Top Copper Casting Manufacturers for Industrial Use

2026-01-19

When assessing leading producers of copper castings for industrial use, procurement specialists need to take into account businesses that provide outstanding quality, dependability, and technological know-how. Leading producers in the automotive, aerospace, electrical, and heavy equipment industries are excellent at creating copper castings that satisfy exacting industry requirements. To guarantee reliable performance in demanding applications, these specialty foundries integrate cutting-edge casting methods with extensive quality control systems. The most trustworthy copper casting suppliers uphold certifications like ISO 9001, AS9100, and IATF 16949, which attest to their dedication to quality and adherence to regulations.

Understanding Copper Castings and Their Industrial Relevance

Copper castings are precisely designed parts made using advanced foundry techniques that shape molten copper alloys into intricate shapes. Because of their outstanding mechanical strength, outstanding electrical qualities, great thermal conductivity, and superb corrosion resistance, these components are highly sought across a wide range of industries. Because of these qualities, copper castings are essential in situations where operational safety and cost-effectiveness are strongly correlated with performance dependability.

Common Casting Methods and Production Techniques

The most popular technique for creating copper components is still sand casting, especially for bigger parts and intricate geometries. Using carefully prepared sand mixes that can tolerate the high temperatures needed for copper alloy casting, molds are made in this method. For complex parts used in precision applications, investment casting—also referred to as lost-wax casting—offers excellent surface finishes and dimensional accuracy.

Pattern generation usually starts the manufacturing pipeline, which is then followed by mold preparation and metal melting processes. Every step incorporates quality control procedures, such as temperature monitoring, dimensional verification, and chemical composition analysis. Modern foundries use sophisticated furnace systems that may minimize flaws, maintain accurate temperature control, and guarantee constant alloy characteristics.

Performance Characteristics in Industrial Applications

Copper's thermal conductivity qualities are advantageous to heat exchangers, allowing for effective energy transfer in industrial processing facilities, HVAC systems, and power generating machinery. Copper's superior conductivity is used in electrical connections and motor parts to reduce energy losses and guarantee dependable electrical transmission. Copper's inherent antibacterial qualities and resistance to corrosion are used in marine applications to increase equipment longevity in challenging saltwater conditions.

In a variety of applications, the material's intrinsic qualities help to lower maintenance needs and increase service intervals. For parts subjected to corrosive environments, high-temperature operations, and applications needing exceptional dimensional stability over prolonged working periods, industrial equipment makers are increasingly specifying copper castings.

Top Copper Casting Manufacturers: Criteria and Selection Factors

A thorough assessment of many crucial elements that directly affect product quality, delivery dependability, and the success of a long-term cooperation is necessary when choosing a copper casting company. A manufacturer's dedication to uniform manufacturing standards and continual improvement techniques is mostly shown by their quality certifications. While industry-specific certifications like AS9100 for aerospace applications or IATF 16949 for automotive components indicate particular competence, ISO 9001 certification shows adherence to quality management systems.

Regional Manufacturing Capabilities and Specializations

High-precision applications demanding exacting tolerances and thorough documentation for copper castings are usually where North American manufacturers shine. These factories often focus on aerospace and military components, where certification and traceability are crucial. European foundries are well known for their cutting-edge alloy creation skills and sophisticated metallurgical knowledge, especially in the fields of maritime and renewable energy.

Asian producers are well known for their ability to produce large quantities of goods at low costs while upholding quality standards. To compete in international markets, several of these plants have made significant investments in automation and cutting-edge quality control technologies. Manufacturers differ greatly in their production capability; some concentrate on high-volume manufacturing with optimal lead times, while others specialize on prototype and low-volume production.

Technical Support and Value-Added Services

The most prosperous copper casting collaborations go beyond simple manufacturing services to provide thorough technical assistance at every stage of the product development process. Prominent manufacturers assist clients in optimizing component shapes for enhanced castability and performance by offering design advice services. When choosing the right alloy compositions for certain operating conditions and performance requirements, metallurgical knowledge becomes very useful.

