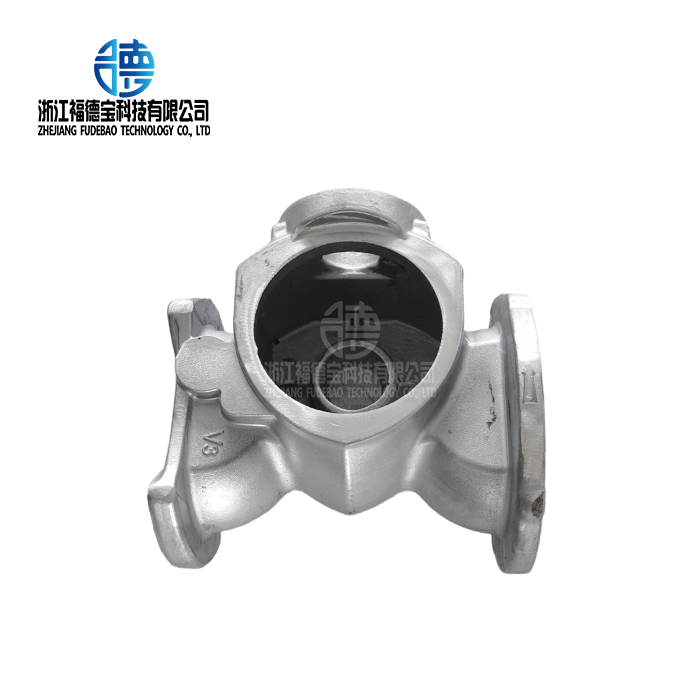

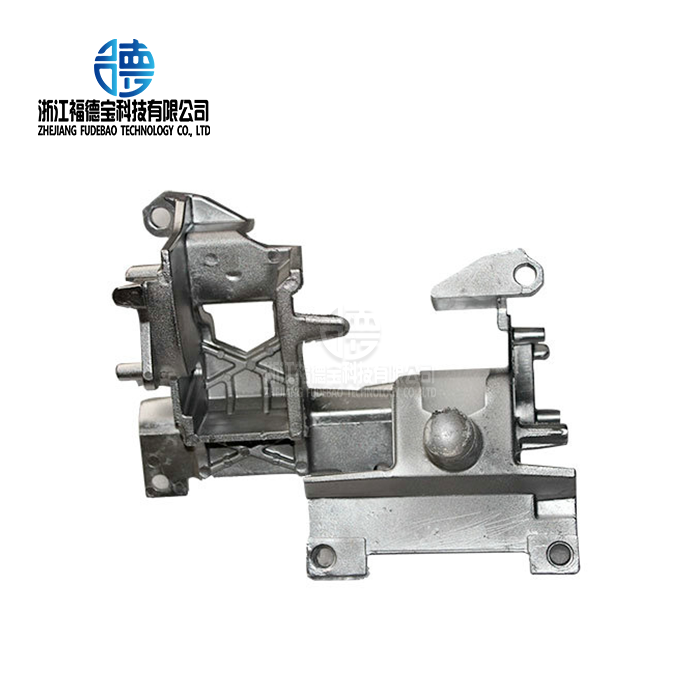

OEM low pressure casting services for custom aluminum parts help companies in the automobile, industrial gear, electrical, and aircraft industries make high-quality parts. This special casting method makes high-quality metal parts that are very accurate in their measurements and have strong structures. Controlled pressure is used in low pressure casting to fill molds slowly, which gets rid of turbulence and reduces porosity flaws. As a result, the parts are light, strong, and meet strict OEM requirements while still being cost-effective for large production runs.

Understanding OEM Low Pressure Casting for Modern Manufacturing

Precision, dependability, and speed are all things that are needed in making. OEM relationships in low pressure casting are now necessary for businesses that need unique metal solutions. During this process, light pressure is applied to liquid aluminum to make sure that the mold is completely filled without any air bubbles or turbulence.

Some benefits of low pressure casting are a better surface finish, less waste, and better mechanical qualities. The controlled filling process makes parts with walls that are all the same thickness and better structural stability. When choosing manufacturers for important parts, engineering managers and buying directors look for companies that offer these benefits.

Modern low pressure casting tools have tracking systems that work in real time and improved automation. These advances in technology make quality control more uniform and cut down on run times. This method works especially well for complicated shapes that need to be made with very tight specs and smooth surfaces.

