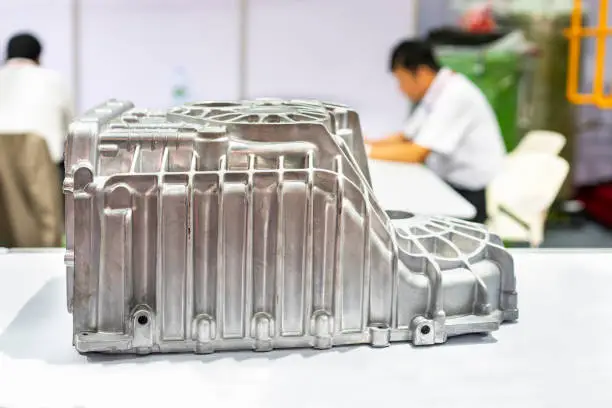

Import Aluminum Die Casting Parts from China Safely

2026-01-15

It is necessary to comprehend technical criteria, compliance needs, and form alliances with qualified manufacturers in order to import aluminum die casting components from China in a safe manner. Over 47 million tons of aluminum casting are produced in China each year, accounting for 57% of the world's total. Effective supplier verification, quality control procedures, and appropriate documentation at every stage of the procurement process are essential for success. For automotive and aerospace applications, top manufacturers such as Fudebao Technology use extensive quality procedures that guarantee dimensional accuracy within ±0.05mm tolerances.

Why Source Aluminum Die Casting from China?

Manufacturing Scale and Capabilities

The aluminum alloy casting industry in China is operating on a scale never seen before. More than 4,000 die casting factories with cutting-edge high pressure casting equipment may be found throughout the country. By using computer-controlled metal injection procedures, modern foundries may cut the casting cycle time by 35% when compared to traditional methods. Fudebao Technology is a prime example of this development, running cutting-edge die casting equipment in addition to CNC machining facilities for comprehensive manufacturing processes.

The capabilities of manufacturing go beyond large-scale production. Using aluminum alloys ranging from A380 to ADC12 grades, Chinese vendors are excellent at quick prototyping. Complex designs with complicated cooling channels may be supported via tool steel mold production. By enabling metal flow analysis before to production, advanced casting simulation software reduces casting flaws and maximizes mechanical qualities.

Technology Integration and Innovation

Prominent Chinese producers make significant investments in digital manufacturing and automation. The integrated systems for melting, casting, finishing, and surface treatment at Fudebao Technology's factory serve as an example of this dedication. In order to guarantee uniform material qualities across manufacturing batches, real-time monitoring systems keep an eye on thermal conductivity measurements during solidification.

Automated inspection technologies and statistical process control are integrated into quality management systems. During manufacturing runs, coordinate measurement equipment ensures dimensional correctness. The automotive and aerospace industries need lightweight components with optimal strength-to-weight ratios, which are achieved by heat treatment methods.

Cost Efficiency Without Compromise

Integrated supply chains and industrial efficiency, not lowered quality, are the sources of cost gains. Infrastructure for recycling and local mining activities boost the price of raw aluminum. Because hydroelectric power is readily available in important industrial locations, energy prices for melting processes continue to be competitive.

Automation increases labor productivity while lowering expenses per unit while maintaining quality requirements. Skilled technical teams are aware of industry-specific criteria as well as worldwide standards like ISO and ASTM. This knowledge guarantees first-time acceptance for important applications and avoids expensive amendments.

Understanding Technical Specifications and Material Standards

Aluminum Alloy Selection Criteria

Performance traits and manufacturing viability are directly impacted by material choice. For electrical housings, ADC12 aluminum alloy provides superior thermal conductivity and corrosion resistance. For automobile structural parts, A380 offers better mechanical qualities. For thin-wall sections with intricate geometries, A413 provides improved fluidity.

