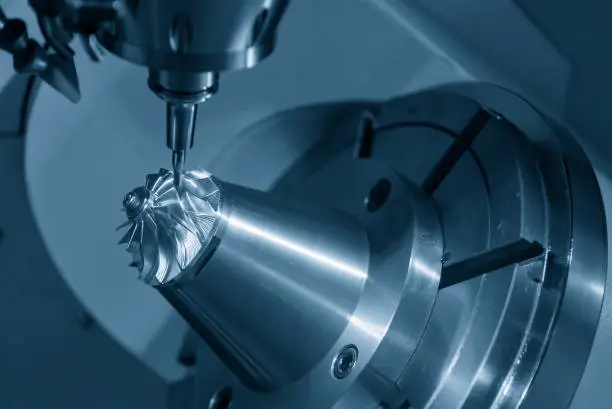

CNC machining makes aircraft and robots parts with unmatched accuracy by using advanced computer-controlled manufacturing methods that can reach limits of less than 0.001 inches. This advanced technology gets rid of human mistake and keeps the same level of accuracy in dimensions even when the geometry is complicated. This makes it necessary for mission-critical situations where safety and performance cannot be compromised. Because they are automatic, computer numerical control systems make sure that the same results are achieved every time. This helps the aircraft and robots industries meet their high quality standards. Modern CNC machining centers have more than one axis of movement, which lets them make complex parts that meet the high standards needed by robotics and flight systems.

Understanding CNC machining and Its Role in High-Precision Part Production

Computer numerical control technology carefully programs the movement of tools along multiple directions to turn digital patterns into real parts. Advanced software controls cutting processes on different materials in this way of making things, making sure that every part meets the exact specs without any changes. The process starts with detailed CAD models that show every measurement and finish need. These models are then turned into code that the cutting tools can read.

Advanced machining centers are very accurate, using servo motors and linear encoders to place cutting tools within microns of where they need to be. The closed-loop feedback systems keep an eye on the position of the tools all the time and make adjustments automatically if they move. This keeps the dimensions accurate during the whole cutting process. This level of control is very important for aircraft parts like turbine housings and robots parts like servo frames, where even small changes can hurt how well the system works.

Adding temperature adjustment systems makes things even more precise by taking into account how much things expand and contract when they are heated up during long cutting processes. These systems keep an eye on the temperature of the machine and change the settings of the tools automatically to fix any changes in size that happen because of the heat. This feature makes sure that the quality of the part stays the same no matter the environment or the length of time it takes to make. It meets the durability needs of both aircraft and robotics uses.

Core Factors That Enable High Precision in CNC machining

To get the very high levels of accuracy needed for aircraft and robots manufacturing, a number of important factors must work together. When engineers and buying teams choose manufacturing partners and methods, knowing about these things helps them make smart choices.

Precision CNC machining depends on how stiff the machine tool is, because any movement or shaking during cutting can cause mistakes in the dimensions. Machine centers of good quality are built to last and have strengthened structures that don't bend when cutting forces are applied. Precision bearings and advanced balance methods are used in the spindle systems to reduce runout and make sure smooth operation, even at high spinning speeds.

Choosing the right cutting tools and keeping them in good shape are both important for keeping the accuracy. Carbide and diamond-coated tools are harder and less likely to wear down, so they can keep their sharp cutting edges for longer production runs. Tool holds must clamp tools securely and have little movement. Before putting the tools in the machine, tool presetting systems make sure that the lengths are measured correctly.

Controls over the environment in the machining facility have a big effect on how precise the results are. Changes in temperature can make the material and machine parts have different sizes, so climate control is necessary to keep standards tight. Many precision machining shops keep temperatures within ±1°F and humidity levels under control to make sure that the qualities of the materials and the way the machines work are always the same.

Programming skills are also very important because skilled programmers can find the best cutting settings to balance work with surface finish needs. It is important to carefully figure out feed rates, spindle speeds, and tool paths based on the qualities of the material and the shape of the part. Advanced CAM software helps with this process, but the final changes need to be made by workers with a lot of experience for the best results.

