To improve the surface finish of sand castings, you need to know how different factors work together to make the best conditions for making casts that are smooth and free of defects. Technology for sand casting has come a long way. Now, producers can get better surface quality by carefully controlling the mold materials, filling settings, and post-processing methods. This all-around method makes sure that parts meet strict standards for automobile, aircraft, and industrial tools while still being cost-effective.

Good surface finish affects how well a product works, how happy customers are with it, and how much it costs to make. If the surface isn't in good shape, it could mean bigger cutting margins, more finishing steps, or even the part being rejected. When buying managers and engineering teams understand these problems, they can make better decisions about casting methods and which suppliers to choose. Due to the difficulty of maintaining a uniform surface quality in a foundry, it is necessary to use organized methods that balance technical needs with cost concerns.

Understanding Surface Finish Issues in Sand casting

In sand casting, surface finish includes a number of factors, such as how rough it is, how regular the texture is, and whether there are any obvious flaws. Throughout the manufacturing cycle, these traits have a big effect on both how well the product works and how costs are managed. Common surface flaws are caused by the type of mold material, how flexible the metal is when it's poured, managing the temperature, and controlling the rate of cooling.

Root Causes of Surface Defects

Preparing the mold is the most important thing that affects the quality of the finished surface. How the liquid metal interacts with the mold space is directly related to the size distribution of the sand grains, the amount of water present, and the choice of binder. Rough surfaces are caused by coarse sand grains and steam spots that form when there is too much wetness. Temperature and speed of the metal pour are also very important for surface formation. If these factors are not right, it can lead to turbulence, cold shuts, or metal going through the mold face.

Impact on Manufacturing Economics

When the surface finish is bad, there are real economic effects that can be seen, like more trash, longer wait times, and more finishing processes. Studies have shown that surface-related flaws are responsible for about 15–25% of casting rejects in normal foundry operations. Because of these problems, surface quality is very important for uses in aircraft and cars. It affects things like paint bonding, stress strength, and resistance to wear.

Analyzing Key Factors Affecting Surface Finish Quality

In metal casting, such as in sand casting, the quality of the surface rests on factors that can be changed and that can be optimized by engineering teams using structured analysis. When procurement workers understand these factors in the context of sand casting, they can set up the right methods and properly rate the skills of suppliers.

Mold Material Selection and Preparation

Because of the way their grains are structured and how they are bound together, green sand and resin-bonded systems can finish the surface in different ways. Green sand molds usually make surfaces that are 100 to 400 microinches rough. Resin-bonded methods, on the other hand, can get surfaces that are 50 to 200 microinches rough because the grains are better distributed and the surface is more stable. Which of these methods to use relies on the complexity of the part, the amount of production, and the surface quality standards that need to be met.

How the sand is prepared has a big effect on how solid the mold surface is. The right way to mix makes sure that the glue and wetness are evenly distributed, and the right way to press makes sure that the mold mass stays the same. Modern foundries use automatic mixing systems that keep the exact amounts of sand to glue. This makes the surface results more consistent across production runs.

Metal Selection and Process Parameters

Different metal systems react with mold materials in their own unique ways, which changes how surfaces are formed. Because they are very fluid and don't react much with silica sand, aluminum alloys usually make smoother surfaces. Careful temperature control is needed for cast iron to keep carbides from forming at the mold contact. Specialized mold coats are helpful for steel castings to keep metal from penetrating the mold.

Optimizing the pouring temperature in sand casting strikes a balance between the need for flow and the need for a good surface. In sand casting, mold cracking and metal penetration can happen when temperatures are too high, while cold shuts and partial fills can happen when temperatures are too low. According to data from the industry, keeping filling temperatures within ±25°F of the best values for sand casting can cut down on surface flaws by up to 40%.

Proven Techniques to Improve Surface Finish in Sand casting Production

To use organized methods to improve the surface finish, work needs to be planned between the steps used to prepare the mold, the casting parameters, and the post-processing steps. Foundries that are good at what they do use these tactics to keep improving quality while keeping production costs low.

