Understanding CNC Machining Materials

Properties of CNC Machining Materials

CNC machining materials are characterized by various properties that influence their suitability for different applications. These properties include strength, durability, machinability, and cost-effectiveness. For instance, aluminum offers an excellent strength-to-weight ratio, making it ideal for lightweight components. Brass, on the other hand, provides superior machinability and corrosion resistance. Steel stands out for its exceptional strength and heat resistance, while plastics offer versatility and chemical resistance.

Factors Influencing Material Selection

Selecting the right material for CNC machining involves considering several factors. These include the intended application of the part, environmental conditions it will be exposed to, budget constraints, and production volume. For example, if you're manufacturing parts for outdoor use, you might prioritize materials with high corrosion resistance like stainless steel or certain grades of aluminum. Similarly, for high-volume production, materials with good machinability like brass or certain plastics might be preferred to reduce machining time and costs.

Impact of Material Choice on CNC Machining Process

The choice of material significantly impacts the CNC machining process. Different materials require specific cutting tools, speeds, and feeds to achieve optimal results. For instance, aluminum can be machined at higher speeds compared to steel, potentially reducing production time. Plastics, while generally easier to machine, may require special considerations to prevent melting or deformation during the process. Understanding these nuances is crucial for efficient and high-quality CNC machining.

Detailed Analysis of CNC Machining Materials

Aluminum: The Lightweight Champion

Aluminum is a popular choice for CNC machined parts due to its excellent strength-to-weight ratio. It's widely used in aerospace, automotive, and consumer electronics industries. Aluminum is easy to machine, allowing for complex geometries and fine details. It also offers good corrosion resistance and thermal conductivity. Common aluminum alloys for CNC machining include 6061-T6 and 7075-T6, each offering different combinations of strength and machinability.

Brass: Combining Beauty and Functionality

Brass is renowned for its excellent machinability and aesthetic appeal. It's often used for decorative parts, electrical components, and plumbing fixtures. Brass has good corrosion resistance and can be polished to a high shine. Its malleability allows for intricate designs, making it popular for custom parts. However, brass can be more expensive than some other materials and may not be suitable for high-stress applications.

Steel: Strength and Versatility

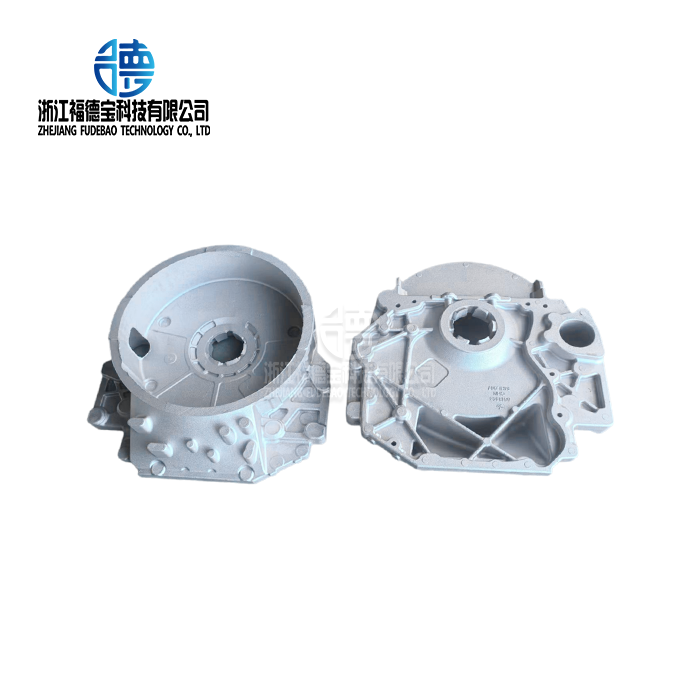

Steel is the go-to material when strength and durability are paramount. It's used extensively in heavy machinery, construction, and automotive industries. Steel comes in various grades, from low-carbon steels that are easier to machine to high-carbon and alloy steels that offer enhanced properties. Stainless steel, a corrosion-resistant variant, is popular for parts exposed to harsh environments. While steel can be more challenging to machine than softer materials, modern CNC machines and cutting tools have made steel machining more efficient.

