When it comes to making big unique metal parts quickly and cheaply, sand casting is the best possible method. This tried-and-true method works great for making big, complicated parts that are also flexible in form and cost-effective. More and more, sand casting is being used by the aircraft, automobile, industrial machinery, and electrical equipment industries to make special big parts. The method is flexible and can work with different metals, such as aluminum alloys, copper alloys, and stainless steel. This makes it the best choice for making large-scale complex shapes.

Understanding Sand Casting and Its Process for Large Parts

The process of sand casting is both complicated and easy to understand. It starts with making a sand mold around a carefully made design. The traditional way of using this casting method has changed a lot over the years. It now uses modern materials and precise controls to make big, complicated metal parts very accurately.

The Step-by-Step Sand Casting Process

For big parts, the sand casting method has several important steps that need specialized knowledge and tools. Pattern making is the first step, and then trained workers make exact copies of the part that is needed. These models need to take into account how much the metal will shrink and how much room there is for cutting. This is especially important for large casts where small differences in size can have a big effect on the quality of the final part.

After that, the mold is prepared using carefully made sand mixes that give the best strength and transparency. Silica sand, clay additives, and water make up green sand systems, which are great for molding big parts. The type of sand directly affects the quality of the casting. For example, the right amount of wetness and clay spread are needed to keep the mold intact while metal is poured into it.

Material Considerations for Large Castings

Different metal types can be used in large sand casts, and each one presents its own set of challenges and possibilities. Because they are so strong for how light they are, aluminum alloys are perfect for use in cars and spacecraft. Gray iron is great for bases and housings of industrial machinery because it is very good at dampening vibrations. Some types of stainless steel are very resistant to rust, making them perfect for harsh environments.

During the cooling and solidification process, big parts need to be carefully managed because differences in temperature can cause internal stresses and changes in size. Advanced cooling methods, such as controlled solidification and smart riser placement, make sure that the qualities of the material are the same all the way through the casting.

Core Advantages of Sand Casting for Large Custom Parts

When making big unique parts, the benefits of sand casting as a method of production become even more clear. For a wide range of business uses, this process is the best option because it is both highly flexible and cost-effective.

Cost-Effectiveness and Economic Benefits

Sand casting is a great way to make things because it has very low starting tooling costs compared to other ways of making things. Die casting needs expensive steel molds, but sand casting uses designs that aren't too expensive and can be changed or replaced without spending a lot of money. During the creation of a product, when design changes are typical, this freedom is very helpful.

The process works well from small amounts for prototypes to full production runs without needing a lot of extra money. Sand casting makes it possible to make large parts that would be too expensive to make any other way. This is especially true when the annual production number is between a few dozen and several thousand pieces.

Design Flexibility and Customization Capabilities

Engineers like that sand casting can handle parts with complicated internal shapes and complex exterior features. Other making methods have trouble with undercuts, internal spaces, and different wall thicknesses, but this method can handle them. This design freedom lets engineers make parts work better without making them harder to make.

Strategies for losing weight, like hollow parts and better material distribution, are possible with smart core placement and improved shaping methods. These skills are necessary for projects to make cars lighter and for improving the performance of aircraft parts.

Material Property Optimization

By choosing the right metal and heating it up, sand casting lets you precisely control the qualities of the material. Some mechanical qualities can be improved by the relatively slow cooling rates that come with sand casting. This is especially true for iron and steel metals that naturally form fine grain structures.

Comparing Sand Casting with Alternative Casting Methods

Knowing how sand casting compares to other methods of production helps people make decisions about the best way to make their big unique parts.

Sand Casting vs. Die Casting

Sand casting leads the market for big components, while die casting excels at high-volume production of small parts with tight standards. Die casting models are much more expensive and have size restrictions that make it impossible to make big parts. Sand casting can make parts that are much bigger while still being fairly accurate in terms of size for most uses.

Die casting is better for surface finish quality, but sand casting surfaces can be brought up to standards with extra grinding processes if needed. During the creation phase, sand casting has big benefits because it lets you change patterns quickly.

Investment Casting Limitations for Large Parts

It is possible to make better surface finishes and tighter standards with investment casting, but it can't be used for big parts. The process gets exponentially more expensive as the size of the part goes up, so most big apps can't use it. The largest size that can be made through investment casting is also limited by the clay shell construction.