Advanced Mold Preparation Methods

Modern mold preparation includes a number of important changes that directly improve the quality of the surface. These methods have worked well in a number of situations:

The following mold optimization techniques make the surface better in a way that can be measured:

- Fine-grain sand systems: Using AFS grain fineness numbers above 60 makes mold surfaces smoother, which is directly reflected in the finish of the casting. Compared to traditional sand systems, this method makes the surface 30–50% smoother while still letting enough gas escape.

- Specialized finishes for molds: Using coats that are based on alcohol or water makes a buffer between the heated metal and the sand grains. These coats make the surface smoother, stop metal from penetrating, and make cleaning easier.

- Controlled drying methods: Using precise drying processes gets rid of flaws caused by wetness and makes the mold surface stronger. Drying properly lowers surface marks caused by gas and raises the security of the shape during the casting process.

These changes to mold preparation work together to make the best conditions for making a smooth surface. When foundries use full mold preparation programs, surface-related rejects usually go down by 25 to 40 percent.

Process Control and Post-Casting Treatments

The main goal of optimizing casting parameters is to control how metal flows and how it solidifies. The design of the gates affects how the liquid metal enters the mold hole, which changes the surface formation by controlling the flow speed and roughness. Bottom gating devices usually make the surface better by reducing metal splash and rust buildup.

Post-casting processes give you more chances to smooth out the surface and fix small flaws that might show up during solidification. Shot blasting gets rid of sand particles that are stuck on the surface and rust, making the structure of the whole casting uniform. After that, the surface is ground and polished to meet particular standards for precision uses.

Comparison of Sand casting Surface Finish with Alternative Casting Methods

Technology improvements have made it much easier to finish the surface of a sand casting. However, direct comparisons with other ways show that each has its own pros and cons for different uses.

Competitive Analysis of Casting Methods

Die casting always gives the best surface finish, with a range of 32 to 63 microinches Ra straight from the casting process. However, die casting needs a lot of money to buy the tools it needs and can't make parts that are very big. Investment casting has longer lead times and higher costs per piece, but it makes surfaces that are very good for complex shapes.

New developments in sand casting technology, like 3D printed models and more advanced binding systems, are closing the gap in surface quality. Because of these improvements, sand casting can now get surface roughness values that are close to die casting quality. It can still do this while keeping the freedom and cost benefits that make it a good choice for making bigger parts in smaller batches.

How to Select Sand casting Suppliers that Ensure High-Quality Surface Finish?

When choosing a supplier for a high-quality surface finish, you need to look at their professional skills, quality methods, and ways of controlling the process. For partnerships to work, the skills of each provider must be matched with the unique needs of the production while clear quality standards are set.

Key Evaluation Criteria

Quality licenses are a good way to get an idea of a supplier's skills, but to get a more complete picture, you need to look at their real process control measures and tools. Suppliers should show that they can consistently achieve a good surface finish by showing statistical process control data and customer references from similar uses.

The choice of mold material, temperature control systems, and post-processing options for sand casting should all be talked about in technical terms. When it comes to improving casting designs in sand casting to get the needed surface quality while keeping costs low, suppliers with up-to-date tools and skilled engineering support can be very helpful.

Conclusion

In sand casting, you need to pay careful attention to mold preparation, process control, and post-processing methods in order to get a better surface finish. To be successful, you need to know how these things affect each other and use complete quality control methods. Modern sand casting technology opens up a lot of ways to get better surface quality while keeping the cost and freedom benefits that make this process appealing for a wide range of uses.

Partnering with providers who have both professional know-how and high-tech tools is the key to improving the surface finish over time. As casting technology keeps improving, companies that put money into process efficiency and quality control will be able to meet the high standards of today's precision uses with better and better surface finishes.

FAQs

What kinds of sand give the best surface finish for casting?

High-quality resin binders and fine silica sand with an AFS grain fineness number above 60 usually give the best surface finish results. The most important ones are even spread of grain sizes, low clay content, and controlling wetness properly while making the mold.

How does managing the cooling rate change the quality of the end surface?

