Understanding CNC Machining and 3D Printing Technologies

CNC Machining: Precision Through Subtractive Manufacturing

CNC machining is a subtractive manufacturing process that uses computer-controlled tools to remove material from a solid block, creating precise parts with excellent surface finishes. This technology offers unparalleled accuracy, with tolerances as tight as ±0.05mm, making it ideal for producing prototypes that require high precision and functionality.

The process begins with a 3D CAD model, which is translated into a series of tool paths. These instructions guide the CNC machine's cutting tools to shape the workpiece into the desired form. CNC machining can work with a wide range of materials, including metals like aluminum alloys, copper alloys, and stainless steel, as well as plastics and composites.

One of the key advantages of CNC machining for prototyping is its ability to produce parts that closely resemble final production components in terms of material properties and performance. This makes CNC-machined prototypes excellent for functional testing and validation before moving to full-scale production.

3D Printing: Additive Manufacturing for Complex Geometries

3D printing, also known as additive manufacturing, builds parts layer by layer from a digital 3D model. This technology has revolutionized the prototyping landscape by enabling the creation of complex geometries that would be difficult or impossible to achieve with traditional manufacturing methods.

There are several 3D printing technologies available, including Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS). Each of these methods has its own strengths and limitations in terms of material options, resolution, and surface finish.

3D printing excels in producing prototypes quickly and cost-effectively, especially for small batches or one-off parts. It allows for rapid iteration of designs, making it an invaluable tool in the early stages of product development when frequent changes are common.

Material Considerations: Versatility vs. Specialization

When comparing CNC machining and 3D printing for prototyping, material selection plays a crucial role. CNC machining offers a broader range of material options, including metals, plastics, and composites, which can closely match the properties of final production materials. This versatility is particularly important for prototypes that need to undergo rigorous testing or simulate real-world conditions.

3D printing, while more limited in material choices, has seen significant advancements in recent years. Specialized 3D printing materials now include high-performance polymers, metal powders, and even biocompatible materials for medical applications. However, the mechanical properties of 3D printed parts may differ from those produced by traditional manufacturing methods, which can be a consideration for functional prototypes.

Comparing the Pros and Cons for Prototyping

Advantages of CNC Machining in Prototyping

CNC machining offers several distinct advantages for prototyping:

- Precision: Achieves tight tolerances and excellent surface finishes, crucial for parts that require high accuracy.

- Material Variety: Works with a wide range of materials, including metals and high-performance plastics, allowing for prototypes that closely match final production materials.

- Strength and Durability: Produces parts with consistent material properties throughout, ideal for functional testing.

- Scalability: Easily transitions from prototyping to low-volume production without significant changes in the manufacturing process.

These benefits make CNC machining particularly suitable for industries such as automotive, aerospace, and medical device manufacturing, where precision and material properties are critical.

Limitations of CNC Machining for Prototypes

Despite its advantages, CNC machining has some drawbacks in the prototyping phase:

- Setup Time: Initial programming and setup can be time-consuming, especially for complex geometries.

- Cost for Small Batches: May be less cost-effective for very small quantities or one-off prototypes.

- Geometric Limitations: Some complex internal features or organic shapes can be challenging or impossible to machine.

- Material Waste: As a subtractive process, it generates more material waste compared to additive manufacturing.

Benefits of 3D Printing in Prototype Development

3D printing brings its own set of advantages to prototyping:

- Design Freedom: Allows for the creation of complex geometries and internal structures that would be difficult to achieve with traditional manufacturing methods.

- Rapid Iteration: Enables quick design changes and fast turnaround times for prototype production.

- Cost-Effective for Small Batches: Ideal for producing small quantities or one-off prototypes without the need for tooling.

- Reduced Material Waste: Additive process uses only the material needed for the part, minimizing waste.

These characteristics make 3D printing particularly valuable in the early stages of product development and for industries that require frequent design iterations or customized products.