Supply chain dependability includes both the manufacturer's capacity to maintain consistent quality when growing operations and on-time delivery performance. Project performance is greatly influenced by efficient communication methods, which include proactive problem solving and frequent progress reports. Premium vendors are distinguished from basic casting providers by their after-sales service, which includes warranty coverage and technical help during product integration.

Comparing Copper Castings with Alternative Materials and Alloys

Procurement experts may make well-informed selections based on particular application requirements and performance targets by knowing the relative benefits of copper castings vs other materials. For certain operational circumstances, budgetary restrictions, and performance requirements, each material category provides unique qualities that can be ideal.

Material Performance Comparisons

Compared to copper alloys, aluminum castings provide superior strength-to-weight ratios and corrosion resistance at cheaper prices. However, copper has far better thermal and electrical conductivity qualities than aluminum, which limits aluminum's usefulness in electrical and heat transfer applications. Although steel castings are stronger and more resilient to wear, they don't have the conductivity or corrosion resistance of copper.

Compared to pure copper, bronze alloys with copper as the predominant component provide better strength and wear resistance while retaining high conductivity qualities. These alloys work especially well in maritime conditions and bearing applications where corrosion resistance and strength are essential. Although brass alloys are very machinable and have a beautiful look, they are often weaker than other copper alloys.

Copper Alloy Selection Guidelines

One of the most often requested copper casting alloys is C93200 bearing bronze, which provides outstanding bearing qualities and exceptional machinability for applications involving rotating machinery. The lead concentration of this alloy maintains sufficient strength for applications involving modest loads while offering good bearing qualities. Because of its remarkable strength and resistance to corrosion, C95400 aluminum bronze is perfect for high-stress applications in corrosive environments, such as marine propellers and valve components.

Operating temperature ranges, corrosive exposure, mechanical loading conditions, and electrical requirements should all be taken into account throughout the selection process. When choosing an alloy, procurement teams may assure optimum performance characteristics by consulting with metallurgical specialists. To find the most cost-effective option across the component's operating lifespan, cost considerations must weigh material costs against anticipated service life and maintenance needs.

Procurement Process: How to Buy Copper Castings Efficiently?

A methodical approach to order management, specification formulation, and supplier assessment is necessary for the efficient procurement of copper castings. Organizations may choose the best sourcing strategy based on their unique needs and operational restrictions by being aware of the many procurement channels that are accessible.

Supplier Evaluation and Verification Procedures

Facility audits to analyze production capacity, quality control systems, and manufacturing capabilities are the first step in a thorough supplier evaluation. An evaluation of financial stability lowers supply chain risks and guarantees the long-term survival of partnerships. Reference checks with current clients provide insightful information on real performance indicators, delivery dependability, and problem-solving skills.

Verification of certification should include both industry-specific criteria and quality management systems. Process flow diagrams, inspection protocols, and statistical process control data must all be included in the documentation review. In order to satisfy project requirements, technical capacity evaluation evaluates the engineering support resources, testing apparatus, and metallurgical knowledge that are available.

Pricing Structure and Lead Time Management

Raw material composition, alloy complexity, casting technique requirements, and finishing demands are some of the variables that affect copper casting costs. While geometric complexity influences manufacturing time and tooling requirements, component weight directly affects material prices. Quotation requests should include the additional expenses associated with surface treatments, quality testing, and secondary machining processes.

Depending on the casting technique, component complexity, and required production volume, lead time predictions vary greatly. Compared to die casting, sand casting usually takes less time for tool development; nevertheless, complicated geometries may demand longer production cycles. Although investment casting demands longer cycles for pattern creation and production, it offers better surface finishes and dimensional precision.

