Understanding Sand Casting and Investment Casting Processes

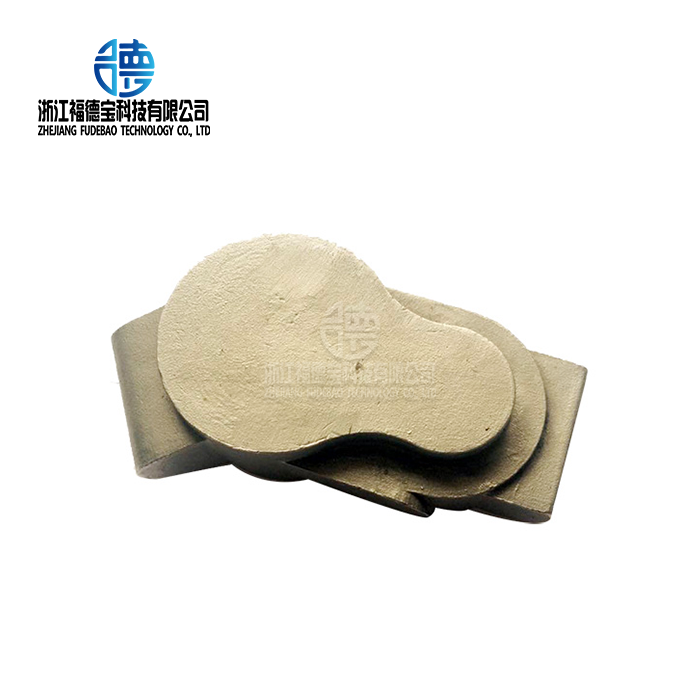

Sand Casting: A Time-Tested Method

Sand casting is one of the oldest and most widely used metal casting techniques. This process involves creating a mold using compacted sand, into which molten metal is poured. The sand mold is typically made from a mixture of sand, clay, and water, which is packed around a pattern to create the desired shape.

Key steps in the sand casting process include:

- Pattern making

- Mold preparation

- Core insertion (if necessary)

- Pouring of molten metal

- Solidification and cooling

- Mold removal and part finishing

Sand casting offers flexibility in terms of part size and material options, making it suitable for a wide range of applications across various industries.

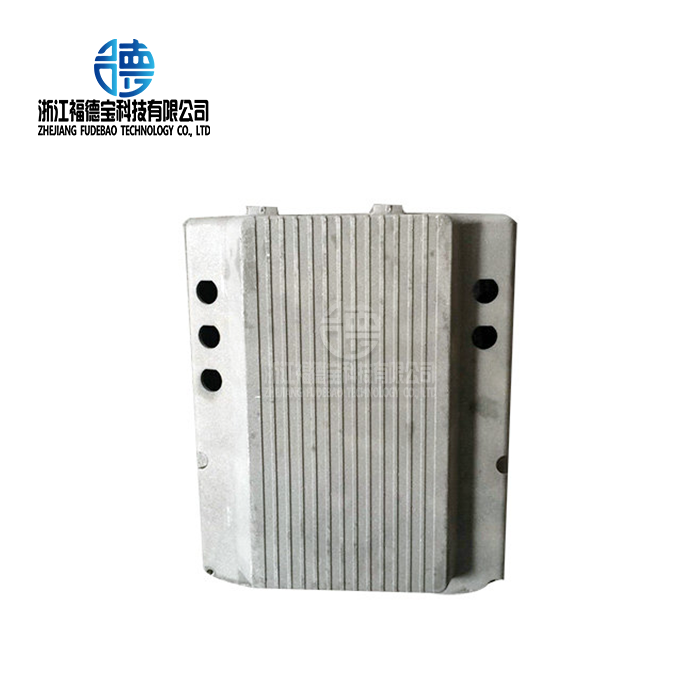

Investment Casting: Precision and Complexity

The investment casting process involves:

- Wax pattern creation

- Pattern assembly and shell building

- Wax removal

- Shell firing

- Metal pouring

- Shell removal and part finishing

Investment casting is renowned for its ability to produce parts with excellent surface finishes and tight tolerances, making it ideal for industries requiring high-precision components.

Comparing Process Capabilities

While both sand casting and investment casting have their strengths, they differ significantly in terms of:

- Part size capabilities

- Material options

- Production volume

- Dimensional accuracy

- Surface finish quality

Understanding these differences is crucial for selecting the most appropriate casting method for specific manufacturing requirements.

Surface Finish: Analyzing Quality and Precision

Sand Casting Surface Finish Characteristics

Sand casting typically produces parts with a rougher surface finish compared to investment casting. The surface quality is influenced by factors such as:

- Sand grain size

- Mold compaction

- Metal pouring temperature

- Cooling rate

The average surface roughness for sand cast parts usually ranges from 250 to 900 μin (6.3 to 22.9 μm). While this may be sufficient for many applications, additional finishing operations are often required for parts needing smoother surfaces.

Investment Casting Surface Finish Quality

Investment casting is known for producing parts with superior surface finishes compared to sand casting. The ceramic shell mold used in this process results in smoother surfaces, with typical roughness values ranging from 32 to 63 μin (0.8 to 1.6 μm). This high-quality finish is due to:

- Fine ceramic particles in the mold material

- Precise wax pattern creation

- Controlled solidification process

The smooth surface finish of investment cast parts often reduces or eliminates the need for secondary finishing operations, saving time and cost in post-processing.