Making the Right Choice for Your Prototyping Needs

Factors to Consider When Choosing Between CNC and 3D Printing

Selecting the appropriate prototyping method depends on several factors:

- Material Requirements: Consider the mechanical and thermal properties needed for your prototype.

- Geometric Complexity: Evaluate the intricacy of your design and whether it's better suited for additive or subtractive manufacturing.

- Production Volume: Determine if you need a single prototype or multiple iterations.

- Time Constraints: Assess your project timeline and how quickly you need the prototype.

- Budget: Compare the costs of CNC machining versus 3D printing for your specific project.

- Functional Testing: Decide if the prototype needs to undergo rigorous testing that simulates real-world conditions.

By carefully evaluating these factors, manufacturers can make informed decisions that optimize their prototyping process and lead to better final products.

Hybrid Approaches: Combining CNC Machining and 3D Printing

In many cases, the most effective prototyping strategy involves a combination of CNC machining and 3D printing. This hybrid approach leverages the strengths of both technologies to create optimal prototypes. For example:

- Using 3D printing for rapid concept validation and initial design iterations.

- Employing CNC machining for functional prototypes that require precise tolerances and specific material properties.

- Combining 3D printed components with CNC machined parts to create complex assemblies.

This synergistic approach allows manufacturers to balance speed, cost, and functionality throughout the prototyping process.

Future Trends in Prototyping Technologies

As manufacturing technologies continue to evolve, we can expect to see advancements that further enhance prototyping capabilities:

- Improved 3D printing materials with properties closer to traditional manufacturing materials.

- Enhanced CNC machining software for more efficient programming and reduced setup times.

- Integration of artificial intelligence to optimize prototyping processes and material selection.

- Development of new hybrid manufacturing technologies that combine additive and subtractive processes in a single machine.

Staying informed about these trends will help manufacturers make the most of emerging technologies and maintain a competitive edge in product development.

Conclusion

Both CNC machining and 3D printing offer valuable solutions for prototyping, each with its own set of advantages and limitations. CNC machining excels in precision, material versatility, and producing functional parts, making it ideal for prototypes that require high accuracy and real-world testing. 3D printing, on the other hand, shines in rapid iteration, complex geometries, and cost-effectiveness for small batches, making it perfect for early-stage design validation and customization. The choice between these technologies depends on specific project requirements, including material needs, design complexity, production volume, and time constraints. By understanding the strengths of each method and considering hybrid approaches, manufacturers can optimize their prototyping processes and accelerate product development.

FAQs

Which is more cost-effective for prototyping, CNC machining or 3D printing?

The cost-effectiveness depends on factors like quantity, material, and complexity. 3D printing is often more economical for small batches or complex geometries, while CNC machining can be more cost-effective for larger quantities or when specific materials are required.

Can CNC machining produce the same complex geometries as 3D printing?

While CNC machining is highly precise, it has limitations with certain complex internal features. 3D printing generally offers more freedom in creating intricate geometries.

How do the material properties of CNC machined parts compare to 3D printed ones?

CNC machined parts typically have more consistent and predictable material properties, closely matching those of the raw material. 3D printed parts may have anisotropic properties due to the layer-by-layer build process.

