Japanese companies that make robots are working with Chinese CNC machining makers more and more because they offer the best mix of low prices, cutting-edge technology, and manufacturing freedom. Precision machining shops in China have high-tech tools, trained workers, and efficient production methods that meet the high standards needed for robotics parts. Japanese businesses can stay ahead of the competition in global markets thanks to their strategic benefits, such as lower costs, access to cutting-edge machinery, quick prototype development, and the ability to produce large batches of goods.

Understanding Precision CNC machining in the Robotics Industry

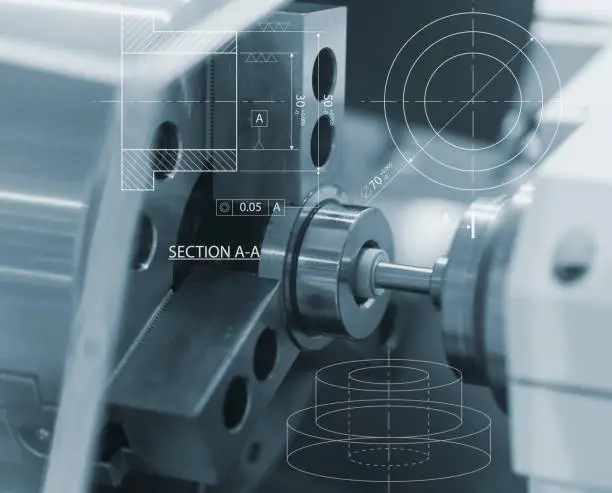

For the robotics business to work, parts must be very precise and reliable. In complicated mechanical systems, every gear, case, bolt, and structure part has to work perfectly. Precision cutting technologies have changed the way these important parts are made because they can do things that older methods of making things just can't.

Computer numerical control systems let companies make parts with margins as small as ±0.001 inches. This makes sure that the quality of thousands of parts is always the same. Modern machining centers have more than one axis of movement, which lets them make complicated shapes with just a few sets. This method cuts down on handling mistakes and keeps the measurements correct throughout the whole production process.

Choosing the right materials is very important in robotics uses. Alloys made of aluminum have great strength-to-weight ratios, but stainless steel is better at resisting rust in tough settings. Copper alloys are great for motor parts and electrical housings because they carry electricity very well. Advanced cutting methods can be used on titanium, Inconel, and other aerospace-grade materials that are very specific.

Surface finishing has come a long way, and now machining centers can get results that look like mirrors without having to do any extra work. These surfaces lower friction, make parts last longer, and meet the strict cleanliness standards needed for precision robots.

Why Japanese Robotics Makers Prefer Chinese Precision CNC machining?

The choice to work with Chinese factories comes from a number of strategic benefits that have a direct effect on how competitive and profitable the business is. Japanese businesses have found that Chinese sellers can offer great deals on CNC machining without lowering the quality of their goods.

One main reason for this relationship trend is the desire to save money. Costs of making things in China are usually 40–60% less than in Japan. This is mostly because of differences in the cost of labor and economies of scale. Japanese robotics businesses can use the money they save to fund research and development, market growth, and methods for setting prices that are competitive.

In the best Chinese factories, technology has hit levels that are on par with the best in the world. In Chinese factories, state-of-the-art machine tools from well-known brands like Haas, Mazak, and DMG Mori are used, which means that the quality is on par with any global production hub. Coordinate measuring tools and laser interferometry are two examples of advanced measurement systems that make sure quality control meets international standards.

Chinese providers have a clear edge when it comes to production freedom. Larger factories tend to focus on high-volume production runs, but many Chinese makers are very good at handling different batch sizes and quick changes. This freedom is very helpful for robots companies that are making new goods or serving niche markets with specific needs.

Integration of the supply chain has gotten a lot better in the last ten years. Chinese companies have put a lot of money into transportation systems, quality control systems, and communication tools that make working with clients from other countries easy. Real-time project tracking, digital quality reports, and the ability to hold video conferences make it possible to handle production projects from afar.

Comparing CNC machining Alternatives in Robotics Manufacturing

When making new goods, robotics companies look at a number of different ways to make them. Different methods have different pros and cons that affect design choices and production methods.

Some types of additive manufacturing, like selective laser sintering and direct metal laser sintering, make it possible to make quick prototypes and parts with complicated internal shapes. These methods work great for small-scale production and testing designs, but they aren't great at giving precision robots parts the right surface finish and dimensions compared to CNC machining. Compared to standard cutting, the choice of materials is still restricted.

With investment casting, you can get both smooth surfaces and complicated forms all in one step. This method works well for both aluminum and steel parts, but it costs a lot to buy the tools needed and takes longer to make the parts. Most of the time, dimensional margins are between ±0.005 and ±0.010 inches, which might not meet the strictest robots requirements.

Electrical discharge cutting is great for making complicated shapes out of solid materials. This method works with standard cutting in certain situations, but it takes longer to make things and costs more per part. When it comes to robots production, EDM is useful for tool and die uses.