Emerging Trends in CNC Machining Materials

Advanced Plastics in CNC Machining

Plastics have become increasingly popular in CNC machining due to their versatility and cost-effectiveness. High-performance plastics like PEEK (Polyether Ether Ketone) and PEI (Polyetherimide) offer exceptional strength, heat resistance, and chemical resistance, rivaling some metals in certain applications. These advanced plastics are finding use in aerospace, medical, and automotive industries. Their low weight and ability to be machined into complex shapes make them ideal for prototyping and low-volume production runs.

Composite Materials: The Future of CNC Machining?

Composite materials, such as carbon fiber reinforced plastics (CFRP), are gaining traction in CNC machining. These materials offer an excellent combination of strength and light weight, making them attractive for aerospace and high-performance automotive applications. While machining composites can be challenging due to their anisotropic properties, advancements in cutting tool technology and machining strategies are making it more feasible. As these materials become more prevalent, we can expect to see more CNC machined parts made from composites in the future.

Sustainable Materials in CNC Machining

With growing environmental concerns, there's an increasing focus on sustainable materials in CNC machining. This includes recycled metals, biodegradable plastics, and materials derived from renewable sources. For instance, some companies are experimenting with CNC machining of wood-plastic composites, which combine the aesthetics of wood with the durability of plastic. While these materials may have limitations in terms of strength or machinability compared to traditional options, they offer environmental benefits that are becoming increasingly important to many industries.

Conclusion

Choosing the best material for CNC machined parts requires a careful consideration of various factors including the part's intended use, required properties, and budget constraints. While traditional materials like aluminum, brass, steel, and plastic continue to dominate the field, emerging trends in advanced plastics, composites, and sustainable materials are expanding the possibilities of CNC machining. As technology continues to evolve, we can expect to see even more innovative materials and machining techniques that push the boundaries of what's possible in precision manufacturing.

FAQs

What is the most commonly used material in CNC machining?

Aluminum is one of the most commonly used materials due to its versatility and ease of machining.

Can CNC machines work with hardened steel?

Yes, modern CNC machines can work with hardened steel, but it requires specialized cutting tools and techniques.

Are there any materials that cannot be CNC machined?

While most materials can be CNC machined, some extremely hard or brittle materials may pose challenges.

How does material choice affect the cost of CNC machining?

Material choice significantly impacts cost, with factors like material price, machinability, and tool wear all playing a role.