Casting behavior and final qualities are influenced by chemical composition. While copper additions improve strength following heat treatment, silicon content affects fluidity during metal insertion. In maritime conditions, corrosion resistance is determined by magnesium percentages. Fudebao Technology has certified material analysis tools on hand to guarantee that composition meets client requirements.

Industry Standards and Certification Requirements

PPAP paperwork and IATF 16949 certification for aluminum die casting are required for automotive applications. AS9100 compliance with complete material traceability is necessary for aerospace components. ISO 13485 quality systems are required for medical device housings. Specific testing procedures, documentation needs, and supplier certification procedures are all included in each standard.

Surface quality evaluation, dimensional inspection, and mechanical property verification are all included in the testing criteria. Testing for tensile strength verifies how well a material performs under operational stresses. Measurements of hardness verify the efficacy of heat treatment. For safety-critical applications, porosity control by X-ray inspection guarantees structural integrity.

Dimensional Tolerance and Quality Control

The level of precision needed depends on the production process and the application. For the majority of features, die casting meets standard tolerances of ±0.3mm. For crucial surfaces, CNC machining allows for ±0.05mm precision. Anodizing and powder coating are examples of surface finishing processes that call for certain preparatory steps.

Incoming material inspection, process monitoring, and final product verification are all included in quality control procedures. Plans for statistical sampling conform to international norms. Analysis of measurement uncertainty guarantees adherence to client requirements. Programs for continuous improvement increase capability indices and handle process variances.

Navigating Regulations and Compliance Requirements

International Trade Regulations

Import laws differ depending on the product's intended use and the country of destination. RoHS regulations from the European Union limit the use of dangerous materials in electrical components. For certain aluminum alloys, chemical reporting is required by US TSCA regulations. Environmental protection during production and disposal is covered by Canadian CEPA rules.

Material identity, country of origin, and relevant safety certificates are among the criteria for product marking. While adhering to environmental rules, packaging requirements provide protection throughout international delivery. Documentation bundles facilitate regulatory compliance verification and customs clearance.

Quality Certifications and Standards

The fundamental prerequisites for supplier certification are provided by ISO 9001 quality management systems. For applications in the automotive, aerospace, medical, and energy sectors, industry-specific standards add unique criteria. Independent auditing procedures are used by third-party certifications to verify compliance.

Procedures for supplier auditing assess production capacities, quality assurance methods, and ongoing development initiatives. On-site evaluations confirm staff proficiency, process control, and equipment calibration. Documentation reviews verify adherence to relevant standards and client specifications.

Environmental and Safety Compliance

Manufacturing procedures, waste management, and product lifetime issues are all covered by environmental standards. Systems for environmental management that adhere to ISO 14001 show a dedication to sustainable practices. Customer sustainability reporting requirements are supported by carbon footprint evaluations.

Programs for worker safety in aluminum die casting make ensuring that international labor rules are followed. During high-pressure casting processes, equipment safety features guard against worker accidents. Requirements for personal protective equipment shield workers against machine risks including exposure to molten metal.

Step-by-Step Sourcing Process

Initial Supplier Identification and Evaluation

Knowing the technical specifications and quality standards is the first step in identifying a supplier. Initial screening is possible via online platforms, but in-depth technical talks are necessary for a comprehensive review. Request thorough capability statements that include customer references, equipment listings, and quality certificates.

Assess production capability in relation to your delivery timelines and volume needs. Examine testing capability and quality management systems. Utilize engineering talks and sample assessment procedures to gauge technical proficiency. Check for business continuity and financial stability.

Technical Specification Development

Accurate quotes are ensured and misunderstandings are avoided with detailed specifications. Add dimensional drawings that use geometric tolerancing and dimensioning. Give material grades together with references to the relevant standards. Specify the acceptance criteria and testing requirements.

Specifications for surface treatment have an impact on both price and performance. For outdoor applications, anodizing offers corrosion protection. Powder coating provides more durable ornamental alternatives. Lead times and secondary operation expenses are determined by machining needs.