Comparing CNC machining with Alternative Manufacturing Methods

There are clear benefits to CNC machining over other production methods when looking at ways to make accurate parts for aircraft and robots. This comparison helps people who have to make decisions see why computer-controlled cutting is still the best option for important jobs.

While additive manufacturing is great for making prototypes and parts with complicated shapes, subtractive manufacturing usually gets better results when it comes to accuracy and surface finish. Most 3D printing methods make parts with surface roughness levels that are much higher than flight standards. These parts need to be machined again to meet the specs. In addition, the mechanical qualities of printed materials aren't always the same as those of standard aircraft metals.

When shapes are complicated, investment casting is an option, but it adds factors that can change the uniformity of the dimensions. Tolerance stack-up that may go beyond what is needed for flight is caused by things like shrinkage rates during cooling, the accuracy of the wax pattern, and differences in the ceramic shell. Investment casting is great for making rough forms, but finish CNC machining is usually needed to get the final sizes and finishes on the surface.

Computer-controlled systems are more accurate and repeatable than traditional methods of cutting that are done by hand. Human workers change where the tools are placed and how they are cut, which makes it hard to keep the quality the same from one production batch to the next. Also, doing things by hand takes a lot more time per part, which drives up prices and delivery times for large orders.

Electrical discharge machining (EDM) is sometimes used with CNC machining to help with certain tasks. However, it removes material much more slowly. EDM is great at making parts with complicated internal features and materials that are hard to machine, but traditional machining can make most aircraft and robots parts faster.

Industry Applications and Case Studies in Aerospace and Robotics

Precision cutting is used by aerospace companies to make very important flight parts that must be completely reliable. Compressor blades and other parts of engines need complexly bent surfaces with tolerances measured in thousandths of an inch. For safe operation, these parts must keep their exact shape even when they are exposed to high temperatures and pressures. This means that manufacturing consistency is very important.

Another place where accurate cutting is essential is in the parts of landing gears. During airplane activities, these parts must be able to withstand huge pressure while still fitting perfectly with other parts. Measurement precision gained through CNC machining makes sure that loads are distributed correctly and that parts last longer, which lowers upkeep costs and raises safety gaps.

Parts like servo motor housings and precision gears need to be made with the same level of accuracy for robotics uses. Repeatability is very important for industrial robots that do assembly work, and this depends on how accurately their internal parts are measured. Even small changes in the shapes of gear teeth or bearing surfaces can add up to positioning mistakes that make the robot less useful.

For medical robots uses, the standards are very strict because these systems are often used in cases where life is at stake. To keep patients safe, surgical robot parts need to stay in exact positions. This requires manufacturing limits that can only be safely met by advanced CNC machining. Biocompatible materials are used in these situations, and they need special cutting methods to keep their qualities.

The climate in space presents unique problems to satellite and rocket parts, which need to be precise and reliable. In the hard environment of space, antenna tracking systems, solar panel deployment systems, and instrument housings all rely on parts that are carefully made to work right. Because fixes can't be done after the product has been sent out, the quality of the original making is very important.

How to Choose a CNC machining Partner for Precision Aerospace and Robotics Parts?

To find the right manufacturing partner, you need to carefully consider a number of factors that affect both the quality of the parts and the success of the project. Because aircraft and robots parts are so complicated, they need to come from sources with a track record of success and complete quality systems.

Quality approvals are the basis for judging a seller. For aircraft uses, AS9100 recognition is a must. This standard shows how well a seller can meet the aircraft industry's strict quality and paperwork standards. It depends on the product whether you need extra licenses like NADCAP for special processes or ISO 13485 for medical devices.

Manufacturing skills must match the needs of the project. This includes machine sizes, axis setups, and limits that can be reached. Five-axis machining centers can make complicated shapes in a single setup, which cuts down on setup mistakes and improves the accuracy of the dimensions. The fact that in-process measurement tools and statistical process control are available shows that quality will be maintained throughout production runs.

