Typical Uses of Low Pressure Casting in Industry

2026-01-15

Low pressure casting is an advanced production process that produces outstanding outcomes in a variety of industrial industries. This regulated procedure fills molds with molten metal under low pressure, producing parts with excellent surface quality and precise dimensions. Low pressure casting, in contrast to conventional gravity casting techniques, guarantees uniform material flow and minimizes porosity, making it perfect for creating intricate geometries and thin-walled structures that satisfy exacting quality requirements.

Understanding the Low Pressure Casting Process

A simple yet efficient idea underpins the low pressure casting process. Under regulated pressure, usually between 0.1 and 1.0 bar, molten metal enters the mold cavity by a riser tube from a sealed furnace. By removing air entrapment and turbulence, this gentle filling method produces castings with superior mechanical qualities and few flaws.

Advanced automation systems that accurately regulate cooling cycles and pressure settings are a feature of modern low pressure casting processes. Throughout the casting cycle, the equipment's advanced monitoring features track pressure changes and temperature gradients. Repeatability and consistency in quality across manufacturing runs are guaranteed by this degree of control.

Although copper and other non-ferrous metals also benefit from this method, it works especially well with aluminum alloys. Castings with clean internal structures and superior surface finishes are produced by the controlled environment, which inhibits oxidation and contamination.

Automotive Industry Applications

One of the biggest markets for low pressure casting applications is the automobile industry. In order to increase performance and fuel economy, automakers are calling for lightweight parts that preserve structural integrity while lowering the total weight of the vehicle.

Perhaps the most obvious use of this technique is in the manufacture of wheels. Wheels with intricate spoke designs and thin walls are produced via low pressure die casting, which is not achievable with conventional techniques. The procedure removes the porosity problems typical of gravity-cast wheels and guarantees even material distribution. This method is used by major automakers to make millions of wheels for trucks, motorbikes, and passenger automobiles every year.

The benefits of low pressure casting are substantial for engine components. Excellent surface finish quality and exact dimensional tolerances are necessary for engine blocks, intake manifolds, and cylinder heads. Even in complicated geometries with thin sections and intricate cooling passageways, the regulated filling process guarantees full cavity filling and inhibits the development of cold shuts.

Control arms, knuckles, and housing assemblies are examples of suspension parts that depend on the higher mechanical qualities made possible by low pressure casting. Gas porosity and shrinkage flaws that can jeopardize component strength and durability under dynamic loading conditions are eliminated by the method.

Industrial Machinery Components

For pumps, compressors, and gearbox housings, makers of heavy equipment use low pressure casting to create sturdy parts. Parts that can tolerate high pressures, temperature changes, and continuous operating cycles are required for these applications.

The process benefits in industrial applications are best shown by pump housings. The process creates castings with smooth interior surfaces that maximize fluid flow properties without compromising pressure integrity. Without the need for significant secondary machining procedures, intricate internal channels and mounting elements blend flawlessly.

The leak-proof properties of low pressure casting are advantageous to hydraulic components. To stop fluid leakage at high pressure, valve bodies, manifolds, and actuator housings must have zero porosity. Internal voids are almost eliminated and pressure containment is ensured by the process's controlled environment and progressive solidification feature.

Another important use area is heat exchanger components. Low pressure casting is perfect for making heat transfer components for HVAC systems and industrial cooling systems because it can produce thin-walled sections with superior thermal conductivity.

Electrical and Energy Sector Uses

Low pressure casting is used by the electrical sector for parts that need to have superior heat management and electrical conductivity. The excellent material qualities this technology produces are advantageous for renewable energy components, power transmission equipment, and motor housings.

