To successfully buy copper castings from China, you need to use strict quality control methods to make sure the products are reliable and work well for a long time. As a result of their low prices and improved production methods, Chinese makers have become the world leaders in copper alloy casting technologies. To get stable quality, though, you need to carefully screen your suppliers, follow strict testing procedures, and keep a close eye on the whole manufacturing process. Quality control not only keeps your money safe, but it also builds stronger relationships with dependable providers, which is important for long-term success in B2B buying.

Understanding Copper Castings and Their Manufacturing in China

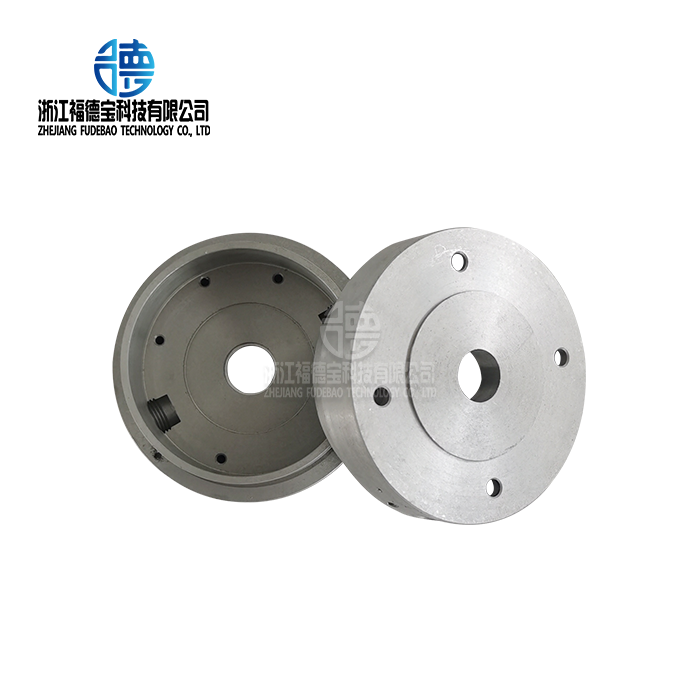

Copper casting is the process of putting liquid copper or copper alloys into precise molds to make parts that conduct electricity and heat very well. Some of the complex metals that are used in Chinese foundries are brass, bronze, and special copper alloys that are each made for a specific industrial purpose. There are many different casting methods used in making, each one best suited to a specific production need or part complexity.

Primary Casting Methods in Chinese Foundries

Three main casting methods are used by Chinese producers. Each has its own benefits for different uses. Sand casting is still the most flexible method because it can be used to make big parts with complicated shapes and the cost of the tools is low. Investment casting gives the best surface finish and most accurate measurements, which makes it perfect for complicated pieces that don't need much cutting. Centrifugal casting makes cylinder-shaped parts with great material density and dynamic qualities, which make them ideal for use in bearings and bushings.

Material Properties and Alloy Selection

Modern foundries in China offer a wide range of alloys to meet the needs of different industries. For car uses, brass alloys are easy to make and don't rust. Bronze alloys, on the other hand, are better at resisting wear in heavy machinery parts. Tin, aluminum, or nickel are added to specialized copper alloys to improve their strength, conductivity, or heat stability, among other things. By understanding these features of the material, buyers can choose the best metals for their individual needs.

Key Quality Control Challenges When Importing Copper Castings from China

Importing metal casts such as copper castings comes with quality risks that need to be managed in a responsible way. Common flaws that can affect how well a part works are porosity, inclusions, size changes, and surface irregularities. Most of the time, these problems are caused by inconsistent raw material quality, differences in the process, or poor controls in the casting. Importers can take focused quality assurance steps when they know about possible problems.

