Selecting a Qualified Low Pressure Casting Supplier

2026-01-19

A crucial choice that directly affects product quality, production costs, and delivery schedules is choosing a certified low pressure casting provider. For industrial, automotive, and aerospace applications, choosing a supplier is essential since low pressure casting technology provides better material integrity and dimensional precision than traditional casting techniques. Manufacturers may form alliances that promote operational excellence and long-term success by being aware of the important assessment criteria and procurement ramifications.

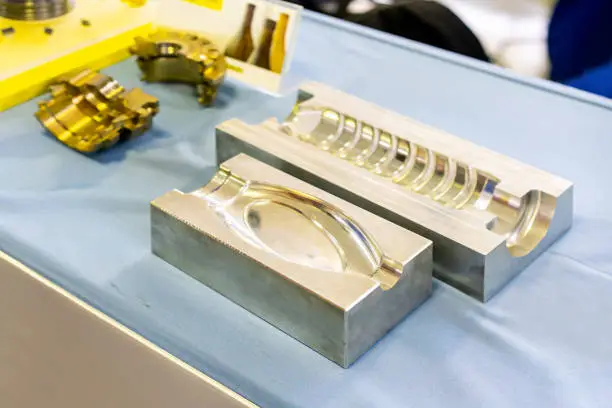

Understanding the Low Pressure Casting Process and Its Procurement Implications

A complex manufacturing process known as low pressure casting involves the controlled flow of molten metal into molds at pressures usually between 0.1 and 0.7 bar. Turbulence is eliminated while filling in this regulated environment, producing components with low porosity and superb surface finish quality. The method is especially useful for precision applications as it is excellent at creating intricate shapes with close tolerances.

Material Selection and Alloy Compatibility

Because of their superior strength-to-weight ratio and resistance to corrosion, aluminum alloys are often used in low pressure casting applications. AlSi7Mg, A356, and A357 are common alloy grades that each have unique mechanical qualities appropriate for certain uses. The capacity of suppliers to maintain consistent metallurgical qualities across production runs and their proficiency in handling a variety of alloys must be confirmed by procurement teams.

Process Advantages Over Alternative Methods

Through directed solidification and a lower inclusion content, low pressure procedures outperform gravity casting in terms of mechanical qualities. Low pressure techniques give greater dimensional stability and less internal stress, while die casting offers quicker cycle times. Procurement experts may choose suppliers whose skills match certain project objectives and quality expectations by being aware of these trade-offs.

Production Scalability Considerations

Supplier capacity and price structures are impacted by the significant capital expenditure required for low pressure casting equipment. Suppliers can handle different production quantities while maintaining constant quality standards if they have several casting stations, automated handling systems, and sophisticated furnaces. Throughout product lifecycles, dependable supply chain performance is ensured by evaluating supplier infrastructure.

Core Criteria for Selecting a Qualified Low Pressure Casting Supplier

Setting up transparent performance standards and assessment frameworks is the first step in choosing a supplier successfully. Quality certifications are essential screening criteria; industry-specific certifications such as IATF 16949 show expertise in the automotive sector, while ISO 9001 provides baseline quality management requirements. AS9100 certification and strict traceability procedures are usually needed for aerospace applications.

Technical Capabilities Assessment

Advanced process monitoring and control systems are integrated into contemporary low pressure casting processes. To guarantee reliable outcomes, sophisticated providers make use of automated mold handling, pressure feedback loops, and real-time temperature monitoring. In order to determine if a supplier can fulfill strict requirements, technical skills are evaluated by looking at equipment age, maintenance procedures, and process control paperwork.

Production Capacity and Flexibility

Suppliers must show that they have the ability to manage anticipated volumes and fulfill delivery obligations. Important things to think about are:

- Annual production capacity across different alloy types

- Capacity to increase output in response to changes in demand

- Capacity to store mold and efficiency of changeover

- Capabilities for secondary processing such as surface treatments and machining

These elements have a direct impact on supplier dependability and their capacity to foster company expansion without sacrificing delivery efficiency or quality.

Quality Management Systems

Incoming material inspection, process monitoring, and final product verification are all components of strong quality systems. Prominent vendors use statistical process control, keep thorough records, and provide in-depth inspection reports that include dimensional analysis. Assessing the breadth of quality management exposes a supplier's dedication to defect avoidance and ongoing development.

Navigating Low Pressure Casting Service and Pricing Structures

Understanding the many cost factors affecting the final product's cost is necessary for pricing transparency. The cost of materials usually accounts for 40–60% of the entire cost of casting, and the price of aluminum is dependent on changes in the worldwide market. Geographical location and automation level have a substantial impact on labor costs, while tooling amortization distributes mold development expenses across production volumes.

Lead Time Management

Lead times for low pressure casting include production scheduling, process development, tooling fabrication, and mold design. Skilled vendors communicate milestone progress throughout development stages and keep meticulous project schedules. Improved production planning and the ability to spot any bottlenecks before they affect delivery schedules are made possible by an understanding of lead time components.

Minimum Order Quantities and Flexibility

Based on setup expenses, material handling effectiveness, and production schedule limitations, suppliers determine minimum order numbers. Inventory management may be maximized while maintaining capacity allocation by negotiating flexible ordering agreements, such as blanket orders with timed releases. Consolidation services are provided by progressive suppliers, who combine many part numbers into a single shipment to increase logistical effectiveness.

Geographic Considerations and Supply Chain Risk

Transportation expenses, delivery dependability, and communication efficiency are all impacted by the location of the supplier. Advantages of closeness from regional suppliers include lower shipping costs and quicker turnaround times for urgent needs. Global sourcing, however, could provide financial advantages or access to specialist skills that aren't accessible locally. To maximize cost and risk management, balanced supplier portfolios often comprise both domestic and foreign partners.