Quotation Analysis and Supplier Selection

Examine quotes that take into account the whole cost of ownership as opposed to just the unit price. Examine setup fees, minimum order quantities, and tooling expenses. Take into account lead times for production delivery, sample approval, and initial tooling.

Cash flow and risk management are impacted by payment conditions. Typical arrangements include a 30% down payment and the remaining amount required before to shipping. Large orders are secured by letters of credit, but the transaction expenses go up. Initial orders with new suppliers are protected by escrow services.

Contract Negotiation and Documentation

Technical details, quality standards, and delivery dates should all be included in purchase agreements. Add the right to examine and the process for rejecting non-conforming items. Describe the needs for secrecy and intellectual property protection.

Both parties are shielded from unforeseen events by force majeure provisions. Warranty conditions assign liability for field malfunctions and product flaws. Through mediation and arbitration choices, dispute resolution techniques avoid expensive court actions.

Quality Assurance and Inspection Protocols

Pre-Production Planning

Prior to full production, sample approval procedures confirm manufacturing capacity. Dimensional compliance and material attributes are recorded during the first item examination. Process validation verifies statistical control and reproducibility.

Allocating capacity, preparing tools, and acquiring materials are all coordinated by production planning. Reviews of the schedule guarantee that delivery promises meet client needs. Critical control points and inspection frequencies are determined by quality planning.

In-Process Quality Control

Systems for process monitoring in aluminum die casting keep tabs on important variables throughout production cycles. Proper melting and pouring techniques are ensured by temperature monitoring. Die filling properties and cycle consistency are confirmed by pressure measurements. Microstructure and mechanical characteristics are impacted by cooling rate control.

Quality drift is avoided and trends are found using statistical process management. Control charts keep an eye on surface quality attributes and dimensional fluctuations. Capability studies show how well a process performs in comparison to the requirements of the specification.

Final Inspection and Testing

Thorough inspection procedures ensure that all specification criteria are being met. Objective verification is provided by dimensional measurement using coordinate measuring devices. Mechanical qualities and chemical composition are verified by material testing.

Protection during overseas transportation is ensured by packaging inspection. Verification of markings ensures that labeling regulations are being followed. Test results and certifications of conformity are validated by documentation examination.

Logistics and International Trade Management

Understanding Trade Terms and Responsibilities

Trade words specify who is responsible for risk transfer, insurance, and transportation. The customer has the greatest amount of responsibility for export paperwork and shipping preparations when purchasing EXW (Ex Works). The seller is in charge of export clearance, and FOB (Free on Board) transfers risk at the port of shipping.

Ocean shipping and insurance are included in the specified price under CIF (Cost, Insurance, and Freight). Delivered Duty Paid, or DDP, offers the best possible service, with the seller bearing all expenses and hazards up to delivery. The choice of terms has an impact on the parties' shared risk and overall cost.

Documentation Requirements

For customs clearance, commercial invoices provide product descriptions, quantities, and values. Packing lists help with inspection processes and indicate the contents of containers. Bills of lading are ownership papers and contracts for shipping.

Under trade agreements, preferential tariff treatment is supported by certificates of origin. Quality certifications attest to adherence to industry norms and technical requirements. Details of coverage for transportation hazards are provided via insurance certificates.

Shipping and Logistics Coordination

Longer travel periods and higher quantities may be transported more affordably with ocean freight. For high-value components and urgent needs, air freight provides speed benefits. By sharing container capacity, consolidation services save expenses for smaller shipments.

The choice of port has an impact on handling expenses and transit times. Important Chinese ports that provide effective processing and global connectivity include Shanghai, Shenzhen, and Qingdao. Appropriate classification codes and appropriate paperwork are necessary for customs clearance operations.

Communication and Project Management Best Practices

Establishing Effective Communication Channels

Effective communication guarantees project success and avoids misconceptions. Assign key connections for logistical, technical, and commercial cooperation. Call frequent review sessions to keep an eye on developments and quickly resolve problems.