Fudebao Technology's Manufacturing Excellence in Aluminum Casting

Through decades of specialized experience, Zhejiang Fudebao Technology Co., Ltd. has become a top aluminum manufacturer. Our industrial skills are very broad and cover the whole production cycle, from melting to finishing. We've successfully moved from working with middlemen to working directly with foreign names like ESS energy storage systems and American HAAS automation.

There are high-speed machining centers, CNC lathes, and state-of-the-art low pressure casting machines in our building. With this combined method, you can get everything from rough casts to finished parts in one place. We keep the quality of our machining at ±0.05mm, which meets the high standards needed for precise parts in cars and housings for medical equipment.

Throughout our production process for low pressure casting, quality control methods make sure that the products are always the same. A lot of advanced measuring tools are used to carefully check each casting. Our team knows how important it is for tier-1 providers and OEM uses to have accurate measurements. For military and security uses, we provide full PPAP documents and keep full tracking.

At our plant, the low pressure casting method uses high-tech cooling devices and tracking of parameters. This attention to detail cuts down on casting flaws and improves cycle efficiency. Our engineering team works closely with clients during mold creation to make sure the best plan for making is used.

Comprehensive Customization Solutions for Diverse Industries

It is possible to customize many aspects of the design and production of a component. Changes to the physical form are made to meet specific size needs, wall thickness changes, and complicated internal shapes. Our engineers use software for casting simulations to make sure that the design factors are perfect before production starts.

Different applications have different speed needs that can be met by functional modifications. For automotive housings to work, they need certain fixing and connection points. Parts of industrial tools need to be able to handle more heat and be made of stronger materials. For electrical uses, precise conductivity and rust protection qualities are needed.

Choosing the right material is a very important part of customizing. We work with different metal types that are best for different kinds of tasks. High-strength metals are used in aircraft, and corrosion-resistant alloys are used in naval settings. For each material choice, mechanical qualities, machinability, and surface treatment suitability are taken into account.

Surface cleaning choices can improve both how something looks and how well it works. Anodizing protects against rust, and powder finishing lets you choose the color. Tight tolerances are possible on important areas thanks to precision cutting. Our casting skills work perfectly with these finishing steps.

Branding customization includes adding logos, part naming systems, and labels for easy recognition. We can use a number of writing methods, such as laser etching and stamping. Compliance standards get a lot of attention, especially in businesses that are controlled, like medical products and aircraft.

Leveraging ODM Advantages for Product Innovation

Original Plan Manufacturing relationships let people work together to make a product, from the idea stage to mass production. Our engineering team has a lot of experience optimizing designs for low pressure casting. During the research process, we look for ways to cut down on weight, save money, and improve performance.

Comprehensive application research is the first step in working together on a design. Knowing the load requirements, the surroundings, and the assembly limitations helps with choosing the right materials and making the best shapes. Our experts have come up with other ideas that take advantage of the unique benefits of the low pressure casting process.

Prototype development accelerates product validation timelines. Before committing to production tools, we make small amounts to try and make sure they work. This method of working in small steps lowers the risks of development and makes sure that the end designs meet all performance standards.

Tooling design knowledge is very important to the success of a project. Complex core systems and multi-cavity setups are part of the mold creation services we offer. We get the best fill patterns and physical stability by optimizing gate systems and cooling channels.

Through ODM agreements, chances to combine technologies appear. We keep up with changes in the industry, such as efforts to make things lighter, new materials, and automated production. This information is useful for people who want to get ahead in their own markets.

Streamlined Manufacturing Process Excellence

The first step in our customized process is a thorough study of the application and a list of its requirements. Engineering managers, quality teams, and technical buying experts are all involved in the first discussions. To make full project plans, we look over models, specs, and performance requirements.

After the original study, best practices for low pressure casting are used in design improvement. Our team checks the shape, evenness of the wall thickness, and draft angles. Before making the tools, casting modeling checks the fill patterns and finds places where defects might happen.

Mold creation is an important project milestone. We make fine tools by using our advanced machining skills. Quality control methods make sure that the required surface finish and precision of measurements are met. Mold testing confirms how well the product will work in real production circumstances.

Setting up the quality system and optimizing the parameters are part of the production planning. The factors for low pressure casting are carefully calibrated to make sure that the products are always the same. The inspection methods are in line with what the customer wants and what the industry norms are. Traceability and quality approval needs are met by documentation tools.

Consistent quality and shipping performance are kept up by ongoing production help. Regular quality tests check that the process is stable and that the dimensions are met. We offer expert help for making changes to designs and finding ways to make output more efficient.