When you work with advanced composites and specialized aircraft metals, you need to know a lot about the materials you are using. Suppliers need to know about the special properties of materials like titanium, Inconel, and carbon fiber reinforced plastics. They also need to know how to cut and handle these materials properly. Having experience with these materials has a direct effect on both the quality of the parts and how quickly they can be made.

Project plans and performance promises are affected by lead time skills and capacity planning. Suppliers should show that they have reasonable planning systems and extra ability to deal with sudden changes in demand. For important uses where downtime costs a lot, emergency reaction skills may be needed.

Conclusion

When it comes to making high-precision aircraft and robots parts that meet strict performance standards, CNC machining is still the best way to go. With the help of cutting-edge machine tools, complex software, and all-encompassing quality systems, makers can achieve the precise measurements and high-quality finishes needed for these important uses. For precision manufacturing to go well, partners must have a track record of success, the right certifications, and a deep knowledge of the needs of aircraft and robots. As technology keeps getting better, CNC machining will change to meet even higher standards for accuracy while keeping the dependability that makes it essential for making mission-critical parts.

FAQs

How close of a range can CNC machining be used for parts in aerospace?

For aircraft parts, modern CNC machining can often get tolerances of ±0.001 inches (±0.025mm) or better. Tolerances as small as ±0.0005 inches are possible in certain situations and with the right materials. The allowed range is based on things like the shape of the part, the type of material used, the machine's capabilities, and the rules that are in place during production.

How does the choice of material affect the accuracy of making parts for robots?

Through their effects on tool wear, temperature expansion, and machine stability, material qualities have a big effect on how precise a job can be done. Because they are less hard and better at transferring heat, aluminum alloys can usually be machined to tighter standards than stainless steels. Titanium and Inconel metals need special cutting tools and conditions to be made correctly, but the results can be very precise.

What kinds of checks are used to make sure that aircraft CNC machining is accurate?

Coordinate measuring machines (CMMs) are the main way that aircraft parts are inspected to make sure they are the right size. These systems can measure complicated shapes more accurately than what is possible with standard industrial limits. Optical comparators are used for 2D measurements, surface roughness testers are used to check the finish, and special tools are used to measure things like thread pitch and concentricity.