Sustainable Sourcing Considerations

The need for recycled copper content in casting applications has grown as environmental responsibility has gained more attention. Today, a lot of manufacturers provide certified recycled material choices that lessen their environmental effect while maintaining performance requirements. Environmental management system compliance and sustainability certifications are becoming more and more crucial considerations when choosing suppliers.

The overall sustainability aims of the supply chain for copper castings are aided by waste reduction programs and energy-efficient production techniques. Regional sourcing techniques for transportation optimization might possibly improve delivery performance while drastically lowering carbon emissions. Life cycle evaluations aid in measuring how production procedures and material selections affect the environment.

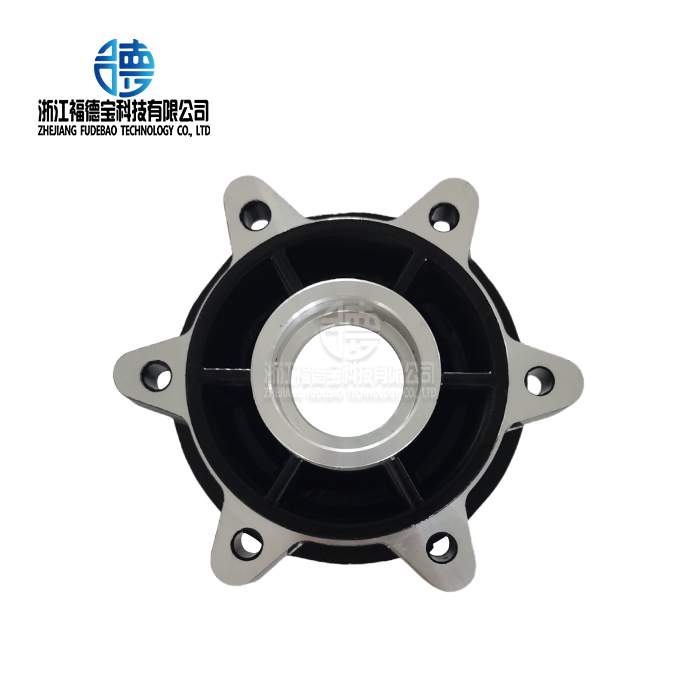

Company Introduction and Product & Service Information

With a focus on copper alloys, aluminum alloys, and stainless steel components for demanding industrial applications, Zhejiang Fudebao Technology Co., Ltd. has distinguished itself as a leading leader in precision metal casting and machining. Our extensive production capabilities support a variety of industries where accuracy and dependability are critical, such as automotive, industrial equipment, machinery manufacture, and aerospace applications.

Advanced Manufacturing Capabilities

Modern technology such as precision CNC lathes, low-pressure casting machines, high-speed machining centers, and sophisticated die casting systems are housed in our state-of-the-art facility. We can provide comprehensive solutions because to this integrated approach, which includes everything from initial casting to final machining and surface treatment procedures. Our quality control solutions fulfill the rigorous standards of medical device applications and automotive precision components by maintaining dimensional accuracy up to ±0.05mm.

Our dedication to quality and dependability is shown by the company's transition from intermediary collaboration to direct supply relationships with well-known worldwide brands, such as American HAAS automated machine tools and ESS energy storage systems. This development demonstrates our commitment to setting the standard for metal foundry operations.

Comprehensive Service Portfolio

Beyond simple production, we also provide technical advice, assistance with design optimization, and adaptable order management features as value-added services. During the design stage, engineering teams work closely with clients to optimize component shapes for better performance and manufacturing capabilities. Various client needs and delivery dates are supported by expedited shipping choices and personalized packing solutions.

Complete traceability documentation, statistical process control, and thorough inspection methods are all included in quality management systems. Energy-efficient production methods and possibilities for recycled material are part of our dedication to sustainable manufacturing practices. Because of these qualities, Fudebao Technology is a perfect partner for businesses looking for dependable, superior copper casting solutions.