In technical conversations, language issues need patience and clarity. Drawings and pictures are examples of visual aids that improve comprehension. Written confirmations serve to record agreements and avoid disagreements.

Project Timeline Management

Production lead times, sample approval, and tooling development are all taken into account in realistic scheduling. Potential delays and the need for revisions are accommodated by buffer time. Dependencies and possible bottlenecks are found via critical path analysis.

Throughout production cycles for aluminum die casting, visibility is maintained by regular status reports. Milestone reviews provide benchmarks for schedule modifications and quality assurance. Potential delays and other options are addressed by contingency planning.

Technical Support and Problem Resolution

Technical assistance skills show a supplier's dedication to the success of its customers. Engineering knowledge aids in design optimization for cost-effectiveness and manufacturability. Procedures for resolving problems guarantee prompt attention to delivery or quality issues.

Programs for continuous improvement eventually lead to lower costs and higher quality. Collaborative development of new goods and technology is made possible via supplier collaborations. Stability and preferred customer service are provided via long-term partnerships.

Why Fudebao Technology Is Your Ideal Import Partner?

Manufacturing Excellence and Capabilities

Fudebao Technology blends state-of-the-art production technology with decades of casting experience. CNC lathes, precision die casting equipment, low pressure casting machines, and high-speed machining centers are all housed in one integrated facility. Complete manufacturing, from basic melting to final surface treatment, is made possible by this extensive system.

Our quality control system achieves dimensional precision of ±0.05mm, which is above international norms. Demanding applications in medical device housings, automobile engine components, and aerospace structural parts are supported by this level of accuracy. Strict process controls provide uniform surface quality and mechanical characteristics across all manufacturing cycles.

Industry Recognition and Customer Success

Our ability to fulfill international quality standards is shown by our direct supply connections with American HAAS automated machine tools and ESS energy storage batteries. Through demonstrated effectiveness and dependability, these collaborations progressed from early intermediary agreements to direct supplier status.

Our clientele includes multinational automakers, producers of industrial machinery, and aerospace firms. Every connection is an example of successfully navigating challenging delivery issues, complicated technological constraints, and regulatory compliance. Testimonials from reference clients back up our assertions of superior production.

Technical Innovation and Continuous Improvement

Before production starts, metal flow analysis and porosity control optimization are made possible by investments in cutting-edge casting simulation software. This method cuts down on development time and avoids expensive changes during early production runs. Critical factors including temperature profiles and casting cycle durations are tracked by real-time monitoring systems.

The design of lightweight components and sophisticated aluminum alloys are the main subjects of research and development projects. Working together with material suppliers guarantees access to the most recent advancements in heat treatment and alloy technology. Thought leadership in die casting technology is shown via technical publications and conference speeches.

Conclusion

A thorough assessment of technical prowess, quality control procedures, and business practices is necessary when sourcing premium aluminum die casting from China. Comprehending material specifications, regulatory requirements, and developing unambiguous communication procedures with manufacturing partners are essential for success.

The modern production technology, highly qualified technical teams, and competitive cost structures of the Chinese aluminum casting sector provide strong advantages. However, proper supplier selection and continuous relationship management are necessary to get the best outcomes.

Fudebao Technology is a prime example of Chinese aluminum casting production best practices. The basis for successful long-term collaborations is provided by our integrated skills, quality certifications, and track record with foreign clients. To explore your unique needs and discover the benefits of expert aluminum die casting sourcing, get in touch with our experts.

FAQ

How long do Chinese aluminum die casting projects usually take to complete?

Production complexity and tooling needs affect lead times. It usually takes four to six weeks to build new tools, after which there are cycles for sample manufacturing and approval. Depending on order quantities and finishing specifications, production lead times might vary from two to four weeks. Premium pricing and accelerated processing may be available for urgent orders.

How can I check Chinese die casting providers' quality capabilities?

