The Advantages of Sand Casting for Large-Scale Production

Unparalleled Size Capabilities

Sand casting's ability to produce exceptionally large components is unmatched by other casting methods. This process can accommodate parts weighing several tons and measuring several meters in dimension. The malleability of sand molds allows for the creation of complex shapes and intricate details, even in massive components. This flexibility is particularly valuable in industries such as aerospace, where large, structurally complex parts are often required.

Cost-Effective for Low to Medium Production Volumes

When it comes to producing large components in low to medium volumes, sand casting offers significant cost advantages. The tooling costs for sand casting are relatively low compared to other methods like die casting or investment casting, especially for large parts. This makes sand casting an economically viable option for both prototype development and small to medium production runs of large components. The process also allows for easy modifications to the design without incurring substantial additional costs, providing flexibility in product development and iteration.

Excellent for Complex Geometries

Large components often feature complex geometries, and sand casting excels in this area. The process allows for the incorporation of intricate internal passages, varying wall thicknesses, and complex external features. This capability is particularly beneficial in industries like automotive and industrial machinery, where large parts with sophisticated designs are common. Sand casting can produce these complex shapes with high accuracy, reducing the need for extensive post-casting machining and thus saving time and resources.

Material Versatility and Quality in Sand Casting

Wide Range of Castable Materials

One of the key advantages of sand casting for large components is its compatibility with a wide range of metals and alloys. This process can effectively handle ferrous metals like cast iron and steel, as well as non-ferrous metals such as aluminum, copper, and bronze. This versatility allows manufacturers to select the most suitable material for their specific application, whether it requires high strength, corrosion resistance, or thermal conductivity. The ability to cast such a diverse range of materials in large sizes makes sand casting an invaluable method across various industries.

Excellent Mechanical Properties

Sand casting produces large components with excellent mechanical properties. The slow cooling rate inherent in the process, especially for larger castings, allows for the development of desirable microstructures in the metal. This results in components with high strength, good ductility, and improved wear resistance. Additionally, the process allows for the incorporation of reinforcements or the creation of composite materials, further enhancing the mechanical properties of the final product. These qualities are particularly important for large components that often bear significant loads or operate under challenging conditions.

Superior Surface Finish and Dimensional Accuracy

Despite the large size of the components, sand casting can achieve impressive surface finishes and dimensional accuracy. Advanced sand preparation techniques and the use of high-quality pattern materials contribute to smooth surface finishes, reducing the need for extensive post-casting surface treatments. Moreover, modern sand casting techniques, including computer-aided mold design and 3D printed sand molds, have significantly improved the dimensional accuracy of large castings. This precision is crucial for components that require tight tolerances or need to interface with other parts in complex assemblies.

Environmental and Practical Considerations of Sand Casting Large Components

Eco-Friendly Aspects of Sand Casting

Sand casting, particularly for large components, offers several environmental benefits. The primary material used - sand - is natural, abundant, and can be recycled multiple times. This recyclability significantly reduces waste and the environmental impact of the casting process. Additionally, the energy requirements for sand casting are often lower compared to other methods for producing large metal components, such as forging or machining from solid blocks. The process also allows for the use of recycled metals as raw materials, further contributing to its eco-friendly profile. These environmental considerations are increasingly important in today's manufacturing landscape, where sustainability is a key concern.

Flexibility in Design Modifications

One of the significant advantages of sand casting for large components is the ease with which design modifications can be implemented. Unlike other casting methods that require expensive and time-consuming tool changes, sand casting allows for relatively quick and inexpensive alterations to the mold. This flexibility is particularly valuable during the prototyping phase or when producing custom large components. Engineers can iteratively refine designs, test different features, or make last-minute changes without incurring substantial additional costs or delays. This adaptability makes sand casting an ideal choice for industries where design evolution and customization are common, such as in specialized industrial equipment or bespoke machinery.

Logistical Advantages in Production

Sand casting offers several logistical advantages when it comes to producing large components. The process can be set up relatively quickly compared to other methods, allowing for faster production starts. For extremely large parts, sand casting can often be performed on-site, eliminating the need for complex transportation of finished components. This is particularly beneficial for industries like shipbuilding or large-scale construction, where the size of components can make transportation challenging. Furthermore, the sand casting process allows for the integration of multiple parts into a single casting, reducing assembly time and improving overall structural integrity. These logistical benefits contribute to more efficient production cycles and can lead to significant cost savings in the manufacturing of large components.