Emerging Technologies and Their Current Limitations

Additive manufacturing technologies, such as 3D metal printing, can be used to make quick prototypes but aren't yet cost-effective enough to make big parts in large quantities. Because of limited build volumes, longer processing times, and higher material prices, these technologies are not competitive for big special casts. Instead, they are used as extras.

Best Practices and Design Tips for Large Sand Casted Parts

To get the best results from big sand casts, you need to follow tried-and-true design principles and best practices for making. Following these rules will help engineering teams make the best parts possible while lowering the risks of production.

Defect Prevention Strategies

Common casting flaws like porosity, shrinking, and hot tears can be avoided by carefully planning the design and controlling the process. Porosity usually happens when the sand system doesn't have enough air flow or too much water. When you create a mold correctly, you include opening holes that let gases escape while the metal is being poured.

Shrinkage flaws, which are more common in big casts, need filling systems that are carefully planned. Risers need to be the right size and placed so that they can move liquid metal to the areas that will harden last. This will make up for the volume loss that happens as the casting cools.

Optimal Design Guidelines

Uneven wall thickness in sand casting stops different cooling rates that cause stress inside the structure and could lead to breaking. Gradual changes between thick and thin parts help spread out the heat stress more evenly. Draft angles, which are usually between 1 and 3 degrees, make it easier to get rid of patterns and improve the quality of the surface.

Corner curves spread out stress points and make it easier for metal to move during filling. Sharp corners trap air and cause turbulence, which can lead to flaws. Large curves, especially at section changes, make it easier to cast and improve mechanical performance.

Modern Process Innovations

Simulation software on computers lets foundries improve casting ideas before they are made. These tools guess how metal will move, find places where defects might happen, and make the best use of gate and lift systems. Simulation cuts down on the number of times you have to try something and see what works and what doesn't.

Modern sand systems, like the resin-bonded and sodium silicate processes, are better than traditional green sand at keeping their shape and beauty of the surface. These methods work especially well for big, complicated casts that need to be made with very tight standards.

Procurement Insights and Finding Reliable Sand Casting Partners

To find good casting partners, you need to carefully look at their skills, quality processes, and output ability. Large sand molds are hard to make, so suppliers need to have a lot of knowledge and a strong infrastructure.

Essential Supplier Qualification Criteria

An evaluation of production capacity looks at more than just the ability to melt things. It also looks at methods for moving big parts around. Foundries must show that they have enough floor room, crane capacity, and finishing tools to safely and efficiently handle large parts.

Systems for quality control should have a lot of checking tools, especially coordinate measuring machines that can work with big parts. When PPAP paperwork is needed in the aircraft and automobile industries, statistical process control and tracking tools become very important.

Understanding Pricing and Lead Time Factors

The prices for sand casting usually include the costs of the metal, the design, and the work that goes into making the casting. When handling large parts, you may need to take extra care, which can change the total cost. Knowing about these things helps buying teams make budgets that are reasonable and negotiate well.

Lead times are highly affected by the supply of patterns, the schedule for production, and the needs for finishing. It can take 8 to 12 weeks from the time an order is placed until the part is delivered, especially if it needs to be machined again.

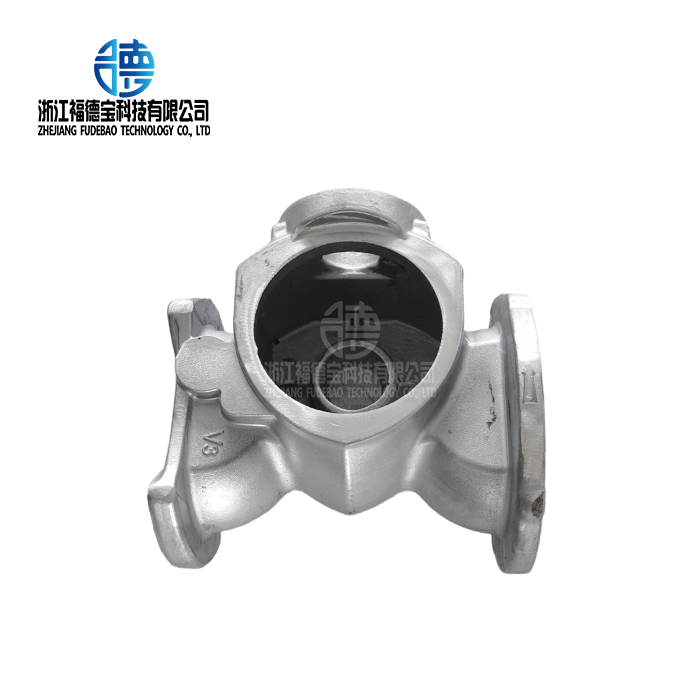

Fudebao Technology: Your Expert Sand Casting Manufacturer

Zhejiang Fudebao Technology Co., Ltd. is a leading aluminum factory that focuses on making big custom parts with precise sand casting for a variety of businesses. Our wide range of skills covers the whole production process, from the initial melting to the final surface treatment. This means that we can deliver your product from blank to finished in just one visit.