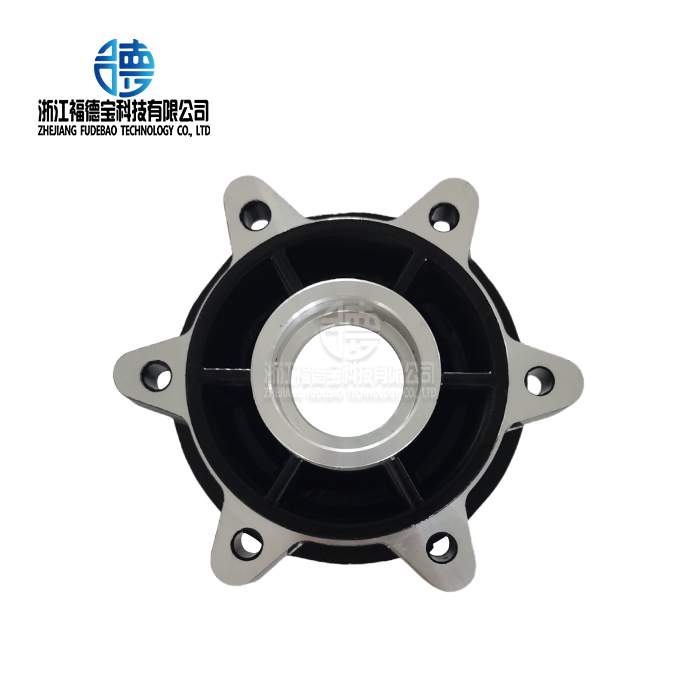

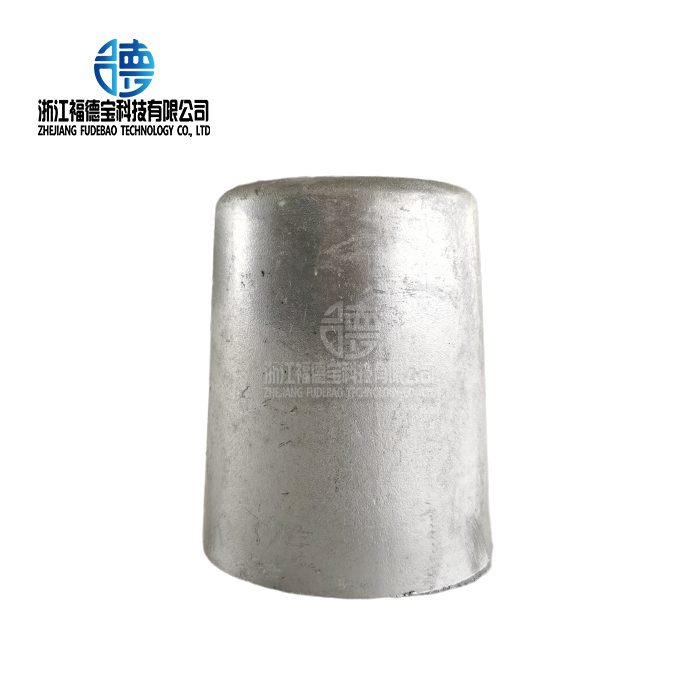

Expert CNC Machining Services for Prototyping | Fudebao Technology

At Fudebao Technology, we specialize in high-precision CNC machining for prototyping and production. Our state-of-the-art facility is equipped with advanced CNC machining centers and lathes, capable of working with a wide range of materials including aluminum alloys, copper alloys, and stainless steel. We offer comprehensive services from prototype to finished product, with accuracies up to ±0.05mm. As a leading CNC machining supplier and manufacturer, we cater to diverse industries including automotive, industrial equipment, and medical devices. Contact us at hank.shen@fdbcasting.com to learn how our expertise can benefit your prototyping needs.

References

Smith, J. (2022). Advanced Manufacturing Technologies: CNC Machining and 3D Printing Compared. Journal of Manufacturing Engineering, 45(3), 112-128.

Johnson, A., & Brown, L. (2021). Prototyping Strategies in Modern Product Development. International Journal of Industrial Design, 18(2), 78-95.

Lee, K., et al. (2023). Material Considerations in Additive and Subtractive Manufacturing for Prototyping. Materials Science and Engineering: A, 832, 142357.

Thompson, M. K., et al. (2022). Design for Additive Manufacturing: Trends, Opportunities, Considerations, and Constraints. CIRP Annals, 71(2), 728-751.

Chen, Y., & Wang, L. (2021). Hybrid Manufacturing: Integrating CNC Machining and 3D Printing for Optimal Prototyping. Rapid Prototyping Journal, 27(4), 712-725.

Garcia, R., et al. (2023). Cost Analysis of Prototyping Methods: A Comparative Study of CNC Machining and Additive Manufacturing. Journal of Manufacturing Processes, 85, 293-308.

_1756346205762.webp)

_1756348356531.webp)

_1756352822273.webp)

_1756361423150.webp)