One of the most important recent changes in manufacturing is low pressure casting technology. It makes metal parts with great quality and speed. This improved casting method meets important needs in the industry by making it possible to make very exact parts with a lot fewer problems than older casting methods. This technology is very important for a lot of different areas, like cars, airplanes, industrial machines, and electrical equipment making. It helps them keep their production costs low while still meeting strict quality standards.

Understanding Low Pressure Casting and Its Core Advantages

The low pressure casting process is a controlled way of shaping metal with pressure that is very different from standard gravity casting methods. This advanced method uses very exact air pressure, usually between 0.1 and 1.0 bar, to fill molds from the bottom. This makes a steady flow of metal that doesn't have any bumps or changes in speed.

Process Mechanics and Material Benefits

The controlled filling process gets rid of the intense splashes and air trapping that are common in gravity casting methods. Metal that is still hot and liquid moves easily through a tube that is attached to the bottom of the mold and up into it. This makes sure that the metal fills up the entire space while avoiding gas bubbles and oxide inclusions. This systematic way of doing things leads to better mechanical qualities and surface finish in the castings.

Material Compatibility and Performance

Aluminum metals are great for this casting method because they flow well and harden in a way that works well with the process. The process can be used with different grades of aluminum, such as A356, A357, and ADC12. Each grade has its own benefits for different uses. Magnesium alloys also work great when there is low pressure. They are lightweight materials for uses where weight is important.

Top Industries Leveraging Low Pressure Casting Technology

Low pressure casting technology has been welcomed as an important manufacturing answer by a number of key businesses, each of which benefits in a unique way that fits with how they specifically operate.

Automotive and Transportation Sector

The automobile industry is the biggest user of low-pressure cast parts, which are used to make important parts for engines, housings for transmissions, parts for suspensions, and structural elements. Auto companies rely on this process to make metal wheels that are light but very strong and exactly the right size. The technology makes it possible to produce a lot of items with complicated shapes while keeping the quality high, which is important for car safety rules.

Aerospace and Defense Applications

Aerospace makers use this casting method to make parts of the structure, engine housings, and landing gear. These parts need to be very reliable and have exact measurements. The process meets strict aerospace standards, such as those spelled out in the AS9100 approval, and also provides the low-weight, high-strength features that are necessary for flight-critical uses. The tech's ability to make complex internal shapes while keeping the strength of the material intact is especially important to defense companies.

Industrial Machinery and Equipment Manufacturing

Pump housings, compressor parts, gearbox cases, and hydraulic system parts are all made by heavy equipment makers using low pressure casting. The technology provides the strength and steadiness needed for industrial uses while also making sure that the medium to large batch numbers common in machinery production are possible. Because these parts often have to work in very harsh conditions, the ability to make materials denser through controlled pressure filling is very useful.

Electrical and Energy Sector Components

Low pressure casting is used in the electrical business to make parts for motors, transformers, electrical casings, and ways to get rid of heat. The process's ability to make complicated cooling fans and electrical housings with great thermal conductivity really helps renewable energy uses. Pressure casting's exact physical control makes sure that the electrical gaps and heat management performance are right.

Comparing Low Pressure Casting to Other Casting Methods for Industry Applications

Understanding the benefits of pressure-controlled casting over other ways helps buying experts make good choices about how to make things.

Low Pressure vs. Gravity Casting Performance

Traditional gravity casting uses only gravity to fill the empty spaces in the mold. This can cause the metal to move in a rough way, which leads to mistakes in the final product. Low pressure ways get rid of these problems by filling in a controlled way, which leads to better casting density and lower porosity rates. It also takes a lot less time to make things. Systems that use pressure instead of gravity usually cut casting processes by 20% to 30%, which is a big improvement.

Comparison with High Pressure Die Casting

High-pressure die casting works best for making a lot of small parts, but low-pressure die casting is better for making medium-sized parts in medium-sized batches because it is more flexible. The managed pressure method works with bigger wall parts and complicated shapes on the inside that would be hard to do with high-pressure methods. The cost of tools is still a lot lower than that of die casting equipment, which makes the technology easier to reach for a wider range of output needs.

Evaluating Procurement Aspects and Selecting Reliable Low Pressure Casting Suppliers

Careful review of suppliers and smart buying plans are needed to make pressure casting options work.

Supplier Capability Assessment

Looking at a possible partner's tools, quality approval methods, and professional knowledge is important when making a decision. ISO 9001 is a method for managing quality that many top suppliers use, along with other standards that are special to their industries, like TS 16949 for cars or AS9100 for aircraft parts. The ability to produce, the time it takes to get something made, and the availability of extra processing services are also very important when choosing a provider.

Technology and Equipment Considerations

The filling pressure, temperature profiles, and cycle time are all precisely monitored by modern low pressure casting equipment's sophisticated process control systems. Suppliers who use newer machinery usually get better stability and lower failure rates than those who use older ones. Buyers can make sure that the quality they need matches the professional skills of the seller when they know what the tools can do.

Integrating Low Pressure Casting Solutions into Your Manufacturing Process

For integration to work, there needs to be a lot of planning that makes sure the way things are made can meet the output goals and quality standards.

Implementation Strategy and Quality Control

A detailed feasibility study that looks at part dimensions, material needs, production numbers, and quality standards is the first step to implementing pressure casting options. Statistical process control tracking, measurement checking routines, and material property verification tests are all quality control measures. These systems make sure that the output quality stays the same and find possible problems before they affect the production plan.