Traditional cutting methods give you the most choices when it comes to materials, precision in measurements, and beauty of the finish on the surface. Today's machining centers can keep tolerances to within ±0.0002 inches and keep the surface edges very smooth. Being able to machine different types of materials in the same building makes managing the supply chain easier and makes inventory less complicated.

In China, factories often use combined production methods that blend more than one technology. This method lets makers find the best way to make each part while still keeping quality control and project planning.

Selecting the Right Chinese CNC machining Partner for Japanese Robotics

For agreements to work, possible sellers need to be carefully evaluated based on a number of factors. To make sure they can work together successfully in the long run, Japanese companies must look at each other's expert skills, quality processes, and culture fit.

The review of technical competence starts with an evaluation of the CNC machining tools. Leading suppliers use high-tech machining machines that can do 5-axis simultaneous cutting, have high-speed frames, and have precision workholding systems. Coordinate measuring tools, surface profilometers, and statistical process control systems should all be able to be used for measurements.

Quality management systems show how mature a company is and how committed it is to always getting better. ISO 9001 certification shows basic standards, while AS9100 or TS 16949 certifications show more advanced quality management skills. Suppliers should show that they have strong controls over documents, methods for taking appropriate action, and procedures for qualifying themselves as suppliers.

As projects get harder, being able to communicate clearly has become more and more important. Suppliers should offer expert help in English, project management tools, and regular updates on progress. Videoconferencing lets people talk to each other face-to-face, which helps build relationships and quickly solve technology problems.

The most accurate way to judge a supplier's skills is to look at a sample part. Requesting parts with difficult features, tight standards, and important surface finishes shows what the real production capabilities are, not what the marketing claims are. Dimensional records, material approvals, and measures of the surface finish all give independent opinions on quality.

Stable finances and plans for capacity make sure that providers can support business relationships that are growing. Established sellers with a wide range of customers and various sites for their facilities offer more security and the ability to grow as partnerships grow.

Conclusion

Japanese robotics companies have found that working with Chinese precise machine sources has a lot of benefits. Advanced technical skills, cost-effective production, and flexible CNC machining methods give companies big benefits in the market. As the robotics industry grows, these smart relationships will become even more important for staying ahead of the competition and fostering new ideas. To work together well, you need to be careful when choosing your suppliers, communicate clearly, and all share a dedication to quality excellence.

FAQs

What kinds of materials can Chinese precise machine shops work with when making robots?

Some of the best factories in China work with a wide range of materials, such as aluminum alloys (6061 and 7075), stainless steel grades (304, 316, and 17-4 PH), copper alloys, titanium, and industrial plastics. The choice of material is based on the needs of the product, such as strength, resistance to rust, electrical conductivity, and weight.

How do the limits for milling in China relate to those used around the world for robots parts?

Chinese factories that are very advanced keep their cutting margins between ±0.0002 and ±0.002 inches, which is the same as or better than international standards for precision robots parts. Coordinate measure tools and statistical process control systems to make sure that the quality of each production run is the same.

What kind of quality standards should I look for in Chinese providers of precise machining?

As a minimum, reputable providers must have ISO 9001 quality control approval. A lot of facilities also have approvals specific to their fields, like AS9100 for aircraft uses or TS 16949 for car parts. Getting these certificates shows that you are dedicated to organized quality management and always making things better.

Partner with Fudebao Technology for Superior CNC machining Solutions

Zhejiang Fudebao Technology Co., Ltd. is one of the best CNC machining companies in the world, and they serve the robotics business with great accuracy and dependability. Our wide range of production skills includes working with aluminum alloys, copper alloys, and stainless steel. We can make parts that meet the strictest requirements for use in cars, factories, and spacecraft.

Our building has state-of-the-art machinery, like high-speed machining centers, advanced CNC lathes, and casting systems that are all built in. This machinery helps us provide full manufacturing solutions. When heating, casting, finishing, and surface treatment are all done at the same time, raw materials can be delivered to final parts all at once. With precision levels as low as ±0.05mm, parts are made to meet the exact needs of robots applications.

Every part of our business is driven by quality greatness. Our team uses strict process controls and thorough testing methods to make sure that the results are the same from one production run to the next. For important uses, material certificates, measurement records, and documents on the surface finish make it possible to fully track the materials used.

Customer relationships include more than just manufacturing. They also include design improvement, cost reduction research, and help with managing the supply chain. Our technical team works closely with clients to find ways to make products easier to make and better at what they do.

Japanese robotics companies looking for a reliable CNC machining source will find that our wide range of skills and dedication to excellence make us a great choice. Email us at hank.shen@fdbcasting.com to talk about your unique needs and find out how our precision manufacturing services can help you stay ahead of the competition.

_1756346371362.webp)

_1756348356531.webp)

_1756349071334.webp)

_1756352822273.webp)

_1756361494985.webp)