One of the best ways to make big, complicated metal parts for a wide range of industrial uses is through low pressure casting. This advanced casting method uses controlled pressure to push liquid metal into molds, making the quality better than with older gravity casting methods. This method works especially well for making parts with complicated shapes, thick walls, or that need to be very accurately measured. This process is used in many fields, from the auto industry to aircraft, to make parts that are strong but not too heavy and meet strict performance standards while still being cost-effective to make.

Understanding Low pressure casting Technology

A complex system makes the low pressure casting process work. Molten aluminum runs up into molds while the pressure is carefully managed. Unlike regular high-pressure die casting, this method uses low pressure, usually between 0.1 and 1.0 bar. This lets the metal run smoothly and avoids air bubbles and turbulence.

The first step in the casting process is melting aluminum metal in special ovens that are kept at the right temperature. The liquid metal then moves through a lift tube that is linked to the mold hole that is above the burner. Under controlled pressure, the liquid aluminum slowly fills the mold. This makes sure that all the holes are filled and the metal stays solid throughout the process.

Modern low pressure casting tools have high-tech automatic systems that very precisely watch over pressure, temperature, and time factors. With these systems, makers can get uniform results across production runs while still being able to change settings to fit different part shapes and metal types.

Superior Advantages for Large and Complex Components

It can be hard to make big metal parts, but low pressure casting is a good way to solve these problems because of the way it works. The controlled filling method makes sure that the metal is spread out evenly across complicated shapes, which lowers the flaws that often happen with rough flow patterns.

Here are some of the main benefits this casting method offers for making complicated metal products:

Better Structural Integrity: The controlled pressure process gets rid of gas gaps and shrinking flaws that usually happen in big casts. This makes parts with better mechanical properties and dependability performance.

Dimensional Precision: Tight tolerance control lets makers regularly reach levels of accuracy of ±0.05mm, which cuts down on the need for extra cutting and the costs that come with it.

Material Optimization: The bottom-gating system makes good use of metal with little waste because extra material stays in the kiln instead of being used to make big track systems.

Complex Geometry Capability: The gentle filling process can work with complicated internal pathways, thin walls, and undercuts that are hard for other casting methods to handle.

These benefits directly lead to lower costs and better performance for makers looking for dependable production solutions for tough jobs.

Comparative Analysis with Alternative Casting Methods

Procurement professionals can make better choices based on project needs and output goals when they know how low pressure casting stacks up against other metal casting methods.

When it comes to bigger parts, the low pressure method is clearly better than high pressure die casting. Die casting is great for making a lot of small parts, but low pressure casting is better for making bigger shapes because it doesn't use high pressures that can damage molds and bend parts.

One more option is gravity casting, which works well for simple shapes. But this old way of doing things doesn't have the controlled filling features that make sure the quality of complicated parts is always the same. Unpredictable metal flow patterns that can lead to flaws in gravity-cast components are eliminated by pressure-assisted flow in low pressure casting.

For very big parts, sand casting is still popular, but it takes a lot of work to get a good surface finish and accurate measurements. Low pressure casting makes parts with surfaces that are very close to net shapes and have better quality. This cuts down on post-casting work by a large amount.

Investment casting gives you a smooth surface and accurate measurements, but for bigger parts, the cost of the ceramic shell systems makes it impossible. For medium- to large-sized aluminum parts, low pressure casting gives similar quality at much lower prices.

Critical Design Considerations and Challenge Solutions

To use low pressure casting correctly, you need to pay close attention to design rules that make the most of the process's capabilities while avoiding common production mistakes. When engineers know about these things, they can make parts that are of the highest quality while also costing the least to make.

Consistency in wall thickness is very important for getting regular solidification and avoiding flaws. When designers can, they should keep parts as similar as possible while adding gentle changes between widths. This method stops hot spots that can cause finished parts to shrink and become porous.

Gating and releasing devices that work well make sure that the mold fills up correctly and that gas escapes during the casting process. The bottom-gating feature of low pressure casting naturally allows for gradual filling, but careful vent placement keeps air from getting trapped in complicated shapes.

Managing shrinking in heavy parts, stopping cold shuts in thin areas, and keeping the regularity of the surface finish are all common problems. To solve these problems, process parameters like pressure profiles, mold temperatures, and choosing the right metal makeup based on the needs of the product need to be optimized.

Successful uses in car gearbox housings show that careful planning can make it possible to make complicated metal parts that weigh up to 15 kg and have wall thicknesses that range from 3 mm to 25 mm while keeping all the dimensions correct.

Strategic Procurement Guidelines for Low pressure casting Solutions

In order to find effective low pressure casting skills, you need to look at more than just cost. Procurement tactics that work center on the skills of the suppliers, their quality systems, and the chance of building long-term partnerships.

When you evaluate equipment, you should look at how well it controls pressure, how big the boiler is, and how well it can work with automation. Modern systems have real-time tracking and adjustable pressure settings that make sure the quality stays the same from one production run to the next.