Controlled cooling stops solidification from happening too quickly, which can lead to cracks on the surface, rough textures, and stresses inside the material. Gradual cooling makes it possible for the metal to solidify evenly, which smooths out the surface and improves the general strength of the casting by promoting better grain structure formation.

Can post-processing make up for a bad surface finish that was there to begin with?

Post-processing steps like shot blasting and grinding can make the surface look better, but they can't fully make up for problems with the mold preparation itself. For best results, use the right casting methods at the start and the right ending steps, instead of just fixing things after they've been made.

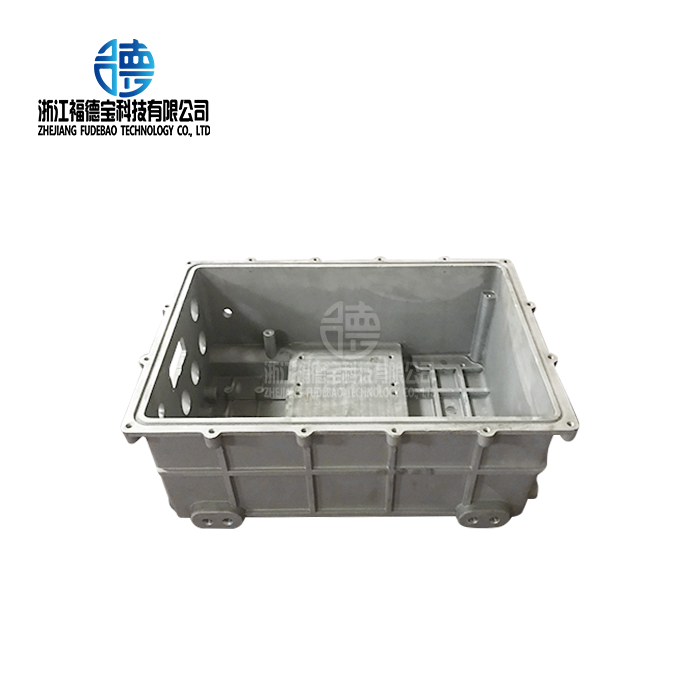

Partner with Fudebao Technology for Superior Sand casting Solutions

For the best surface finish on your casting projects, you need to work with sand casting makers who have a lot of experience and know how to balance quality and speed. Zhejiang Fudebao Technology Co., Ltd. is an expert in casting solutions made of aluminum alloy, copper alloy, and stainless steel that meet the strict surface quality needs of automobile, industrial equipment, and aircraft uses.

Our full range of manufacturing services covers the whole production cycle, from melting to surface treatment. We make sure that quality control is maintained at all stages of the process. Our high-speed machine centers, CNC lathes, and modern casting tools can achieve accuracy of ±0.05mm, and they make sure that the final parts meet strict surface finish requirements. Our skilled engineers work closely with customers to make sure that the plans for castings produce the best surface quality at the lowest cost, whether they are making a sample or a lot of parts.

Discover the benefits of working with a sand casting provider that is committed to always getting better and making sure their customers are happy. Email us at hank.shen@fdbcasting.com to talk about your unique surface finish needs and find out how our knowledge can help you make your products better and more efficiently.

References

Campbell, John. "Complete Casting Handbook: Metal Casting Processes, Metallurgy, Techniques and Design." 2nd Edition, Butterworth-Heinemann, 2015.

Brown, John R. "Foseco Foundryman's Handbook: Facts, Figures and Formulae." 11th Edition, Elsevier Science & Technology, 2000.

Beeley, Peter R. "Foundry Technology." 2nd Edition, Butterworth-Heinemann, 2001.

American Foundry Society. "Sand Casting Manual." 6th Edition, American Foundry Society Publications, 2018.

Stefanescu, Doru M. "Science and Engineering of Casting Solidification." 3rd Edition, Springer International Publishing, 2015.

Jain, P.L. "Principles of Foundry Technology." 5th Edition, Tata McGraw-Hill Education, 2014.

_1756348227989.webp)

_1756349696500.webp)

_1756349957728.webp)

_1756352561845.webp)