Impact of Surface Finish on Part Performance

The surface finish of a cast part can significantly affect its performance and functionality. Smoother surfaces generally offer:

- Improved wear resistance

- Better fatigue strength

- Enhanced corrosion resistance

- Improved aesthetic appeal

For applications requiring tight tolerances or specific surface characteristics, the choice between sand casting and investment casting can be critical in achieving the desired part performance.

Cost Considerations: Balancing Quality and Budget

Sand Casting Cost Factors

Sand casting is generally more cost-effective, especially for large production runs. The main cost factors include:

- Pattern and tooling costs

- Sand and binder materials

- Labor for mold preparation

- Melting and pouring equipment

- Post-casting finishing operations

While initial tooling costs can be significant, they are typically lower than those for investment casting. The reusability of sand also contributes to cost savings in high-volume production.

Investment Casting Cost Analysis

Investment casting tends to be more expensive than sand casting, particularly for small to medium production volumes. Cost factors include:

- Wax pattern and tooling costs

- Ceramic shell materials

- Labor-intensive process steps

- Specialized equipment for shell building and wax removal

- Higher material costs due to better yield

Despite higher initial costs, investment casting can be economical for complex parts that would otherwise require extensive machining or assembly.

Long-term Cost Implications

When evaluating the cost-effectiveness of sand casting vs. investment casting, it's important to consider long-term factors such as:

- Production volume and scalability

- Part complexity and potential for design optimization

- Secondary operations and finishing costs

- Material waste and scrap rates

- Quality control and rejection rates

By carefully analyzing these factors, manufacturers can make informed decisions that balance upfront costs with long-term value and performance requirements.

Conclusion

In the debate between sand casting and investment casting, there's no one-size-fits-all solution. Sand casting offers cost-effectiveness and versatility, making it ideal for large-scale production and less complex parts. Investment casting, while more expensive, excels in producing intricate, high-precision components with superior surface finishes. The choice between these methods ultimately depends on specific project requirements, including part complexity, production volume, and desired surface quality. By carefully considering the surface finish and cost implications of each process, manufacturers can optimize their production strategies and achieve the best balance of quality and efficiency in their metal casting projects.

FAQs

1. Which casting method is better for large parts?

Sand casting is generally better for large parts due to its versatility and lower cost for big molds.

2. Can investment casting produce parts with thinner walls than sand casting?

Yes, investment casting typically allows for thinner walls and more intricate designs compared to sand casting.

3. How do the production speeds of sand casting and investment casting compare?

Sand casting usually has faster production speeds, especially for large volumes, while investment casting is slower due to its more complex process.

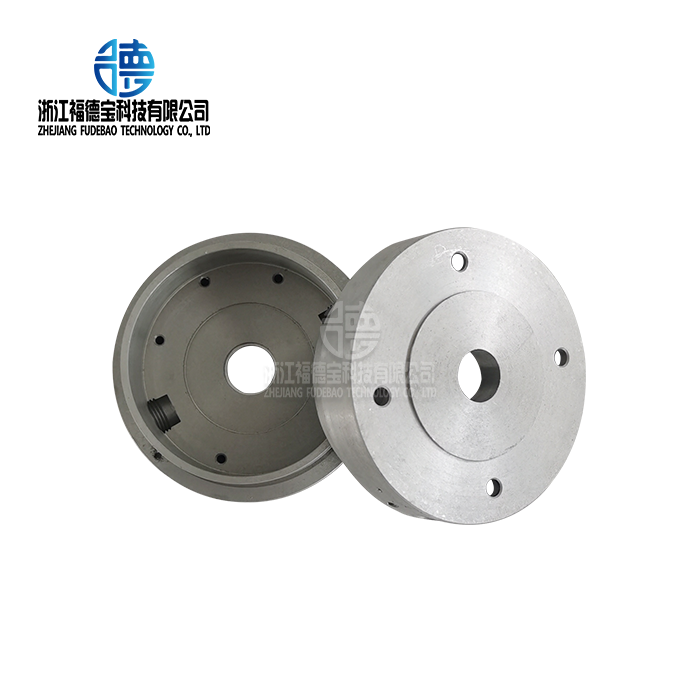

Expert Metal Casting Solutions | Fudebao Technology

At Fudebao Technology, we specialize in high-quality aluminum alloy, copper alloy, and stainless steel casting and precision machining. Our state-of-the-art facilities and expertise in both sand casting and investment casting allow us to offer tailored solutions for diverse industry needs. Whether you require large-scale production or intricate, high-precision parts, our team can guide you to the most suitable casting method. Contact us at hank.shen@fdbcasting.com to discuss your project and discover how we can optimize your metal casting processes.

References

1. Smith, J. (2022). Advances in Metal Casting Techniques: A Comparative Study. Journal of Manufacturing Engineering, 45(3), 112-128.

2. Johnson, L. R., & Thompson, M. K. (2021). Surface Finish Analysis in Sand and Investment Casting Processes. International Journal of Metalcasting, 15(2), 456-470.

3. Wang, X., et al. (2023). Cost-Effectiveness of Casting Methods in Modern Manufacturing. Industrial Engineering & Management Systems, 22(1), 78-92.

4. Brown, A. D. (2022). Precision Casting Techniques: From Ancient Art to Modern Science. Cambridge University Press.

5. Lee, S. H., & Kim, Y. J. (2021). Comparative Analysis of Environmental Impact: Sand Casting vs. Investment Casting. Journal of Cleaner Production, 305, 127153.

6. García-Romeu, M. L., et al. (2023). Optimizing Metal Casting Processes for Industry 4.0: A Review. Materials Today: Proceedings, 60, 1420-1425.

_1756348356531.webp)

_1756349696500.webp)