complicated metal parts. These real-life cases show how the technology can be used to solve common problems and show how flexible and reliable it is.

Industrial Examples of Sand casting in Automotive, Heavy Machinery, and Energy Sectors

Automotive engine blocks are a standard example of a sand casting application where the process can exactly meet the needs for size, complexity, and cost. Modern aluminum engine blocks have complicated cooling channels, mounting parts, and cylinder head preparations that need advanced coring methods. Production rates of tens of thousands to hundreds of thousands of units per year show that sand casting can be used in a wide range of market areas.

Large pump housings, engine parts, and structural elements for building tools are all heavy machinery uses. For these uses, the materials must have excellent mechanical qualities, be precisely measured, and have a surface that will last under tough working conditions. For modest output rates, sand casting is a cost-effective way to get the performance qualities that are needed.

Applications in the energy industry include parts for wind turbines, housings for generators, and gear for sending power. To make sure they work reliably in tough situations, these big, heavy parts need to be precisely measured and have excellent metallic qualities. To make sure products meet strict industry standards, quality control methods include checking all dimensions, testing without damaging the product, and checking the material's properties.

Lessons Learned and Best Practices from Industry Leaders

For big component casting processes to be successful, design engineers and casting experts need to work together early on. When design for manufacturability concepts are used during the early stages of development, changes that are needed during production don't have to be expensive. Pattern design optimization and smart placing of closing systems have a big effect on the quality and yield rates of castings.

Modern technologies for tracking processes allow for real-time quality control and failure prevention. Statistical process control methods, automatic sand quality control systems, and tracking the temperature during the casting cycle all help improve regularity while lowering the amount of scrap that is made. These advances in technology are paying off in a clear way: better quality and lower production costs.

Conclusion

Sand casting is still the best way to make big metal parts because it is cost-effective, allows for flexible design, and can be made on a large scale. This well-known technology keeps getting better by using new materials and making changes to the way it's done. It still has basic benefits that other casting methods can't match. Sand casting offers the adaptability and performance required to meet stringent industrial requirements successfully for procurement professionals and engineering managers looking for reliable, affordable solutions for big component manufacturing.

FAQs

Which metals work best for making big parts by sand casting?

Aluminum alloys are great for car and aircraft uses because they are strong for their weight and don't rust. Cast iron is better at keeping parts of heavy machinery from wearing out and dampening vibrations. Steel casts are very strong and can be used in construction uses. Copper metals are great for electrical and nautical uses that need to be able to carry electricity and prevent rust.

What problems do sand casting flaws do to big metal parts, and how can they be avoided?

Porosity, sand particles, and physical differences are all common flaws that can hurt the mechanical qualities and surface quality. To stop this from happening, you need to use the right degassing methods, prepare the sand well, control the cooling rates, and plan your gate system strategically. Testing for quality control and keeping an eye on the process on a regular basis ensures uniform results.

Is sand casting a good way to make small amounts of something at a low cost?

Yes, sand casting is very flexible and has lower equipment costs than die casting or investment casting. This makes it a very cost-effective way to make prototypes and small to medium-sized batches. Being able to change patterns and adapt to new designs without having to buy expensive new tools saves a lot of money when product designs are changing.

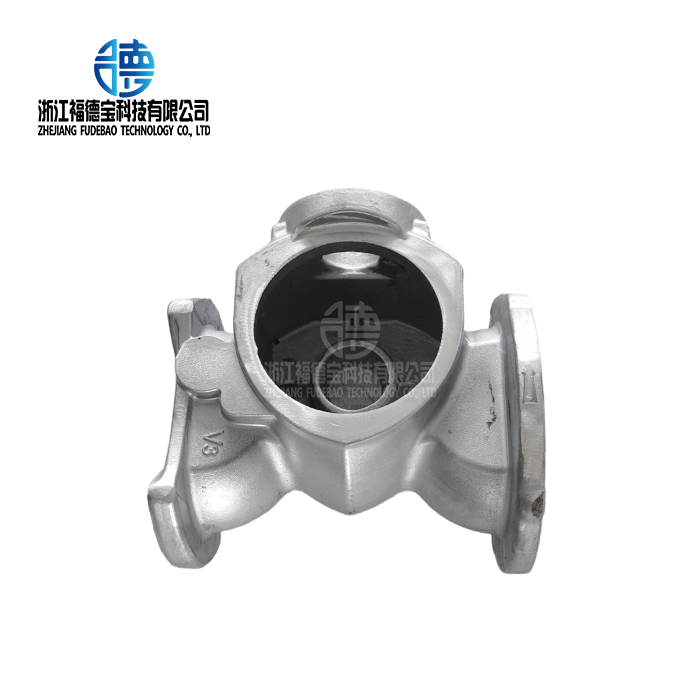

Fudebao Technology - Your Trusted Sand casting Supplier

Zhejiang Fudebao Technology Co., Ltd. is one of the biggest companies that makes sand castings. They make parts out of aluminum alloy, copper alloy, and stainless steel that are used in industries around the world. We can make a wide range of products for the aircraft, industrial equipment, automobile, and tool production industries. We can provide precision-engineered solutions that meet the strictest requirements.

Our modern building has high-speed machining centers, CNC lathes, low pressure casting machines, and die casting equipment, among other high-tech tools. This full framework serves the whole process of making something, from melting to casting to finishing and treating the surface. Tolerances of up to ±0.05mm are possible with our precision powers. This meets the strict needs of car precision parts, medical equipment housings, and aircraft components.

Quality control is still very important to us, and our ISO approval shows that we are dedicated to always doing our best. Our experienced engineering team provides full technical support from the initial design advice to the improvement of production, making sure that the project is completed successfully. Customers gain from our ability to offer everything in one place, which simplifies the supply chain while keeping high quality standards.

Work with a reputable sand casting company that is dedicated to new ideas, high quality, and customer satisfaction. Email us at hank.shen@fdbcasting.com to talk about your needs for big parts and find out how our knowledge can help you reach your manufacturing goals.

References

Campbell, J. (2015). "Complete Casting Handbook: Metal Casting Processes, Metallurgy, Techniques and Design." Butterworth-Heinemann Publishing.

Ravi, B. (2018). "Casting Simulation and Optimization: Fundamentals and Applications in Metal Casting." Springer International Publishing.

Brown, J.R. (2019). "Foseco Ferrous Foundryman's Handbook." Elsevier Science & Technology.

Davis, J.R. (2021). "ASM Specialty Handbook: Cast Irons." ASM International Materials Engineering.

Stefanescu, D.M. (2020). "Science and Engineering of Casting Solidification." Third Edition, Springer Publishing.

Beeley, P.R. (2017). "Foundry Technology: A Source Book of Information on the Theory and Practice of Foundry Work." Butterworth-Heinemann.

_1756346668222.webp)