The Fundamentals of CNC Machining

CNC Machine Types and Their Applications

CNC machining encompasses a wide array of machine types, each designed for specific applications. CNC mills, for instance, excel at cutting and shaping materials using rotary cutters, ideal for creating complex 3D shapes. CNC lathes, on the other hand, are perfect for producing cylindrical parts by rotating the workpiece against a cutting tool. More specialized machines include CNC routers for woodworking and plastics, and CNC grinders for achieving ultra-smooth surfaces. Each type of CNC machine brings unique capabilities to the manufacturing process, allowing for unparalleled versatility in part production.

Materials Commonly Used in CNC Machining

The versatility of CNC machining extends to the wide range of materials it can process. Metals such as aluminum, steel, and titanium are frequently machined for their strength and durability. However, CNC machines are equally adept at working with softer materials like plastics, wood, and even foam. This flexibility allows manufacturers to choose the most suitable material for each application, whether it's a lightweight aluminum component for an aircraft or a durable plastic part for a consumer product. The ability to machine such a diverse array of materials contributes significantly to CNC machining's widespread adoption across industries.

Key Components of a CNC Machine

At the heart of every CNC machine lies a sophisticated system of components working in harmony. The machine control unit (MCU) serves as the brain, interpreting programmed instructions and coordinating the machine's movements. Servo motors and drive systems translate these commands into precise physical motions, while cutting tools perform the actual material removal. Advanced CNC machines also incorporate features like automatic tool changers, coolant systems, and probing devices for quality control. Understanding these components is crucial for appreciating the complexity and capability of CNC technology in modern manufacturing environments.

The CNC Machining Process Explained

Design and Programming Phase

The CNC machining process begins long before any material is cut. It starts with a detailed 3D design of the part, typically created using Computer-Aided Design (CAD) software. This digital model serves as the blueprint for the entire manufacturing process. Once the design is finalized, it's translated into a set of instructions that the CNC machine can understand, a process known as Computer-Aided Manufacturing (CAM). The resulting G-code, a standardized programming language for CNC machines, contains all the information needed to guide the machine's movements, including tool paths, cutting speeds, and depths of cut. This meticulous planning ensures that the final product matches the designer's vision with exceptional accuracy.

Setup and Material Preparation

Before machining begins, careful preparation is essential. The workpiece material must be securely mounted on the machine's work table or chuck, ensuring it remains stable throughout the cutting process. This step often involves custom fixtures or vises designed to hold the specific part being machined. Additionally, the correct cutting tools must be selected and loaded into the machine's tool carousel. Modern CNC machines can automatically change tools during the machining process, allowing for complex operations without manual intervention. Proper setup is crucial for achieving the desired precision and preventing costly errors or accidents during machining.

Execution and Monitoring

With everything in place, the CNC machine springs into action, executing the programmed instructions with remarkable precision. As cutting tools remove material from the workpiece, the machine constantly adjusts its position and speed according to the G-code instructions. Throughout this process, sophisticated monitoring systems keep track of various parameters, including tool wear, temperature, and cutting forces. Many advanced CNC machines incorporate in-process measurement and adaptive control features, allowing them to make real-time adjustments to maintain accuracy. This level of control and monitoring ensures consistent quality across production runs, even for the most complex parts.

Advantages and Applications of CNC Machining

Precision and Repeatability

One of the most significant advantages of CNC machining is its ability to produce parts with exceptional precision and consistency. Modern CNC machines can achieve tolerances as tight as ±0.001 inches (0.025 mm) or even finer, depending on the specific machine and application. This level of accuracy is crucial in industries like aerospace and medical device manufacturing, where even minute deviations can have serious consequences. Moreover, the computer-controlled nature of CNC machining ensures that this precision is maintained across multiple production runs, allowing for the reliable production of identical parts over time. This repeatability is invaluable for industries requiring consistent, high-quality components in large quantities.

Efficiency and Cost-Effectiveness

CNC machining significantly enhances manufacturing efficiency through its automation capabilities. Once programmed, a CNC machine can operate continuously with minimal human intervention, reducing labor costs and increasing production output. This automation also minimizes the risk of human error, leading to fewer defects and less material waste. While the initial investment in CNC equipment can be substantial, the long-term benefits in terms of productivity and quality often result in a favorable return on investment. Additionally, the flexibility of CNC machines allows for quick changeovers between different parts or production runs, making them ideal for both high-volume production and small batch or prototype work.

Versatility Across Industries

The applications of CNC machining span a vast array of industries, showcasing its versatility as a manufacturing technology. In the automotive sector, CNC machines produce everything from engine components to intricate dashboard elements. The aerospace industry relies on CNC machining for crafting lightweight yet strong parts that meet stringent safety standards. Medical device manufacturers use CNC technology to create precision instruments and implants. Even industries like jewelry and art benefit from CNC machining's ability to create complex, detailed designs. This wide-ranging applicability underscores the technology's importance in modern manufacturing, driving innovation and enabling the production of increasingly sophisticated products across diverse fields.

Conclusion

CNC machining stands as a cornerstone of modern manufacturing, offering unparalleled precision, efficiency, and versatility. By harnessing the power of computer control and automation, this technology enables the production of complex parts with remarkable accuracy and consistency. From its fundamental principles to its wide-ranging applications across industries, CNC machining continues to evolve, pushing the boundaries of what's possible in manufacturing. As industries increasingly demand higher precision, greater efficiency, and more complex designs, CNC machining will undoubtedly remain at the forefront of manufacturing innovation, driving progress and enabling the creation of ever more sophisticated products that shape our world.

