Low pressure casting is a new and revolutionary way to make things that changes how car wheels are made by giving them the high level of structural strength and precise dimensions that modern car makers expect. This advanced aluminum casting method uses controlled pressure to push liquid metal into molds. This makes wheel parts that are light but strong and meet strict car performance standards. The process solves important problems in the industry, like lowering weight, making better use of materials, and making sure that the standard of the output is always the same, all while keeping the costs low, which is important for large-scale production settings.

Understanding Low pressure casting Technology in Automotive Manufacturing

The car business is still moving toward parts that are lighter and harder so that vehicles use less gas and perform better. Low pressure die casting has become one of the most important methods for making aluminum alloy wheels that meet these strict standards.

Controlled pressure, usually between 0.1 and 1.0 bar, is used in this manufacturing process to push molten aluminum through a tube and into the mold hole. This controlled filling process, unlike traditional gravity casting, gets rid of turbulence and lowers rust. This makes the metal's features and surface quality better.

Automobile companies today are becoming more and more aware of how useful this casting method is for making wheels that are both very strong and very light. This method works especially well with aluminum metals like A356, which have the best mix of being easy to cast, having good mechanical qualities, and not rusting.

As the use of electric vehicles grows, market trends show that there is a greater need for new methods for making wheels. To get the most out of their batteries, electric cars need parts that are very light. This makes aluminum casting options more important than ever for auto OEMs and tier-1 suppliers.

Better Advantages of Low pressure casting for Making Wheels

Using low pressure casting technology has benefits that go far beyond its ability to make things. This method is always chosen by engineering managers and buying directors because it improves performance in a number of ways that can be measured.

Here are the core advantages that make this technology indispensable for modern wheel manufacturing:

Better Structural Integrity: The controlled filling process makes the wheel's grain structure regular, so it doesn't have any weak spots like gravity-cast wheels do. This makes wheels that work consistently even in the worst driving situations and go above and beyond safety standards.

Excellent Use of Materials: Advanced pressure control makes sure that the mold is fully filled with very little extra metal, so there is very little material loss. This speed leads to big cost saves in settings with a lot of production, and it also helps with environmental efforts.

Better Surface Finish: The gentle filling action gets rid of surface flaws and holes, leaving wheels with smooth finishes that don't need much post-processing. This benefit cuts down on production time and improves the look of the finished product.

Precise Dimensional Accuracy: Applying pressure in the same way every time makes sure that the dimensions are always within or above the standards set by the car industry. Quality teams like that there is less difference because it makes inspections easier and makes sure that the assembly is reliable.

These benefits take care of the main issues that vehicle buying pros have to deal with when they have to balance quality, cost, and shipping needs. This technology is especially useful for making wheels that meet the PPAP paperwork standards that are needed for OEM approval processes.

Quality Standards and Technical Excellence in Cast Wheel Production

To get uniform quality when making wheels for cars using low pressure casting, you have to pay close attention to the process factors and follow international standards. To get solid results that meet the needs of the car business, the casting process needs precise control of a number of factors.

Keeping an eye on the temperature is very important for making wheels that don't have any flaws. Keeping the metal at the right temperature during casting stops it from solidifying too quickly and stops it from getting too hot, which could damage its mechanical properties. Modern temperature tracking devices let changes be made in real time that keep things the same between production runs.

The shape of the mold is another important factor that affects the quality of the end product. Using the right gate systems and opening setups will keep the metal flowing smoothly and stop air from getting stuck, which could lead to porosity flaws. To get the best quality and cycle time, engineering teams have to carefully balance how fast the bottles are filled with how well they are controlled.

Following the ISO/TS 16949 guidelines makes sure that the production methods meet the quality standards for cars around the world. This license shows that the company is dedicated to the ongoing growth and organized quality management that car buyers expect from their providers.

Modern checking tools, like X-rays and coordinate measure machines, make it possible to check the quality of a product completely. These tools help find problems before they happen with goods, which supports the long-term dependability that car uses need.

Comparative Analysis: Low pressure casting Versus Alternative Methods

Purchasing managers can make better choices about manufacturing partnerships when they know how the different casting methods compare. Each method has its own benefits that depend on the needs of the program and the amount of production.

Gravity casting is cheaper at first, but the wheels it makes often have more holes in them and different mechanical qualities when compared to low pressure casting. When the filling process is not managed, it causes turbulence that introduces flaws, which makes it less ideal for high-performance car uses.

While high pressure die casting produces a smooth surface and accurate measurements, it takes a lot more money to be spent. Extreme forces also make it hard to choose the right materials and can cause internal stresses that affect how long something lasts.

Sand casting gives you a lot of options for making prototypes, but it doesn't give you the accuracy and smooth surface you need for production wheels. The method also makes more trash and needs a lot of cutting to get results that are good enough.

The best mix between quality and cost is found in low pressure aluminum casting. The modest forces used allow for good mechanical qualities while keeping the cost of the tools low. Because of these factors, it is especially good for middle to high-volume production needs that are common in the car industry.

Strategic Supplier Selection for Low pressure casting Excellence

Picking the right manufacturing partner has a big effect on how well the project goes and how much it costs in the long run. To make sure the supply chain works well, automotive OEMs and tier-1 suppliers have to look at possible partners based on a number of factors.

The amount of technology, the capacity of the tools, and the process control systems should all be part of a manufacturing capability review. Modern factories with automatic handling systems and real-time tracking can give car uses the precision and control they need.

A supplier's certification status shows how committed they are to quality management and constant growth. Partners with the right car certifications show that they know what the industry needs and how to ensure quality in a structured way.