Advanced Manufacturing Capabilities

Modern machines like high-speed machining centers, CNC lathes, low-pressure casting machines, and die casting tools are housed in our building. With this unified method, we can reach standards of up to ±0.05mm, which meets the exact needs of precise parts for cars, medical equipment housings, and aircraft parts.

We are experts at making aluminum alloys, copper alloys, and stainless steel. We serve customers around the world in the automobile, industrial equipment, tool production, and aircraft industries. We switched from working with middlemen to working directly with foreign names like American HAAS automatic machine tools and ESS energy storage batteries. This shows that we are dedicated to providing the best quality products.

Quality Assurance and Certification

Our quality control tools make sure that all of our production runs have the same level of standard. For aircraft and automobile uses, we keep full paperwork systems that meet PPAP standards and allow full tracking. Our team works closely with buying leaders, tech managers, and quality teams to make sure that everything fits perfectly with the project's requirements.

Conclusion

Sand casting is still the best way to make big unique parts because it gives you the most design options, the lowest cost, and the widest range of materials. The process can work with complicated shapes and keep costs low across a range of output rates. Modern improvements to mold-making, modeling software, and quality control methods keep making sand casting better, which makes it more appealing for demanding uses. To be successful, you need to choose manufacturing partners that are skilled, have the right tools and quality processes, and have experience working with big parts. The benefits of sand casting become more and more clear as industries keep asking for bigger and more complicated metal parts, cementing its place as the best way to make unique large-scale components.

FAQs

What is the biggest size that sand cast parts can be?

The only thing that limits how big a part can be made by sand casting is the tools used in the foundry, not the process itself. Parts that measure many meters and weigh several tons are regularly made. The main problems are the size of the crane, the amount of floor room, and the melting capacity of the furnace.

What's the difference between sand casting and other ways of getting a smooth surface?

Surface finishes made by sand casting usually range from 125 to 500 microinches Ra, but this depends on the type of sand used and the way it is shaped. Even though secondary grinding processes can't make the surface as smooth as die casting or investment casting, they can do it when they need to.

When should I expect to get my big handmade sand cast parts?

Large custom parts usually have lead times between 6 and 12 weeks, but this depends on how complicated they are, what material is chosen, and how they need to be finished. Making a pattern generally takes two to four weeks, and casting and finishing take another four to eight weeks.

Partner with Fudebao Technology for Your Large Casting Needs

Are you ready to use precision sand casting to make your big custom part ideas come to life? Fudebao Technology delivers excellent results by combining decades of casting experience with current production skills. Our team specializes in castings made of aluminum alloy, copper alloy, and stainless steel. They work with car, industrial, and aircraft clients all over the world. From the first planning meeting to the final delivery, we take care of everything to make sure your project meets all technical and quality standards. We keep the best standards and offer reasonable wait times because we are a trusted sand casting source. Get in touch with our expert team to find out how our advanced skills can help you with your next project. Email us at hank.shen@fdbcasting.com to talk about your unique needs and get thorough quotes for your project.

References

Campbell, John. "Complete Casting Handbook: Metal Casting Processes, Metallurgy, Techniques and Design." Second Edition, Butterworth-Heinemann, 2015.

Brown, John R. "Foseco Foundryman's Handbook: Facts, Figures and Formulae." Eleventh Edition, Butterworth-Heinemann, 2000.

Beeley, Peter. "Foundry Technology." Second Edition, Butterworth-Heinemann, 2001.

American Foundry Society. "Casting Design and Performance." American Foundry Society Publications, 2009.

Stefanescu, Doru M. "Science and Engineering of Casting Solidification." Third Edition, Springer International Publishing, 2015.

Jolly, Monroe R. "Sand Casting: Principles and Practice of Green Sand Molding." Institute of Cast Metals Engineers, 2014.

_1756348227989.webp)

_1756361423150.webp)