Supplier approval and quality control systems show how reliable and compliant a manufacturer is. Basic quality guarantee is provided by ISO 9001 certification, and car suppliers should keep IATF 16949 approval for use in automotive uses. For aerospace uses, you need AS9100 approval and special methods for keeping track of things.

Logistics prices, wait times, and how well people can communicate are all affected by where things are located. Regional providers are helpful for making prototypes and working together on designs, and having long-term ties with them makes it easier to solve problems during the ramp-up phases of production.

The ability to provide technical help is what sets apart providers who offer complete solutions from those who only offer simple manufacturing services. During the whole process of making a product, look for partners who can help with mold creation, metal choice, and process optimization.

Conclusion

Most of the time, low pressure casting is the best way to make big, complicated metal parts for many different businesses. This method produces better quality products because it controls the flow of metal, gets very accurate measurements, and can work with complicated shapes that are hard to cast with other methods. When it comes to automobile, aircraft, and industry uses that need solid performance, low pressure casting is a great choice because it saves material, produces uniform quality, and is cost-effective. Low pressure casting technology provides the framework for meeting these difficult requirements while keeping competitive production costs as manufacturing demands continue to evolve toward lightweight yet durable components.

FAQs

What are the largest sizes that low pressure cast metal parts can be?

Low pressure casting can be used to make parts that are as small as housings that weigh less than 1 kilogram and as big as structural parts that weigh more than 50 kilos. The process works well with complicated shapes and wall thicknesses ranging from 2 mm to 50 mm, so it can be used in a wide range of commercial settings.

In terms of precision, how does low pressure casting stack up against die casting?

Both methods produce very accurate measurements, but low pressure casting is better for bigger parts because it reduces heat stress and allows for more controlled solidification. Tolerances are usually between ±0.1mm and ±0.3mm, based on the shape of the part. This is similar to die casting but doesn't have size limits.

Which types of aluminum work best with low pressure casting?

For structural uses, common metals include A356, A357, and A319, while A380 and A383 are better for general-purpose parts. Which alloy to use depends on how strong it needs to be, how resistant it needs to be to rust, and how easy it needs to be to machine for a given purpose.

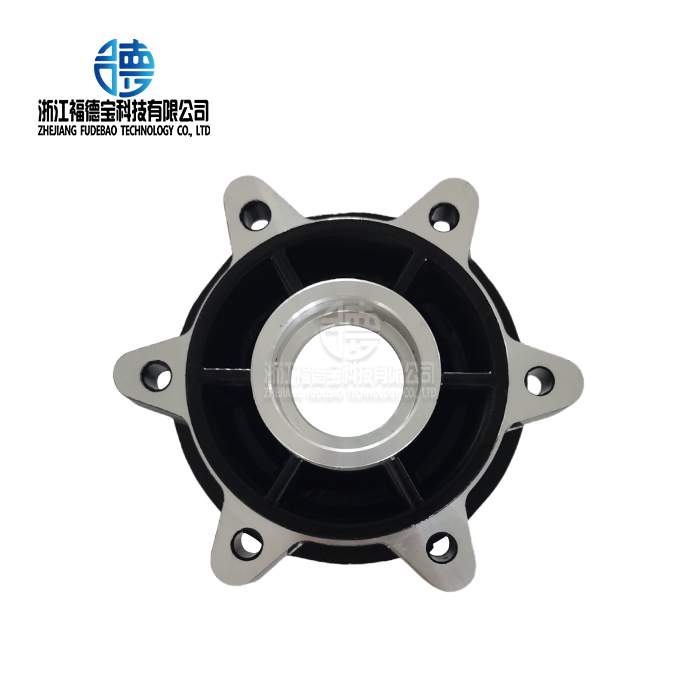

Fudebao Technology: Your Trusted Low pressure casting Manufacturer

Zhejiang Fudebao Technology Co., Ltd. is one of the biggest low pressure casting companies in the world. They make accurate metal parts for the aircraft, automobile, and industrial equipment industries around the world. We have full industrial skills that cover the whole process, from freezing to finishing, and we make sure that quality is checked at every step.

Our building has high-tech low pressure casting machines, high-speed machining centers, and CNC lathes, so we can deliver everything from a blank to a finished product all in one place. This unified method cuts down on wait times while keeping dimensions accurate to within 0.05 mm, meeting the exact needs of precision uses.

Our clients come from a wide range of fields, such as automobile OEMs that need transmission housings and engine parts, industrial equipment manufacturers that need pump housings and machinery brackets, and aerospace companies that need lightweight structure elements. Because we know a lot about making aluminum alloys, we can make sure that the material has the best qualities for each job.

Are you ready to learn more about how low pressure casting can help you make better metal parts? Our technical team can give you full advice on how to improve your design, choose the right metal, and set the right process settings for your needs. Get in touch with us at hank.shen@fdbcasting.com to talk about your project and find out why top makers choose Fudebao Technology for their most important aluminum casting jobs.

_1756348543350.webp)

_1756346310015.webp)

_1756348300182.webp)

_1756348780785.webp)

_1756349862928.webp)

_1756360265131.webp)