OEMs around the world are increasingly choosing aluminum die casting for lightweight parts because it has the best strength-to-weight ratios, the most accurate dimensions, and the highest production efficiency. In today's world, businesses like automobile, aircraft, and industrial need parts that keep the structure of the product intact while reducing its total weight. These needs can be met by aluminum die casting, which makes complicated shapes with little post-processing. This lets makers meet weight reduction goals without lowering performance or sturdiness standards.

Understanding Aluminum die casting and Its Process

When high-pressure aluminum metals are injected into steel dies, they are cooled and then shaped into exact, complicated parts. This is called the aluminum die casting process. This method is very different from regular sand casting or investment casting. It allows for better control of dimensions and faster production processes.

Aluminum alloys are heated to about 1,300°F and then poured into steel molds that have been specially made under pressures ranging from 1,500 to 25,400 PSI. The fast cooling and solidification make parts with a smooth surface and tight tolerances, which often means that they don't need to be machined again. Modern die casting machines have automatic systems that make sure the quality is always the same and cut down on run times.

Because this process is so flexible, it lets makers make complicated shapes with thin walls, complicated internal spaces, and built-in features that would be impossible or too expensive to make any other way. High-pressure die casting is the best way to make lightweight metal parts with great mechanical qualities. This is why it is the best choice for weight-sensitive uses in many industries.

Comparative Analysis: Aluminum die casting vs Alternative Methods

Thinking about different ways to make lightweight parts, aluminum die casting stands out as being clearly better than other choices. Knowing the differences between these terms helps engineering teams make smart choices about how to make parts.

Aluminum die casting has a better surface finish than sand casting, reaching Ra values of 1.6 to 3.2 micrometers without any extra work. For similar precision and surface quality, sand casting usually needs a lot of grinding. Die casting can achieve tolerances of ±0.05mm in terms of size, while sand casting can usually reach tolerances of ±0.5mm.

Compared to zinc and magnesium, which are also used for die casting, aluminum is better at resisting rust and keeping heat in. At temperatures up to 300°C, aluminum parts keep their shape, but zinc metals start to lose their power at lower temps. The strength-to-weight ratio of aluminum alloys A380 and A356 is better than that of magnesium and zinc in most construction situations.

Aluminum die cast parts are better at transferring heat and supporting weight than plastic injection molding parts. While plastics give designers more freedom in how they make things, metal parts have important properties like electromagnetic protection, heat cooling, and the power needed for tough jobs.

Design and Quality Considerations for Aluminum die casting

To make aluminum die casting work, you need to pay close attention to design rules that improve both the performance of the parts and the speed of the manufacturing process. When you use the right design strategies, you can avoid common flaws and get the most out of the lightweight benefits of aluminum alloys.

Uniform wall thickness is a very important part of getting good results. The best wall thickness is between 1.5 mm and 6 mm, with smooth changes between widths to avoid problems caused by flow. Instead of sharp corners, you should use curves of at least 0.5 mm to make the material move better and spread out stress better.

Draft angles between 0.5° and 2° make it easy to remove parts in aluminum die casting while keeping their dimensions correct. With moving cores, undercuts and complicated internal features can be made, but this increases the cost of tools and cycle times. If they are the right width ratios, ribs and bosses make structures stronger without adding a lot of weight.

As part of quality control, the injection pressure, temperature profiles, and cooling rates are watched in real time. Coordinate measuring machines (CMM) and computed tomography are two advanced checking methods that make sure that dimensions are met. Surface treatments like anodizing, powder coating, or chemical conversion coats make things look better and make them less likely to rust.

Applications and Industry Use Cases of Aluminum die casting

In order to meet strict fuel economy and pollution standards, the car industry is the biggest buyer of aluminum die cast parts. Aluminum housings, braces, and structural parts that are light directly help to lighten vehicles while still meeting safety standards.

Aluminum's ability to conduct heat and its light weight are very helpful for engine parts. Die casting is used to make transmission housings, oil pans, and cylinder heads. These parts make the engine lighter and better at getting rid of heat. These parts meet the PPAP paperwork standards and car quality standards that are needed to work with tier-1 suppliers.

The best strength-to-weight ratios are needed in aerospace uses, which is where aluminum die casting comes in handy. Avionics housings, structural frames, and control system parts must meet strict approval standards while keeping weight losses to a minimum, which can affect how much fuel an airplane uses and how much it can carry.

For pump housings, motor frames, and heat exchanges, makers of industrial tools use aluminum die casting. Aluminum metals have qualities that make them resistant to rust and heat, which means that equipment lasts longer and needs less upkeep. Aluminum's ability to carry electricity makes it useful for motor housings, electrical covers, and heat sink parts in the electrical and energy sectors.

Procurement Insights and Supplier Selection for Aluminum die casting

When buying aluminum die casting services strategically, you need to look at the skills, quality systems, and production facilities of each provider in great detail. For agreements to work, partners must choose makers who have a track record of making lightweight parts.

Different industries have different certification needs, but ISO 9001 quality control systems are the most basic requirement for providers you can trust. For automotive uses, you need IATF 16949 approval, and for aircraft uses, you need AS9100 compliance. Environmental approvals, such as RoHS and REACH compliance, make sure that rules are followed.

Prototyping lets you quickly test and improve designs many times before you invest in production tools. Suppliers who offer combined services from developing prototypes to mass production make it easier to control the supply chain and lower the pressure to get products to market faster.