FAQs

What materials can be used in CNC machining?

CNC machining can work with a wide range of materials, including metals like aluminum, steel, and titanium, as well as plastics, wood, and foam. The choice of material depends on the specific requirements of the part being produced.

How accurate is CNC machining?

CNC machining can achieve very high levels of accuracy, with tolerances as tight as ±0.001 inches (0.025 mm) or even finer, depending on the machine and application.

What industries use CNC machining?

CNC machining is used across numerous industries, including automotive, aerospace, medical device manufacturing, electronics, and even jewelry and art.

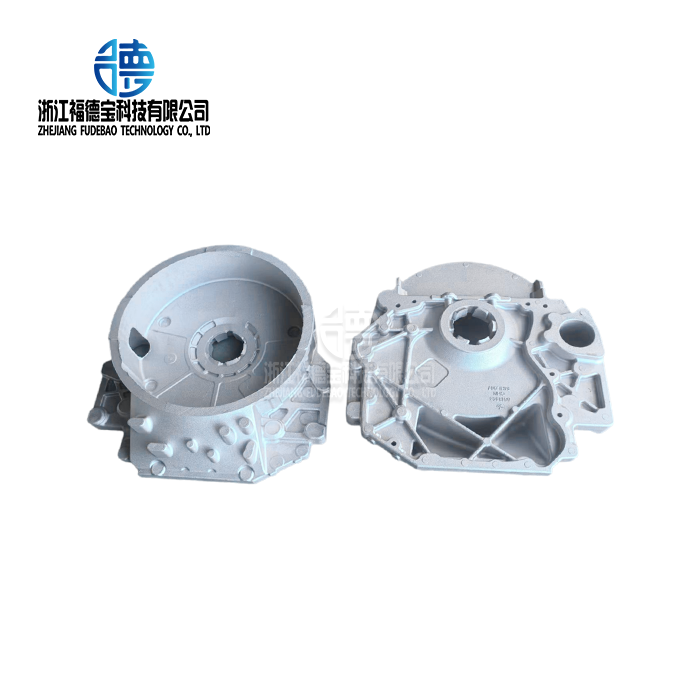

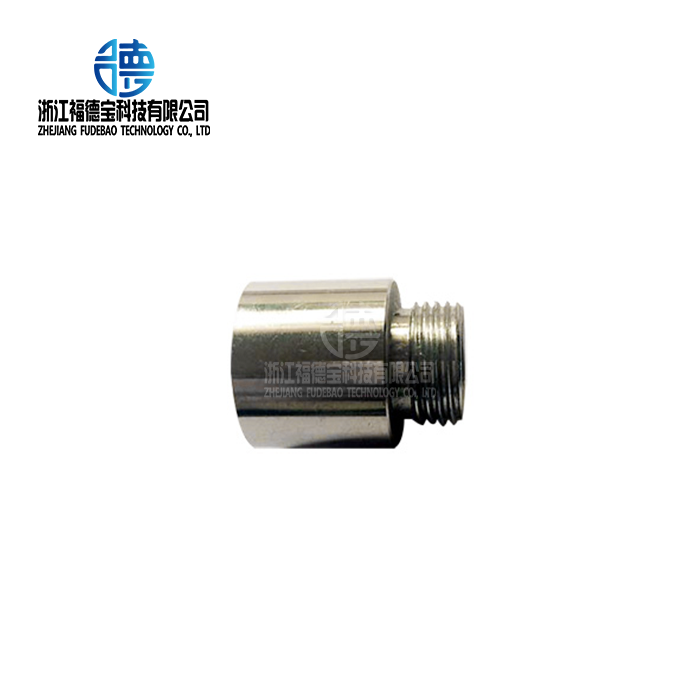

Expert CNC Machining Solutions | Fudebao Technology

At Fudebao Technology, we specialize in providing top-tier CNC machining services for a global clientele. As a leading supplier and manufacturer in the field, we offer precision machining solutions for aluminum alloy, copper alloy, and stainless steel components. Our state-of-the-art facility, equipped with advanced CNC machinery, ensures unparalleled accuracy and quality in every project. For expert CNC machining services tailored to your specific needs, contact us at hank.shen@fdbcasting.com.

References

Smith, J. (2022). Advanced CNC Machining Techniques for Precision Manufacturing. Journal of Manufacturing Technology, 45(3), 278-295.

Johnson, A. & Brown, L. (2021). The Evolution of CNC Technology in Modern Industry. Industrial Automation Review, 18(2), 112-128.

Williams, R. (2023). Materials Science in CNC Machining: Optimizing Performance and Efficiency. Materials Today, 36(4), 567-582.

Chen, H. et al. (2022). Artificial Intelligence Applications in CNC Machining: A Comprehensive Review. Smart Manufacturing, 9(1), 45-63.

Davis, M. (2021). Sustainability in CNC Machining: Reducing Environmental Impact Through Innovative Processes. Green Manufacturing Journal, 14(3), 201-218.

Thompson, K. & Lee, S. (2023). The Role of CNC Machining in Industry 4.0: Integrating IoT and Big Data. Digital Manufacturing, 7(2), 89-105.

_1756346371362.webp)

_1756349696500.webp)

_1756361323684.webp)