As wheel designs get more complicated, being able to provide technical help for low pressure casting becomes more and more important. Suppliers that give design help, modeling services, and fast testing can cut down on development times and make products easier to make.

Logistics prices and the reliability of the supply chain are affected by where things are located. When it comes to contact and shipping costs, regional suppliers may be better, while global sellers may give you access to unique technologies or cost structures.

Conclusion

The perfect mix of quality, speed, and cost-effectiveness for current car wheel production is provided by low pressure casting technology. The controlled filling process makes wheels with better mechanical qualities while keeping the exact measurements that are needed for safety and performance. As the car industry continues to focus on fuel economy and lightweight design, this way of making things becomes more valuable for OEMs and suppliers looking for ways to stay ahead of the competition. This advanced casting technology will only work if it is put into use by producers with a lot of experience who know both the technical needs and quality standards.

FAQs

What kinds of metal alloys form the best wheels when made under low pressure?

Because it has a great strength-to-weight ratio, is easy to make, and doesn't rust, A356 aluminum alloy is the gold standard for making wheels for cars. This metal has silicon and magnesium added to it, which make it more fluid during casting and help the heat treatment process work better for better mechanical qualities.

How is controlling the pressure better than using gravity to get rid of casting flaws?

Controlled pressure filling gets rid of the swirling and trapped air that happen a lot in gravity casting. The steady flow of metal stops rusting and stops pores from forming. This makes wheels with better mechanical features and uniform quality throughout the casting process.

How well does low pressure casting work for making a lot of cars?

Of course. With today's automatic systems, turn times are on par with other casting methods, and quality levels stay high. The process works well for making a lot of cars and gives the uniformity needed to meet OEM shipping standards.

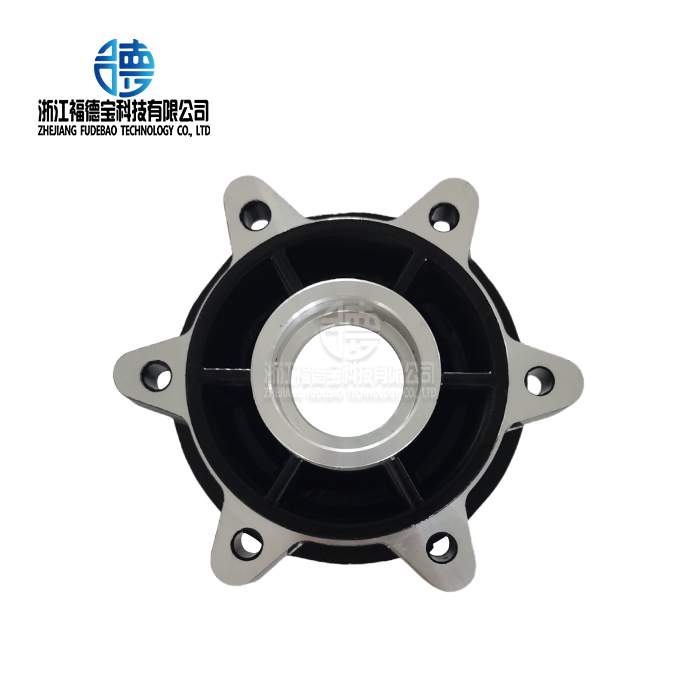

Fudebao Technology: Your Trusted Low pressure casting Manufacturer

Zhejiang Fudebao Technology has become a top aluminum manufacturer specializing in low pressure casting that works with automakers and tier-1 suppliers all over the world. Our full range of industrial services includes the whole process, from melting down raw materials to delivering finished parts.

Our building has high-tech machines like high-speed machining centers, CNC lathes, and cutting-edge low pressure casting machines that can make parts with precise specs of up to ±0.05mm. While supporting efficient production processes, this level of accuracy meets the demanding needs of car wheel uses.

We are experts at casting solutions for aluminum alloys, copper alloys, and stainless steel that are used in a wide range of industrial settings. We have a history of meeting strict quality and service standards because we have worked with foreign names like American HAAS robotic equipment.

Quality control is still very important to us, and we have a lot of checking tools and approved methods that make sure the results are always the same. Our team knows what kind of paperwork is needed for PPAP and works closely with customers to make the clearance process go more quickly.

Are you ready to find out how our experience with metal casting can help you make better wheels? Get in touch with us at hank.shen@fdbcasting.com to talk about your unique needs and find out why top automakers choose Fudebao Technology as their low pressure casting provider of choice.

References

Campbell, J. (2015). Complete Casting Handbook: Metal Casting Processes, Metallurgy, Techniques and Design. Butterworth-Heinemann.

Kaufman, J.G. and Rooy, E.L. (2004). Aluminum Alloy Castings: Properties, Processes, and Applications. ASM International.

Dispinar, D. and Campbell, J. (2011). Critical assessment of reduced pressure test. International Journal of Cast Metals Research, 24(5), 280-294.

Tiryakioğlu, M. (2020). Guidelines for Two-Parameter Weibull Analysis for Defect-Controlled Fatigue Life in Cast Aluminum Alloys. Metallurgical and Materials Transactions A, 51(5), 2091-2098.

Bonollo, F., Urban, J., Bonatto, B. and Botter, M. (2005). Gravity and low-pressure die casting of aluminium alloys: a technical and economical benchmark. La Metallurgia Italiana, 97(6), 23-32.

Lumley, R. (2018). Fundamentals of Aluminium Metallurgy: Recent Advances. Woodhead Publishing Series in Metals and Surface Engineering.

_1756348227989.webp)

_1756352561845.webp)

_1756360265131.webp)

_1756361323684.webp)