Understanding Industry Standards and Compliance

International quality standards are important ways to measure how well a company can do their job. ISO 9001 approval shows that quality management is done in a planned way, and ASTM standards spell out the features of materials and how they must be tested. To meet the needs of the global market, more and more Chinese foundries are adopting these foreign norms. Suppliers who follow well-known standards usually keep better track of their processes and provide more consistent product quality.

Common Defects and Their Prevention

The most common quality problem in copper castings is porosity, which can be caused by trapped air or shrinking during solidification. Surface flaws like cold shuts, misruns, and additions can change how something looks and how it works. Differences in dimensions can happen because of pattern wear, cast distortion, or poor process control. To avoid these problems, you need to carefully choose your suppliers, check the materials, and keep an eye on the process throughout the production cycle.

Proven Quality Control Steps for Importers

Quality assurance that works for copper castings starts with a full review of the provider and goes through all stages of production. Importers who are good at what they do use multi-layered checking methods that include audits of suppliers, checks of materials, process tracking, and tests of the finished product. These organized methods cut down on quality risks by a large amount and boost trust in the supplier's abilities.

Supplier Audit and Certification Verification

Supplier checks look closely at the foundry's skills, the state of its tools, and its quality control methods. Facilities for freezing, making molds, casting processes, and finishing operations are some of the most important parts of the evaluation. Verification of certification shows that foreign standards are being met and shows a dedication to high achievement. Suppliers with a good reputation let checks happen and make their sites and records easy to access.

Advanced Testing and Inspection Protocols

Non-destructive testing methods give important information about the quality of the casting without affecting the usefulness of the result. Ultrasonic testing finds structural breaks, while X-ray analysis finds internal holes and inclusions. Coordinate measuring tools are used for measuring dimensions to make sure they meet engineering standards. Chemical makeup analysis checks the qualities of a metal and makes sure that materials can be tracked all the way through the supply chain.

Third-Party Inspection Services

Independent inspection companies can check the quality of a product without bias, which is especially helpful for important projects or when starting a new relationship with a seller. Some of these services are checks before production, tracking during production, and reports on the final review. Having a third party involved in the buying process makes it more clear and gives real proof of quality compliance. There are many offices of foreign inspection companies in China, making it easy to get skilled help.

Comparing Copper Castings from China with Other Global Suppliers

When it comes to the global copper casting market, Chinese producers have clear benefits thanks to their reasonable pricing and improved technical skills. Knowing these comparison strengths helps buyers make smart choices about where to buy things and how much they plan to pay for quality, delivery, and service.

Cost Competitiveness and Value Proposition

Chinese foundries usually have good price systems for copper castings that don't lower quality standards too much. This competitive edge comes from economies of scale, efficient production methods, and lower labor costs. But buyers should think about the total cost of ownership, which should include shipping, customs fees, and any quality problems that might come up. Price isn't the only thing that makes it valuable; professional help, the ability to customize, and the freedom of the supply chain are also important.

Production Flexibility and Lead Times

Chinese providers are great at meeting special needs and keeping track of changing order numbers. Many foundries have faster lead times than their Western peers, especially when it comes to making prototypes and small batches. When jobs need to be finished quickly or when the market changes, this flexibility comes in handy. When sellers have production freedom, they can quickly meet the needs of the market while keeping their supplies efficient.

Seamless Integration: Managing Logistics and After-Sales Support

Importing copper castings that work well takes careful planning of operations, following customs rules, and help after delivery. Managing these parts well keeps the supply chain running smoothly and helps you keep long-term relationships with suppliers.

Logistics Coordination and Customs Compliance

When metal works are shipped internationally, they need to be packed in a certain way and go through certain customs processes. Freight forwarders with a lot of experience know how to handle these issues and help keep delays and extra costs to a minimum. The right grouping under standardized tariff schedules makes sure that tax estimates are correct and that regulations are followed. Shipping problems can be avoided if wholesalers, transport providers, and customs brokers can talk to each other clearly.

