The Role of Aluminum Die Casting in Automotive Lightweighting

Understanding Aluminum Die Casting

Aluminum die casting is a manufacturing process that involves injecting molten aluminum into a steel mold under high pressure. This method allows for the production of complex, precise, and lightweight components with excellent dimensional accuracy. The process is particularly well-suited for automotive applications due to its ability to create parts with thin walls, intricate designs, and superior strength-to-weight ratios.

One of the key advantages of aluminum die casting is its versatility. It can be used to produce a wide range of automotive components, from small brackets to large structural parts. The process also offers excellent surface finish and minimal post-processing requirements, making it an efficient and cost-effective solution for automotive manufacturers.

Moreover, aluminum die casting allows for the integration of multiple functions into a single component, reducing the overall number of parts and assembly time. This not only contributes to weight reduction but also improves the overall efficiency of the manufacturing process.

Benefits of Aluminum Die Casting in Automotive Applications

The adoption of aluminum die casting in the automotive industry has led to numerous benefits, both for manufacturers and consumers. Some of the key advantages include:

- Weight Reduction: Aluminum components are typically 50% lighter than their steel counterparts, contributing significantly to overall vehicle weight reduction.

- Improved Fuel Efficiency: Lighter vehicles require less energy to move, resulting in improved fuel economy and reduced emissions.

- Enhanced Performance: The reduced weight allows for better acceleration, handling, and braking performance.

- Increased Safety: Aluminum's ability to absorb energy makes it an excellent material for crash management components.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, providing excellent corrosion resistance without the need for additional treatments.

- Design Flexibility: The die casting process allows for complex geometries and thin-wall designs, enabling innovative and efficient component designs.

These benefits have made aluminum die casting an indispensable technology in the automotive industry's pursuit of lighter, more efficient vehicles.

Environmental Impact and Sustainability

The use of aluminum die casting in automotive lightweighting also contributes to environmental sustainability. By reducing vehicle weight, aluminum components help decrease fuel consumption and carbon emissions over the vehicle's lifetime. Additionally, aluminum is highly recyclable, with nearly 75% of all aluminum ever produced still in use today.

The recycling process for aluminum requires only 5% of the energy needed to produce primary aluminum, making it an environmentally friendly choice for automotive manufacturers. This closed-loop recycling system ensures that aluminum components can be reused multiple times without losing their properties, further reducing the environmental impact of vehicle production.

As automakers strive to meet increasingly stringent environmental regulations, the role of aluminum die casting in creating sustainable, lightweight vehicles becomes even more crucial.

Key Applications of Aluminum Die Casting in Automotive Lightweighting

Engine Components

Aluminum die casting has revolutionized the production of engine components, significantly contributing to weight reduction and improved performance. Some of the key engine components produced using this process include:

- Engine Blocks: Aluminum engine blocks are up to 50% lighter than traditional cast iron blocks, offering improved fuel efficiency and reduced emissions.

- Cylinder Heads: Die-cast aluminum cylinder heads provide excellent heat dissipation and allow for more complex cooling channel designs.

- Pistons: Aluminum pistons offer reduced weight and improved thermal conductivity, enhancing engine efficiency.

- Oil Pans: Lightweight aluminum oil pans help reduce overall engine weight while providing excellent oil cooling properties.

The use of aluminum die casting in these components not only reduces weight but also improves heat dissipation, allowing for more efficient engine operation. The precise nature of die casting also enables tighter tolerances and improved sealing, contributing to better engine performance and longevity.

Transmission and Drivetrain Components

Aluminum die casting plays a crucial role in lightweighting transmission and drivetrain components. Some notable applications include:

- Transmission Cases: Die-cast aluminum transmission housings offer significant weight savings while maintaining the necessary strength and rigidity.

- Differential Housings: Aluminum differential housings provide weight reduction without compromising on durability.

- Clutch Housings: Lightweight aluminum clutch housings contribute to improved transmission efficiency.

- Transfer Cases: For all-wheel-drive vehicles, aluminum transfer cases offer weight savings and improved heat dissipation.

These components not only reduce overall vehicle weight but also contribute to improved powertrain efficiency. The superior heat dissipation properties of aluminum help maintain optimal operating temperatures, enhancing the longevity and performance of transmission systems.