Conclusion

It is crucial to carefully consider technical prowess, quality assurance protocols, and service offerings that correspond with project specifications when choosing a copper casting company. Reliable delivery performance, extensive support services, and outstanding manufacturing skills are all components of the most successful collaborations. Among possible suppliers, quality certificates, metallurgical expertise, and demonstrated performance in related sectors are important differentiators. Long-term partnerships with manufacturers that exhibit reliable performance, technological innovation, and attentive customer care are advantageous to organizations. Better product quality, lower supply chain risks, and increased operational efficiency are all benefits of investing in rigorous supplier assessment procedures.

FAQs

Which sectors make the largest use of copper castings?

Because of copper's remarkable conductivity, copper castings play vital roles in a variety of industrial sectors, with the electrical and power generating industries using the most. Copper alloys are required by automakers for specific engine parts, heat exchangers, and electrical components. Copper's ability to withstand corrosion is crucial for propellers, valves, and hull fittings in marine applications. Pumps, compressors, and heat transfer devices are all made using copper castings by industrial machinery makers.

How can I choose the right copper alloy for my use case?

Specific performance requirements, such as operating temperature, exposure to corrosive environments, mechanical loading circumstances, and electrical conductivity requirements, influence the choice of alloy. While C95400 aluminum bronze offers exceptional strength and corrosion resistance for maritime conditions, C93200 bearing bronze shines in applications involving rotating machinery. Cost-effectiveness and the best performance characteristics are guaranteed when metallurgical specialists are consulted throughout the selection process.

How long do bespoke copper casting orders usually take to complete?

Lead times vary greatly depending on the order amount, component complexity, and casting technique. Investment casting may take 6–8 weeks because of the intricacy of the design, while sand casting projects usually take 4-6 weeks for tooling development and start production. Reduced lead times per item after initial tooling completion are often advantageous for high-volume manufacturing runs. Priority scheduling and premium pricing may be used to fulfill urgent requests.

How can I confirm the dependability and quality of providers of copper casting?

Facility audits, certification evaluations, and reference checks with current clients are all part of thorough supplier verification. Systematic techniques to quality control are indicated by quality management certifications like ISO 9001. Evaluations of production capacity and financial stability contribute to the long-term success of partnerships. Metallurgical testing and sample part assessment provide concrete proof of production capacity and quality requirements.

Partner with Fudebao Technology for Premium Copper Casting Solutions

Find out how the sophisticated copper casting skills of Fudebao Technology might improve the outcome of your next project. Delivering precise copper castings that satisfy the exacting specifications of industrial, automotive, and aerospace applications is our skilled engineering team's area of expertise. We guarantee dimensional accuracy up to ±0.05mm while keeping competitive lead times thanks to our state-of-the-art production equipment and extensive quality control procedures. To discuss your unique needs and get thorough technical advice for your next projects, get in touch with our copper castings manufacturing team at hank.shen@fdbcasting.com.

References

American Foundry Society. "Copper Alloy Casting Handbook: Properties and Applications in Industrial Manufacturing." Technical Publication Series, 2023.

International Copper Association. "Industrial Applications of Copper Castings: Performance Standards and Quality Guidelines." Research Report on Metal Casting Technologies, 2023.

ASM International. "Copper and Copper Alloys: Casting Processes and Material Selection Guide." Handbook of Industrial Metal Processing, 2022.

Society of Manufacturing Engineers. "Advanced Casting Technologies for Copper Alloys in Automotive and Aerospace Applications." Manufacturing Engineering Quarterly, 2023.

Materials Research Institute. "Comparative Analysis of Copper Casting Methods: Sand Casting vs Investment Casting Performance Study." Journal of Industrial Materials Science, 2022.

Global Foundry Association. "Best Practices in Copper Alloy Procurement: Supplier Selection and Quality Assurance Standards." Industrial Procurement Guidelines, 2023.

YOU MAY LIKE

_1756346205762.webp)

_1756346259673.webp)

_1756349002499.webp)