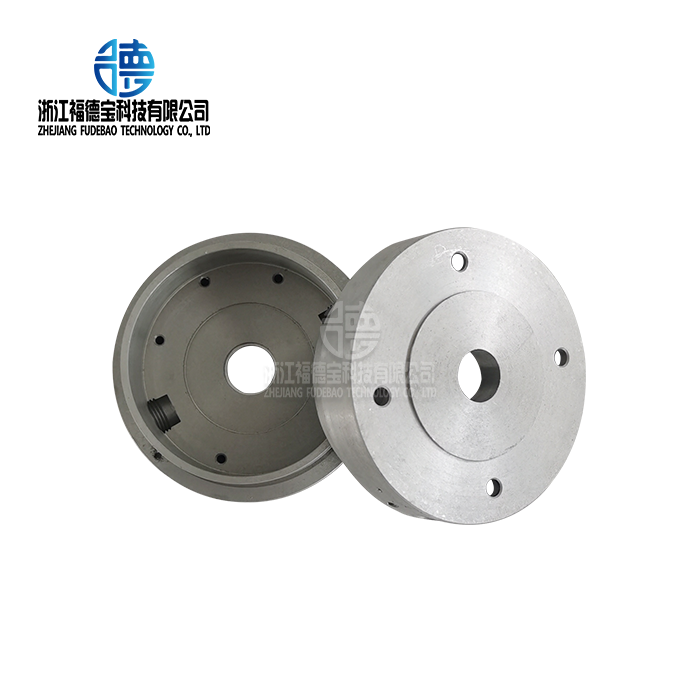

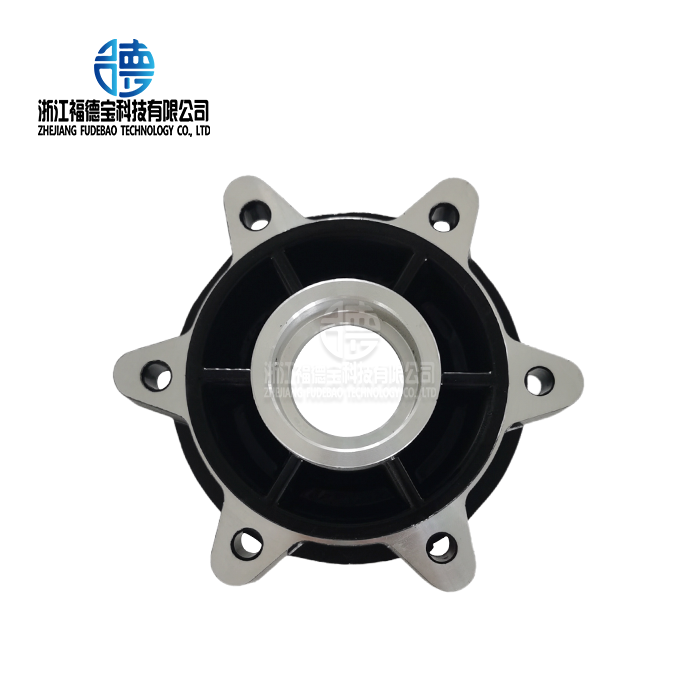

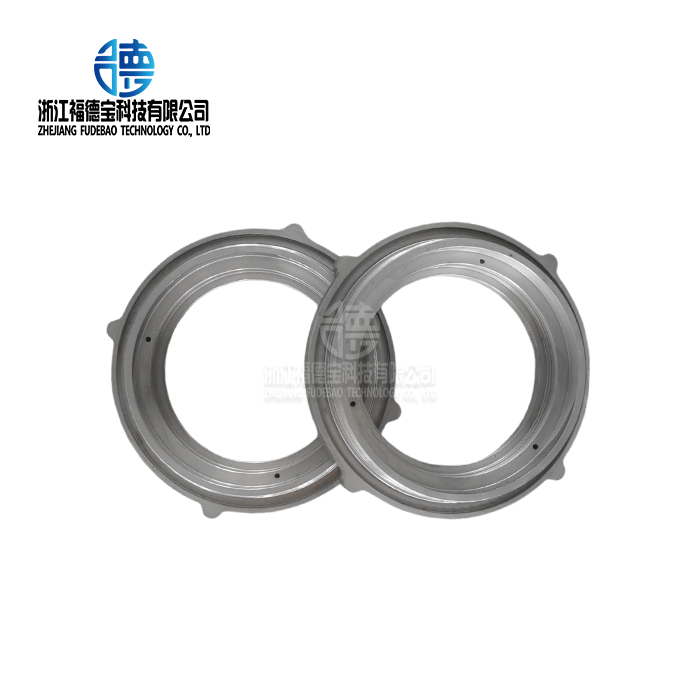

Expert CNC Machining Services | Fudebao Technology

At Fudebao Technology, we specialize in precision CNC machining of aluminum alloy, copper alloy, stainless steel, and other metals. As a leading CNC machining supplier and manufacturer, we serve global industries including automotive, industrial equipment, and aviation. Our state-of-the-art facility ensures high-precision parts with accuracy up to ±0.05mm. For expert CNC machining services, contact us at hank.shen@fdbcasting.com.

References

Smith, J. (2022). "Advanced Materials in CNC Machining: A Comprehensive Guide." Journal of Manufacturing Technology, 45(3), 234-248.

Johnson, R. et al. (2021). "Comparative Analysis of Aluminum Alloys for CNC Machining." International Journal of Materials Engineering, 12(2), 87-102.

Brown, L. (2023). "Sustainable Practices in CNC Machining: Materials and Methods." Green Manufacturing Quarterly, 18(1), 56-70.

Davis, M. (2022). "The Role of Composite Materials in Modern CNC Machining." Composites World, 7(4), 112-125.

Thompson, S. (2021). "Optimizing CNC Machining Processes for Various Materials." Journal of Precision Engineering, 33(2), 178-192.

Wilson, K. (2023). "Emerging Trends in CNC Machining Materials: A Industry Perspective." Advanced Manufacturing Technology, 29(3), 301-315.

_1756352400994.webp)