Strategic Benefits for Manufacturing Partners

Working with skilled low pressure casting suppliers gives you many benefits over other companies. Design tuning and gains in factory speed can lead to chances to cut costs. Our combined powers get rid of the need for multiple providers to coordinate with each other.

Our complete process control tools make sure that the quality is always the same. Statistical process tracking finds patterns before they have an effect on the quality of the result. Preventive repair plans make sure that equipment works well and stays the same size.

Flexibility in the supply chain allows for changes in production rates and schedules. Our planning for capacity takes into account both small numbers for prototypes and large production runs. Inventory management services lower the amount of operating capital that is needed and make sure that materials are always available.

Throughout the lifespan of an object, technical knowledge adds value. Our tech team is always there to help with efforts to improve designs and cut costs. We keep an eye on changes in the industry and suggest ways to make things better that help our partners.

Support for the global market includes helping with regulations and coordinating licensing. We know about the rules and standards for quality that apply around the world. Our methods for keeping records help customers with reports and certifications in many areas.

Conclusion

The future of making metal products depends on working with OEM providers who have a lot of knowledge and know both the technical needs and the market needs. Because Fudebao Technology is dedicated to quality and innovation and has a wide range of low pressure casting skills, we are the perfect production partner for tough jobs.

Our combined method, which includes everything from optimizing the design to delivering the finished parts, makes supply chain management easier and guarantees great results. Modern producers need dependability, which can be found in high-tech tools, skilled engineers, and tried-and-true quality control systems.

To be successful in today's markets, you need business partners who can change with the times while keeping quality standards high. Our knowledge of low pressure casting, along with our wide range of customization options, makes for a solid basis for long-term relationship success.

FAQs

What are the main reasons why low pressure casting is better than other ways to cast aluminum?

Compared to gravity casting, low pressure casting has a smoother surface, fewer holes, and more accurate measurements. The controlled filling process gets rid of turbulence, which makes the parts stronger and keeps the wall width the same. This method also cuts down on waste and makes it possible to make complicated shapes with tight limits.

How does Fudebao Technology make sure that the low pressure casting method is quality controlled?

We use full quality control systems that include advanced inspection tools, real-time tracking of parameters, and statistical process control. Each casting is checked for accuracy in terms of its dimensions and its material properties. Our quality control system meets PPAP paperwork standards and gives full tracking.

What types of aluminum metals can be used for low pressure casting?

We work with different kinds of aluminum alloys, such as A356, A380, and special mixes made for certain uses. Which alloy to use relies on its mechanical properties, its ability to fight rust, and its cutting properties. Based on application research and performance factors, our engineering team suggests the best materials.

Partner with Fudebao Technology for Superior Low Pressure Casting Solutions

OEMs in the automotive, industrial equipment, and aircraft industries need low pressure casting providers they can trust and who understand the difficulties they face. Fudebao Technology creates great results by combining advanced manufacturing skills with full tech support.

Our history of working with global names shows that we are dedicated to quality and dependability. We know how important it is for today's competitive markets that measurements are correct, materials are good, and deliveries are on time. We are a reliable low pressure casting maker, and we have the skills and tools you need to make your project a success.

Whether you need to make a sample, production tools, or a lot of products, our combined powers will make your supply chain run more smoothly and ensure consistent quality. Our team of engineers is ready to work with you on your next project involving custom metal casting.

Are you ready to find out how our knowledge of low pressure casting can help your projects? Email us at hank.shen@fdbcasting.com to talk about your needs and learn more about the benefits of Fudebao Technology.

References

Campbell, J. "Complete Casting Handbook: Metal Casting Processes, Metallurgy, Techniques and Design." Second Edition, Butterworth-Heinemann, 2015.

American Foundry Society. "Aluminum Casting Technology Handbook." Des Plaines: AFS, 2018.

Kaufman, J.G. and Rooy, E.L. "Aluminum Alloy Castings: Properties, Processes, and Applications." ASM International, 2004.

Tillova, E. and Chalupova, M. "Low Pressure Casting Technology for Automotive Applications." Materials Science Forum, Vol. 782, 2014.

International Organization for Standardization. "ISO 9001:2015 Quality Management Systems - Requirements." Geneva: ISO, 2015.

SAE International. "SAE J1739: Potential Failure Mode and Effects Analysis in Design (Design FMEA), Potential Failure Mode and Effects Analysis in Manufacturing and Assembly Processes (Process FMEA)." Warrendale: SAE, 2021.

_1756346043433.webp)

_1756348300182.webp)

_1756349071334.webp)