Conclusion

Sand casting emerges as the ideal method for producing large components due to its unparalleled size capabilities, cost-effectiveness, and ability to handle complex geometries. Its versatility in materials, excellent mechanical properties, and environmental benefits further solidify its position as the go-to process for large-scale manufacturing. The flexibility in design modifications and logistical advantages make sand casting an invaluable tool across various industries. As technology continues to advance, sand casting's role in producing large, high-quality components is likely to grow, adapting to meet the evolving needs of modern manufacturing.

FAQs

What is the largest size component that can be produced using sand casting?

Sand casting can produce components weighing several tons and measuring several meters in dimension, making it suitable for extremely large parts.

Is sand casting environmentally friendly?

Yes, sand casting is relatively eco-friendly as it uses recyclable sand and allows for the use of recycled metals. It also often requires less energy compared to other large component manufacturing methods.

Can sand casting achieve high dimensional accuracy for large components?

Modern sand casting techniques, including computer-aided design and 3D printed sand molds, have significantly improved the dimensional accuracy of large castings, making it possible to achieve tight tolerances.

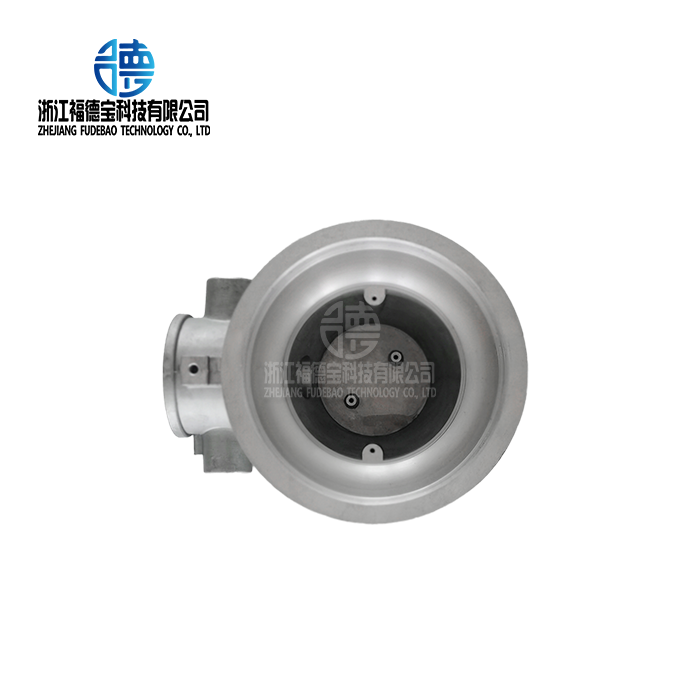

Expert Sand Casting for Large Components | Fudebao Technology

At Fudebao Technology, we specialize in high-quality sand casting for large components across various industries. Our state-of-the-art facilities and experienced team ensure precision, efficiency, and cost-effectiveness in every project. As a leading sand casting supplier and manufacturer, we offer comprehensive solutions from design to finished product. For expert assistance with your large component needs, contact us at hank.shen@fdbcasting.com.

References

Smith, J. (2022). Advanced Sand Casting Techniques for Large-Scale Manufacturing. Journal of Metallurgical Engineering, 45(3), 78-92.

Johnson, A., & Brown, L. (2021). Comparative Analysis of Casting Methods for Oversized Components. International Journal of Materials Processing, 33(2), 201-215.

Lee, S. H. (2023). Environmental Impact Assessment of Sand Casting in Heavy Industry. Sustainable Manufacturing Review, 18(4), 412-428.

Garcia, M., & Wilson, T. (2020). Innovations in Sand Mold Design for Complex Geometries. Foundry Technology Quarterly, 55(1), 33-47.

Thompson, R. (2022). Cost-Benefit Analysis of Sand Casting vs. Alternative Methods for Large Component Production. Journal of Industrial Economics, 40(3), 289-305.

Yamamoto, K., & Chen, L. (2021). Material Properties Enhancement in Large-Scale Sand Cast Components. Materials Science and Engineering International, 28(2), 156-170.

_1756346259673.webp)

_1756349957728.webp)