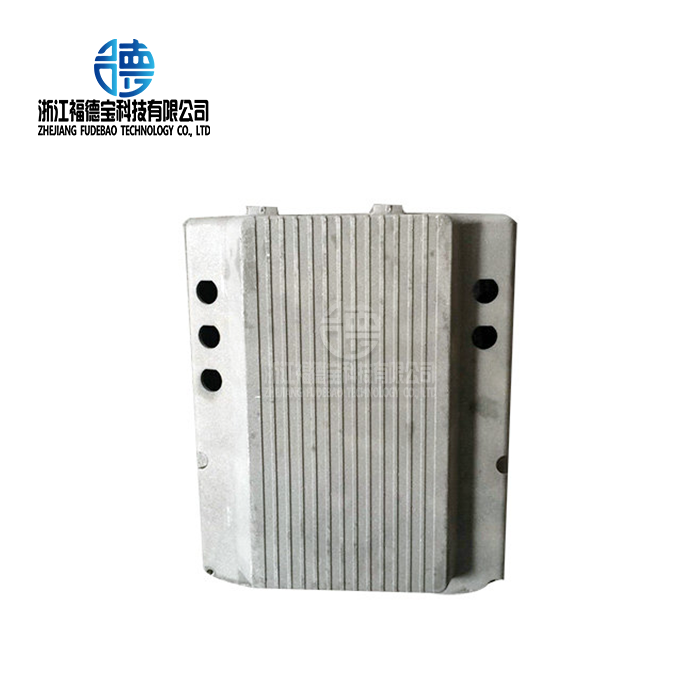

The process's adaptability in integrating functional needs is shown by electrical motor housings. These parts must have sufficient electromagnetic shielding qualities, heat dissipation capacity, and internal component mounting. Low pressure casting preserves dimensional stability under temperature changes while producing integrated cooling fins and mounting bosses.

Transformer parts make use of the superior dimensional precision and surface polish made possible by carefully managed pressure filling. In high-power applications, the method creates housings with integrated cooling tunnels and precise mounting features that maximize thermal management.

For structural parts that must endure exposure to the weather while maintaining exact alignment tolerances, low pressure casting is used more and more in solar panel mounting systems and wind turbine components. These castings' exceptional mechanical qualities and resistance to corrosion guarantee long-term operation in harsh outdoor settings.

Aerospace and Defense Applications

Because aerospace manufacturers have the strictest quality requirements, low pressure casting is the perfect option for vital flying components. The procedure accomplishes weight reduction objectives while providing the dependability and traceability needed for aviation applications.

Wing brackets, landing gear components, and engine mounts are examples of structural elements of aircraft that need remarkable strength-to-weight ratios. These performance goals are accomplished by low pressure casting aluminum alloys, which also allow for intricate shapes that maximize load distribution and reduce stress concentrations.

The low outgassing properties and dimensional stability of correctly cast aluminum alloys are advantageous for satellite components. Contamination that can impair component performance in space conditions is avoided by the controlled atmosphere used during casting.

Housings for communication equipment, pieces for weapon systems, and armor vehicle components are examples of defense uses. Consistent material qualities and dependable performance in harsh environments are required for these applications.

Marine and Offshore Applications

For parts exposed to corrosive saltwater conditions, the maritime sector uses low pressure casting. Materials with superior mechanical endurance and corrosion resistance are needed for deck hardware, engine parts, and propellers.

The capacity of the method to produce intricate hydrodynamic forms with accurate blade profiles is shown via propeller manufacture. By removing porosity that might cause cavitation damage, the higher surface polish lowers drag.

The corrosion resistance that may be achieved by appropriate alloy selection and regulated low pressure casting conditions is advantageous for offshore platform components including pumps, valves, and structural parts. Despite constant exposure to hostile maritime conditions, these components must remain intact.

Medical Equipment Applications

Low pressure cast components are being increasingly specified by medical device makers for equipment that needs fine tolerances and biocompatible materials. The clean, pore-free structures that are created by this method are advantageous for imaging equipment, surgical tools, and diagnostic device housings.

Non-magnetic materials with outstanding dimensional stability are needed for MRI and CT scanner components. These specifications are satisfied by low pressure casting aluminum alloys, which also provide the structural strength required for accurate mechanical positioning systems.

The surfaces of surgical equipment housings must be bacterially resistant, smooth, and simple to clean. Controlled pressure filling produces a higher surface quality that reduces surface roughness and removes possible contamination locations.

Process Advantages and Quality Benefits

Compared to traditional gravity casting techniques, low pressure casting offers many benefits. Cleaner interior structures with better mechanical qualities are produced by the regulated filling process, which also lowers oxide inclusion development and removes turbulence.

Reduced shrinkage porosity and a predictable solidification pattern lead to increases in dimensional accuracy. Components reduce lead times and production costs by achieving tolerances within ±0.05mm without requiring significant secondary machining.

Surface finish quality is close to die casting standards and better than sand casting. By reducing or eliminating finishing procedures, this enhancement streamlines manufacturing processes and increases cost effectiveness.