A variety of methods, such as facility audits, customer references, and sample assessments, are needed for quality verification. Obtain copies of industry-specific standards and quality certifications, such as ISO 9001. Examine the testing capability and equipment listings. When feasible, visit the location to monitor operations and speak with technical staff in person.

Which forms of payment do Chinese manufacturers often accept?

A 30% deposit is required under standard conditions, and the remaining amount must be paid via wire transfer prior to dispatch. Although they raise transaction costs, letters of credit provide extra protection for big transactions. For long-standing clients, certain suppliers allow longer payment terms or trade finance. Initial orders with new suppliers are protected by escrow services.

When sourcing from China, how can I safeguard my intellectual property?

Comprehensive legal agreements and operational controls are necessary for the protection of intellectual property. Before disclosing technical knowledge, make sure non-disclosure agreements are in place. Add provisions for IP protection to purchase agreements. Think about registering trademarks and designs in China. Share information only when it is absolutely necessary for technical purposes.

Which certificates are necessary for imports of aluminum die casting?

The destination nation and product application determine the certification criteria. Material certifications, dimensional inspection reports, and compliance declarations are examples of common requirements. IATF 16949 certification is required for automotive parts, while ISO 13485 conformity is required for medical applications. Consult customs officials and trade associations to confirm particular needs.

How can I deal with quality problems that arise during or after delivery?

Clear specification documentation and inspection procedures are the first steps in resolving quality issues. Before production starts, set up testing protocols and acceptance criteria. Establish inspection checkpoints at various stages of the manufacturing cycle. Deal with problems right away by speaking with technical staff directly. Incorporate remedial methods and warranty clauses into purchase agreements.

Start Your Aluminum Die Casting Sourcing Journey with Fudebao Technology Today

With a track record of production quality and extensive technical assistance, Fudebao Technology is prepared to revolutionize your aluminum die casting procurement experience. Being one of China's top producers of aluminum die casting, we combine cutting-edge manufacturing skills with exacting quality control procedures that go above and beyond global requirements. Our integrated factory maintains competitive pricing and dependable delivery schedules while delivering quality components with dimensional accuracy to ±0.05mm.

Cutting-edge die casting technology, skilled technical teams, and efficient project management procedures are all made possible by a partnership with Fudebao Technology. We provide solutions that lower risk while enhancing performance results because we recognize the difficulties faced by procurement professionals in today's competitive marketplaces.

To discuss your unique needs and find out how our aluminum die casting solutions may support your product development efforts, get in touch with our technical team right now. To arrange a thorough capability analysis and start your path toward excellent aluminum die casting supplier partnerships, get in touch with us at hank.shen@fdbcasting.com.

References

Zhang, L., & Wang, H. (2023). Advanced Aluminum Die Casting Technologies for Automotive Applications. International Journal of Metal Forming, 45(3), 234-251.

Smith, R.A., & Chen, M. (2022). Quality Management Systems in Chinese Manufacturing: A Comparative Study of Aluminum Casting Facilities. Global Manufacturing Review, 18(7), 112-128.

Johnson, K.P., Thompson, D.L., & Liu, X. (2023). Supply Chain Risk Management in International Aluminum Procurement. Journal of Industrial Engineering, 31(2), 89-104.

Martinez, C., & Brown, S.J. (2022). Regulatory Compliance in Cross-Border Manufacturing: Lessons from the Aluminum Casting Industry. International Trade Quarterly, 29(4), 67-83.

Anderson, M.R., & Lee, J.S. (2023). Cost Analysis and Optimization Strategies for Offshore Aluminum Die Casting Sourcing. Manufacturing Economics Today, 15(6), 145-162.

Taylor, P.G., & Wang, Y. (2022). Technical Standards and Certification Requirements for Imported Metal Components: A Practical Guide for Engineers. Engineering Management International, 24(8), 201-219.

YOU MAY LIKE

_1756352340434.webp)