Lead times, transportation prices, and the ease of contact are all affected by where something is located. Local suppliers are better for making prototypes and working together on designs, while global suppliers may be cheaper for making a lot of things. For a supply chain to be resilient, strategies for reducing risk must be balanced with strategies for lowering costs.

Investing in tools is an important part of buying things, and dies can cost anywhere from $10,000 to $100,000, based on how complicated the part is. When you spread the cost of tools out over a large amount of production, unit prices and minimum order numbers change. Demand variability management works better with suppliers who offer open number promises.

Conclusion

Global original equipment manufacturers (OEMs) choose aluminum die casting for lightweight parts because it reduces weight, improves structural performance, and speeds up production. Aluminum die casting is essential for modern manufacturing across automobile, aircraft, and industrial uses due to its better strength-to-weight ratios, measurement correctness, and design freedom. As long as industries put a high priority on reducing weight and improving performance, aluminum die casting will remain the best way to make lightweight parts that meet strict technical requirements and stay cost-effective when mass-produced.

FAQs

What kinds of aluminum metals are best for die making lightweight objects?

The best performance for lightweight uses comes from aluminum alloys A380 and A356. The A380 has great flexibility and strength, making it perfect for complex shapes. The A356, on the other hand, has better strength-to-weight ratios and is better at keeping pressure out of structural parts.

Which is better for weight reduction: cutting from solid billets or aluminum die casting?

Die casting makes nearly net-shape parts with very little waste, using 90–95% of the material, while made parts only use 20–30%. This efficiency cuts down on both weight and cost while making it possible to make complex internal shapes that couldn't be done with cutting alone.

What is the lowest amount of metal die cast parts that you can order?

For first production runs, the minimum order numbers are usually between 500 and 5,000 pieces, but this depends on the complexity of the part and the cost of the tools. For equipment investments to be worthwhile and prices to be reasonable, mass production needs to make 10,000 or more pieces per year.

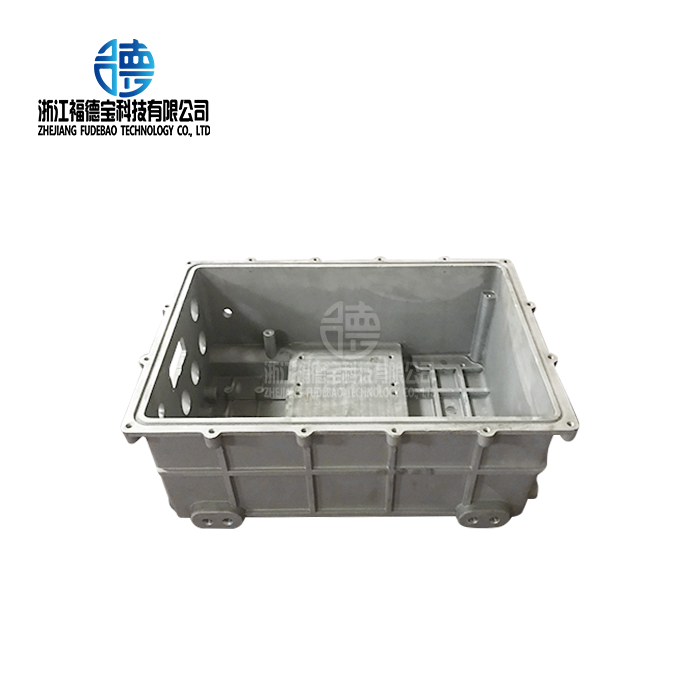

Partner with Fudebao Technology for Premium Aluminum die casting Solutions

As a top aluminum die casting company, Zhejiang Fudebao Technology Co., Ltd. makes precise, lightweight parts for OEMs around the world in the automobile, aircraft, and industrial sectors. Our full manufacturing services cover the whole production cycle, from melting and casting to finishing and surface treatment, so we can meet all of your shipping needs in one place.

Our high-tech building has CNC lathes, high-speed machining centers, low-pressure casting machines, and precision die casting tools that can hold parts to within ±0.05mm of the true size. This level of accuracy meets the strict needs of precision parts for cars, medical gadget cases, and aircraft parts. We offer scalable manufacturing solutions that are suited to your unique needs for lightweight components, from making prototypes to mass production.

The combined method gets rid of the complexity of the supply chain and keeps the quality of the product consistent throughout production. Our quality control systems make sure that we follow foreign standards and meet the PPAP paperwork and approval needs that are necessary for OEM agreements. Are you ready to improve the way you make lightweight parts by working with a reliable aluminum die casting supplier? Email us at hank.shen@fdbcasting.com for expert advice and unique solutions that will help your business grow.

References

North American Die Casting Association. "Aluminum Die Casting Design Guidelines and Best Practices." Technical Publication Series, 2023.

Society of Automotive Engineers. "Lightweight Materials in Automotive Applications: Aluminum Die Casting Advancements." SAE International Journal of Materials and Manufacturing, Vol. 16, 2023.

American Foundry Society. "Comparative Analysis of Metal Casting Processes for Lightweight Component Manufacturing." Modern Casting Magazine, December 2022.

Aluminum Association. "Aluminum Die Casting in Transportation Applications: Market Trends and Technology Developments." Industry Report, 2023.

International Journal of Advanced Manufacturing Technology. "Process Optimization in High-Pressure Aluminum Die Casting for Lightweight Structural Components." Springer Publications, 2022.

ASM International. "Aluminum and Aluminum Alloys: Properties and Applications in Die Casting." Materials Handbook Series, 15th Edition, 2023.

_1756346144394.webp)

_1756348227989.webp)

_1756349794241.webp)

_1756352561845.webp)