Post-Delivery Support and Warranty Services

Reliable customer service after the sale is what sets great sellers apart from average ones. Full insurance policies, quick expert support, and clear return processes protect buyers' investments and show that suppliers trust their goods. When contact lines work well, problems with quality or technical questions can be solved quickly. These support services are very important for the long-term success of partnerships and the continuation of operations.

Conclusion

When paired with thorough quality control plans, importing copper castings from China can open up a lot of doors. To have good buying partnerships, you need to know how things are made, follow strict checking procedures, and only work with certified sellers. Quality management that works well will protect your investment and give you access to China's advanced casting capabilities and low prices. A careful review of the seller, organized testing methods, and dependable transportation planning make sure that the quality of the products you buy and the security of the supply chain for your business uses are always the same.

FAQs

What kinds of licenses should I ask Chinese copper casting companies to give me?

Look for certifications that are known around the world, like ISO 9001 for quality management systems and the right ASTM standards for material requirements. These licenses show that you are committed to foreign standards and follow a method for quality. Depending on the needs of your business, you may need extra licenses like IATF 16949 for car use or AS9100 for aircraft use.

How can I be sure that the features of the copper casting material meet the requirements?

Ask for full test results on the material that include a study of its chemical makeup, testing of its mechanical properties, and a metallic examination. Testing in a separate lab gives a neutral check of the material's qualities and quality standards. To make sure the quality of the materials is always the same, set clear acceptance standards and ask providers to include proof of compliance with every order.

How long does it usually take to get a handmade copper casting order?

Depending on the complexity of the part, the number of orders, and the needs of the casting method, standard wait times are between 4 and 8 weeks. Delivery plans are affected by things like the time it takes to make tools, the time it takes to get prototypes approved, and the time it takes to ship them. It may be possible to meet rush requests with higher prices, but long production runs may need more time to make sure there is enough capacity.

Partner with Fudebao Technology for Premium Copper Castings

Precision metal casting and cutting are what Zhejiang Fudebao Technology does best. They make great copper castings for use in cars, factories, and spacecraft. Our modern factory has high-speed machining centers, CNC lathes, and advanced casting tools that can do the whole production process, from melting the metal to treating the surface. We keep standards on sizes up to ±0.05mm and offer one-stop delivery for parts that are blank to finished.

Our complete quality control system is in line with ISO and ASTM standards, which means that the quality and performance of our products will always be the same. We work with well-known foreign names, like American HAAS automation and ESS energy storage systems, which shows that we can meet strict requirements. Our skilled engineering team offers expert advice and unique solutions for copper casting needs that are very complicated.

Reliable partners who comprehend your quality needs and delivery standards are the foundation of a successful copper castings provider partnership. Get in touch with our technical experts at hank.shen@fdbcasting.com to find out how our precision copper castings can improve the performance of your product.

References

American Society for Testing and Materials. "Standard Specification for Copper and Copper-Alloy Castings." ASTM International Annual Book of Standards, 2023.

International Organization for Standardization. "Quality Management Systems - Requirements for Automotive Production and Service Parts Organizations." ISO/TS 16949:2016.

China Foundry Association. "Annual Report on Chinese Casting Industry Development and Market Analysis." Beijing: Metallurgical Industry Press, 2023.

Smith, Robert J. and Chen, Wei. "Non-Destructive Testing Methods for Copper Alloy Castings: A Comprehensive Guide." Journal of Materials Engineering and Performance, Vol. 32, No. 8, 2023.

European Copper Institute. "Copper Alloys for Industrial Applications: Properties, Selection and Quality Control." Brussels: European Copper Institute Technical Publications, 2022.

Wilson, Michael K. "Global Trends in Metal Casting Supply Chain Management: Asia-Pacific Market Analysis." International Foundry Research, Vol. 45, No. 3, 2023.

_1756345939856.webp)

_1756348711711.webp)

_1756349696500.webp)

_1756352340434.webp)

_1756352712247.webp)

_1756361494985.webp)