Process Optimization and Future Trends

Ongoing process improvement means adjusting pressure profiles, temperature control settings, and cycle time to get the best quality and efficiency. New technologies, like systems that measure pressure in real time and machines that do quality checks automatically, are making pressure-controlled casting ways even better. These new inventions let makers meet standards that are becoming more difficult to meet, all while keeping production costs low.

Conclusion

Low pressure casting technology keeps changing manufacturing in a number of areas by providing better quality, higher speed, and cheaper ways to make things. This technology has unique benefits like fewer mistakes, better material qualities, and the ability to make a wide range of products. These benefits are especially helpful to the automobile, aircraft, industrial gear, and electrical sectors. As the needs of manufacturing change toward more complicated shapes and strict quality standards, pressure-controlled casting methods offer the dependability and accuracy needed to do well in a competitive market. When buying workers and engineering teams know these perks, they can make smart choices that improve their manufacturing methods and product performance.

FAQs

What common problems happen in low pressure casting and how can they be avoided?

Common flaws are porosity, cold shuts, and inclusions. These can be greatly avoided by exact control of filling pressure, temperature, gate design, and mold quality. These problems during production can be spotted and avoided with the help of advanced process tracking tools.

How is low pressure casting cheaper than other ways when it comes to making things?

It is cheaper to use materials more efficiently, lower scrap rates, improve cycle times, and lower tooling costs compared to high-pressure options. The technology also reduces the need for extra cutting by providing better surface finish and measurement accuracy.

Which metals are best for low pressure casting in commercial settings?

Aluminum alloys like A356, A357, and ADC12 have great performance because they are easy to shape, strong, and resistant to rust. Magnesium alloys are also great for uses where weight is important, and some copper alloys are best for electrical applications that need high conductivity.

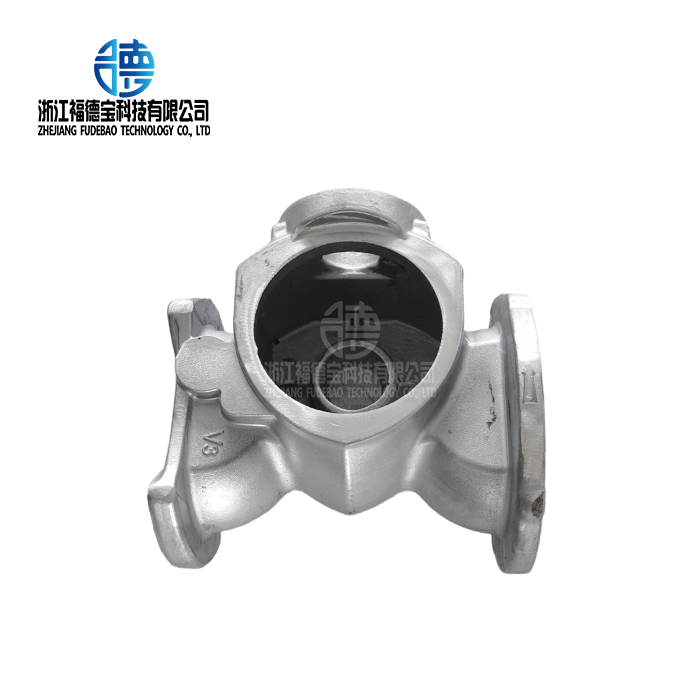

Partner with Fudebao Technology for Advanced Low Pressure Casting Solutions

Aluminum alloy, copper alloy, and stainless steel casting options for international markets are the focus of Zhejiang Fudebao Technology Co., Ltd., a leading low pressure casting producer. Our wide-ranging manufacturing skills cover the whole production process, from melting to finishing and surface treatment. We provide all-in-one solutions that take a blank piece of material and turn it into a finished part.

High-speed machining centers, CNC lathes, and sophisticated low pressure casting tools with precise tolerances of up to 0.05 mm are among the cutting-edge equipment in our building. This level of accuracy, which is only possible in ideal conditions, meets the high standards of the car industry, medical equipment housings, and aircraft parts. We serve a range of businesses, such as automobile, industrial equipment, tool production, and flight, and we are always committed to quality and dependability.

We are a trusted low pressure casting source who offers a full range of OEM services and custom manufacturing solutions designed to meet your exact needs. We can help you get the best results for your important projects because our knowledge covers everything from the first planning meeting to the delivery of the final product. Get in touch with our expert team to learn how our improved casting methods can help you make your products faster and with better quality. To talk about your project's needs and get a tailored solution offer, email us at hank.shen@fdbcasting.com.

References

Campbell, J. (2015). Complete Casting Handbook: Metal Casting Processes, Metallurgy, Techniques and Design. Butterworth-Heinemann.

Dispinar, D., & Campbell, J. (2011). Critical assessment of reduced pressure test. Part 1: Porosity phenomena. International Journal of Cast Metals Research, 17(5), 280-286.

Tiryakioğlu, M. (2020). On the relationship between structural quality index and fatigue life of A356-T6 cast aluminum alloys. Materials Science and Engineering: A, 772, 138776.

Czerwinski, F. (2021). Current trends in automotive lightweighting strategies and materials. Materials, 14(21), 6631.

Monroe, R. (2016). Porosity in Castings. AFS Transactions, 124, 493-512.

Stadler, F., Antrekowitsch, H., Fragner, W., Kaufmann, H., & Uggowitzer, P. J. (2012). Effect of main alloying elements on strength of Al–Si foundry alloys at elevated temperatures. International Journal of Cast Metals Research, 25(4), 215-224.

_1756346668222.webp)

_1756350046757.webp)

_1756350092126.webp)