Ensuring Quality and Optimizing Production with Your Low Pressure Casting Supplier

In order to ensure quality in low pressure casting, it is necessary to comprehend frequent flaws and their underlying causes. The most common problem is still porosity, which is often brought on by contaminated materials, inadequate degassing, or poor gating design. Cold shuts happen when metal streams don't fuse correctly, usually due to fluctuations in mold temperature or insufficient filling pressure.

Defect Prevention Strategies

During the design stages, suppliers and customers work together as part of proactive quality control. Many quality problems are avoided before production starts by developing efficient gating systems, optimizing component shape, and determining suitable wall thickness ratios. Strong engineering assistance enables suppliers to see possible issues early and suggest design changes that preserve functionality while enhancing manufacturability.

Process Innovation and Efficiency Improvements

Cutting-edge suppliers in low pressure casting consistently make investments in process enhancements that enhance both cost and quality performance. While electromagnetic stirring enhances alloy homogeneity, vacuum-assisted low pressure casting further lowers porosity. Automated mold preheating and metal transfer systems reduce human error and increase production run uniformity.

Environmental Compliance and Sustainability

Environmental restrictions pertaining to energy usage, waste management, and emissions are becoming more and more strict for modern casting processes. Suppliers who use energy-efficient melting technologies, closed-loop recycling systems, and extensive waste reduction initiatives show that they are dedicated to sustainable manufacturing methods. These programs often result in long-term financial benefits while advancing business sustainability goals.

Company Introduction & Our Low Pressure Casting Solutions

With a focus on precision metal casting and machining solutions for international markets, Zhejiang Fudebao Technology Co., Ltd. is a leading company in China's aluminum foundry sector. Our extensive capabilities include casting stainless steel, copper alloy, and aluminum alloy, meeting the needs of the automotive, industrial equipment, machinery, and aerospace industries.

Advanced Manufacturing Infrastructure

Modern machinery such as CNC lathes, low pressure casting machines, die casting systems, and high-speed machining centers are housed at our facilities. The whole production process, including melting, casting, finishing, and surface treatment, is covered by this integrated technique. We satisfy the exacting specifications of medical equipment housings and automotive precision components by maintaining machining accuracy of up to ±0.05mm.

Global Partnership Success

Because of our dedication to quality, we have direct supply connections with well-known worldwide companies, such as ESS energy storage systems and American HAAS automated machine tools. These collaborations show that we can reliably satisfy strict specifications and delivery deadlines while validating our technological prowess and quality control procedures.

Comprehensive Service Portfolio

We remove the hassle of coordinating many vendors by providing full one-stop delivery from blank castings to completed components. Precision machining, surface treatments, and assembly services are among our integrated capabilities, which provide clients simplified supply chain solutions and lower overall procurement costs.

Conclusion

It is necessary to systematically assess technical skills, quality systems, and operational dependability when choosing a certified low pressure casting provider. Making educated supplier selections is made possible by comprehending the principles of the casting process, defining precise selection criteria, and assessing price structures. The success of long-term partnerships is ensured by quality assurance procedures and ongoing improvement projects. Due to our extensive capabilities and solid track record, Fudebao Technology is the perfect partner for demanding casting applications in a variety of sectors.

FAQs

What details should I provide in my request for a quotation for low pressure casting?

Complete technical specifications, such as part drawings with dimensions and tolerances, material needs that include alloy grade and temper condition, yearly volume predictions, and expected delivery timelines, are necessary for accurate bids. Quality standards and inspection needs, packing or shipping criteria, and secondary processing requirements like machining or surface treatments are additional factors to take into account.

How can I confirm the qualifications and quality certifications of a supplier?

Requesting copies of the most recent certifications, doing facilities audits or virtual tours, looking at case studies and customer references, and analyzing quality manual paperwork are all part of the verification process. In addition to giving sample parts that prove their production accuracy and surface finish quality, many suppliers also give capability videos that highlight their machinery and procedures.

What typical problems arise during the procurement of low pressure castings, and how may they be resolved?

Communication obstacles, inconsistent quality, and unpredictable lead times are common problems. Establishing precise project schedules with milestone tracking, putting in place strong quality agreements with explicit acceptance criteria, and maintaining consistent communication procedures across production cycles are all necessary to address these issues. These risks are considerably reduced when vendors with extensive quality processes and a track record of success are chosen.

Partner with Fudebao Technology for Superior Low Pressure Casting Solutions

With decades of manufacturing experience and state-of-the-art production equipment, Fudebao Technology provides outstanding low pressure casting solutions. For the most demanding applications, we guarantee consistent results thanks to our ISO-certified facility and extensive quality control systems. To discuss your unique needs and learn how our integrated production capabilities may improve your supply chain, get in touch with hank.shen@fdbcasting.com.

References

American Foundry Society. "Low Pressure Casting Technology and Applications." Casting Process Guidelines, 2023.

International Journal of Metalcasting. "Quality Control Methods in Low Pressure Aluminum Casting." Volume 17, Issue 3, 2023.

ASM International. "Aluminum Casting Technology: Process Selection and Quality Optimization." Materials Engineering Handbook, 2022.

Society of Automotive Engineers. "Automotive Casting Specifications and Supplier Qualification Standards." SAE Technical Paper Series, 2023.

Manufacturing Engineering Society. "Procurement Best Practices for Metal Casting Suppliers." Industrial Supply Chain Management, 2022.

Foundry Management & Technology Magazine. "Advanced Low Pressure Casting Techniques and Equipment." Industry Analysis Report, 2023.

_1756352625880.webp)

_1756352822273.webp)