Partner with Fudebao Technology for Precision CNC machining Solutions

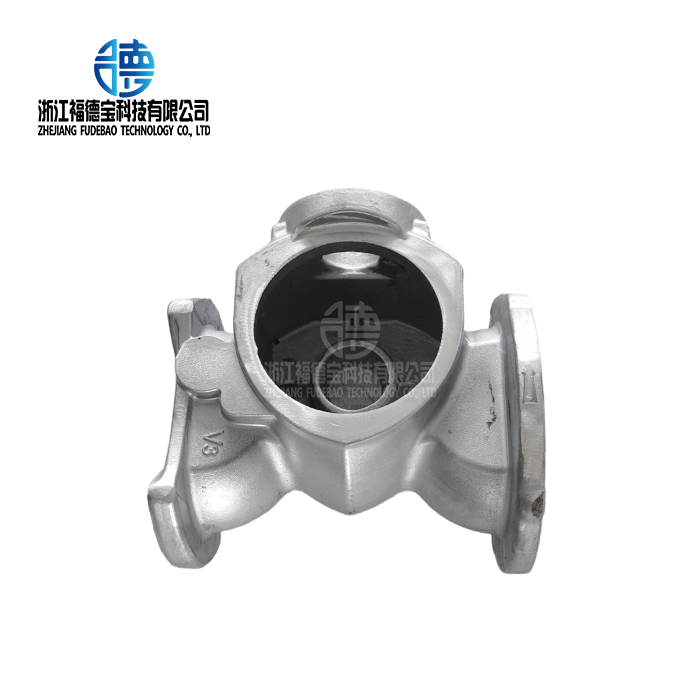

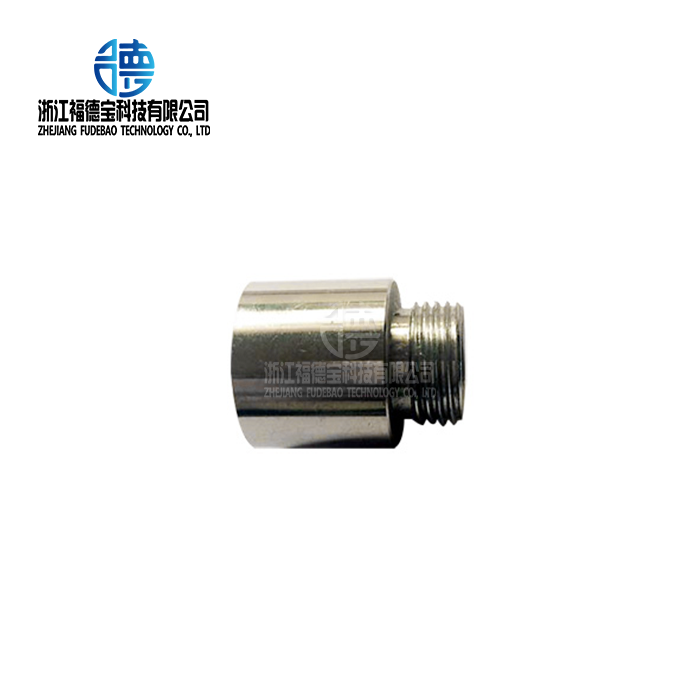

Being a top CNC machining company that makes accurate parts for aircraft, automobile, and industry uses, Zhejiang Fudebao Technology has made a name for itself. Our modern factory has advanced machine centers, CNC lathes, and casting tools that help with the whole process, from getting the raw materials to making the finished products. We regularly keep standards of ±0.05mm, meeting the strict needs of aircraft and robots clients around the world.

Our combined manufacturing method brings together precision cutting and casting under one roof. This means we don't have to use as many sources and wait times are cut down. This all-in-one service model includes die casting, low-pressure casting, and full finishing processes that can treat the surface. These processes work together smoothly to make sure that the dimensions stay the same and that quality is controlled throughout the whole production cycle.

Quality certificates and high-tech testing tools show that we are dedicated to making precise products. Coordinate measuring tools and surface finish research equipment in our measurement lab make sure that parts are made according to customer requirements. Traceability and detailed recording tools meet the needs of aircraft and provide full production records for every part.

We can help with a wide range of aircraft and robots uses because we have experience with different materials, such as aluminum alloys, stainless steel, and copper alloys. During the planning process, our engineering team works with buyers to make sure that the product can be made easily while still meeting performance standards. By working together, they can often cut costs and speed up delivery times without lowering the quality of the work.

Contact us at hank.shen@fdbcasting.com to talk about your unique needs when you need a trusted CNC machining provider for your high-precision aircraft or robots project. Based on the details of your part and when you need it, our expert team can give you full quotes and production suggestions.

References

Smith, J.R., et al. "Advanced CNC Machining Techniques for Aerospace Applications." Journal of Manufacturing Science and Engineering, Vol. 145, No. 3, 2023.

Johnson, M.K. "Precision Manufacturing in Robotics: Materials and Methods." International Journal of Precision Engineering and Manufacturing, Vol. 24, No. 8, 2023.

Williams, A.P. "Quality Systems and Certification Requirements for Aerospace Manufacturing." Aerospace Manufacturing Technology, Vol. 67, No. 4, 2023.

Chen, L.Y., et al. "Thermal Compensation Strategies in High-Precision CNC Machining." Precision Engineering Journal, Vol. 78, 2022.

Martinez, R.D. "Comparative Analysis of Manufacturing Methods for Critical Aerospace Components." Manufacturing Engineering Review, Vol. 89, No. 12, 2023.

Thompson, K.S. "Future Trends in Precision Machining for Space Applications." Aerospace Engineering Quarterly, Vol. 34, No. 2, 2023.

_1756347888208.webp)

_1756344684491.webp)

_1756348300182.webp)

_1756349146076.webp)

_1756352472762.webp)

_1756352625880.webp)