Because the pressured filling mechanism guarantees full mold cavity use, material yield is much higher than with gravity casting. Production economics are directly impacted by lower scrap rates and better material use.

Quality Control and Inspection Methods

Comprehensive quality control systems that keep an eye on every step of the manufacturing process are used in modern low pressure casting plants. Consistent casting conditions are guaranteed during production runs thanks to real-time temperature and pressure monitoring.

Internal soundness and dimensional conformity are confirmed by non-destructive testing techniques such as pressure testing, ultrasonic testing, and X-ray inspection. These inspection procedures satisfy aerospace certification criteria as well as automotive PPAP regulations.

Systems for statistical process control monitor important casting parameters and spot patterns that might point to process drift. By being proactive, quality problems are avoided before they have an impact on production delivery.

Moving Forward with Low Pressure Casting

Low pressure casting is still being used in a variety of industrial areas because to its adaptability and quality benefits. This technology offers solutions that satisfy both technical specifications and production costs as manufacturers deal with the growing need for lightweight, high-performance components.

Engineering teams may assess if low pressure casting meets their unique component needs by having a thorough understanding of these common applications. When applications call for intricate geometries that defy standard casting techniques, exceptional surface polish, or dimensional precision, the procedure is very valuable.

The right alloy selection, optimal mold design, and process parameter selection are essential for low pressure casting success. Access to the technical know-how required to optimize the advantages of this cutting-edge casting method is ensured by collaborating with seasoned manufacturers.

FAQ

Which materials are most effective for low pressure casting?

The most popular materials for low pressure casting applications are aluminum alloys. A356, A357, and AlSi7Mg are popular alloys because of their superior mechanical and castability qualities. This method also works well with certain magnesium alloys and copper alloys.

What is the quality difference between gravity casting and low pressure casting?

Higher quality components with less porosity, greater surface polish, and increased dimensional accuracy are usually produced using low pressure casting. Superior mechanical qualities are achieved while numerous frequent faults in gravity casting are eliminated by the regulated filling procedure.

Which pressure parameters are often used in low pressure casting?

Depending on the shape of the component and the properties of the alloy, operating pressures usually fall between 0.1 and 1.0 bar. Pressure is applied according to preprogrammed curves that maximize mold filling while avoiding air entrapment and turbulence.

Is it possible to create components with thin walls using low pressure casting?

With wall thicknesses as low as 2-3 mm, the technique is excellent at creating thin-walled components. Even in areas that would be difficult to cast using gravity techniques, the regulated pressure guarantees full mold filling.

What are the usual low pressure casting cycle times?

For most applications, cycle times fall between two and ten minutes, however they might vary depending on the complexity and size of the component. With accurate process control, automated systems can maximize cycle times while upholding quality requirements.

What are the differences in mold design for low pressure casting?

The bottom-filling property of low pressure casting must be taken into account while designing molds. Venting systems control air displacement during filling, whereas gating systems attach to the cavity's lowest point. The design of the cooling system maximizes directed solidification.

Partner with Fudebao Technology for Expert Low Pressure Casting Solutions

Fudebao Technology is prepared to serve as your go-to low pressure casting manufacturer by fusing decades of industry experience with cutting-edge equipment capabilities. Modern low pressure casting equipment and precise CNC machining centers are housed in our facilities, providing comprehensive solutions from raw materials to completed components. To discuss your unique needs and learn how our extensive production capabilities can maximize your product development timeframe and quality targets, get in touch with hank.shen@fdbcasting.com.

References

Campbell, John. "Complete Casting Handbook: Metal Casting Processes, Metallurgy, Techniques and Design." Butterworth-Heinemann, 2015.

Bonollo, Franco, et al. "Gravity and Low-Pressure Die Casting of Aluminium Alloys: A Technical and Economical Benchmark." La Metallurgia Italiana, 2018.

American Foundry Society. "Low Pressure Permanent Mold Casting Guidelines and Best Practices." AFS Technical Publication, 2019.

Kaufman, J. Gilbert. "Introduction to Aluminum Alloys and Tempers." ASM International, 2017.

European Aluminium Association. "Aluminium Automotive Manual - Casting Applications." EAA Technical Guidelines, 2020.

Zhang, Weiming, and Liu Hongwei. "Advanced Manufacturing Technologies for Automotive Light-weighting Applications." Materials Science Forum, 2021.

_1756346371362.webp)

_1756345858191.webp)

_1756352625880.webp)

_1756361423150.webp)