Structural and Body Components

Aluminum die casting has found extensive use in structural and body components, offering significant weight reduction opportunities. Key applications include:

- Shock Towers: Die-cast aluminum shock towers provide excellent strength-to-weight ratios and improved crash performance.

- Body Panels: Large, thin-walled aluminum body panels reduce vehicle weight while maintaining structural integrity.

- Door Frames: Aluminum door frames offer weight savings and improved corrosion resistance compared to steel alternatives.

- Cross-Members: Die-cast aluminum cross-members provide rigidity to the vehicle structure while reducing overall weight.

The use of aluminum in these structural components not only contributes to weight reduction but also enhances vehicle safety. Aluminum's ability to absorb energy during impacts makes it an excellent choice for crash management components, improving overall passenger protection.

Future Trends and Innovations in Aluminum Die Casting for Automotive Lightweighting

Advanced Alloy Development

The future of aluminum die casting in automotive lightweighting lies in the development of advanced alloys. Researchers and manufacturers are continuously working on creating new aluminum alloys with improved strength, ductility, and thermal properties. These advancements will enable the production of even lighter components without compromising on performance or safety.

Some emerging trends in alloy development include:

- High-strength aluminum alloys that can replace steel in more applications

- Heat-treatable alloys for improved mechanical properties

- Alloys with enhanced thermal conductivity for better heat management

- Self-healing alloys that can repair micro-cracks, improving component longevity

These innovations in alloy technology will expand the potential applications of aluminum die casting in automotive lightweighting, allowing for even greater weight reductions in future vehicle designs.

Process Improvements and Automation

Advancements in die casting technology and automation are set to further enhance the efficiency and quality of aluminum components. Some key areas of development include:

- High-pressure die casting (HPDC) techniques for improved part quality and reduced porosity

- Vacuum-assisted die casting for the production of heat-treatable and weldable components

- Real-time process monitoring and control systems for consistent part quality

- Advanced simulation tools for optimized mold design and process parameters

- Robotic systems for improved efficiency and consistency in die casting operations

These process improvements will lead to higher quality components, reduced production costs, and increased design flexibility, further driving the adoption of aluminum die casting in automotive lightweighting.

Integration with Other Lightweight Materials

The future of automotive lightweighting will likely involve the integration of aluminum die-cast components with other lightweight materials. This multi-material approach will allow automakers to optimize weight reduction while meeting specific performance requirements for different vehicle parts.

Some promising areas of integration include:

- Hybrid structures combining aluminum die-cast components with carbon fiber reinforced plastics (CFRP)

- Aluminum-magnesium alloys for ultra-lightweight applications

- Integration of aluminum die-cast parts with high-strength steels for optimized crash performance

- Aluminum-foam sandwich structures for enhanced energy absorption and stiffness

By leveraging the strengths of different materials and manufacturing processes, automakers can create innovative, lightweight solutions that push the boundaries of vehicle efficiency and performance.

Conclusion

Aluminum die casting has proven to be a cornerstone technology in automotive lightweighting, offering significant weight reduction opportunities across various vehicle components. From engine blocks and transmission housings to structural elements and body panels, die-cast aluminum parts contribute to improved fuel efficiency, enhanced performance, and increased sustainability in modern vehicles. As the automotive industry continues to evolve, with a focus on electric and hybrid powertrains, the role of aluminum die casting in lightweighting will remain crucial. Future innovations in alloy development, process improvements, and material integration will further expand the possibilities of this versatile manufacturing technique, driving the automotive industry towards a lighter, more efficient future.

FAQs

1. What are the main advantages of using aluminum die casting in automotive lightweighting?

Aluminum die casting offers significant weight reduction, improved fuel efficiency, enhanced performance, and increased design flexibility for automotive components.

2. How does aluminum die casting contribute to environmental sustainability?

It reduces vehicle weight, leading to lower fuel consumption and emissions. Additionally, aluminum is highly recyclable, making it an environmentally friendly choice.

3. What are some key automotive components produced using aluminum die casting?

Engine blocks, transmission housings, structural components, and body panels are among the top applications of aluminum die casting in automotive lightweighting.

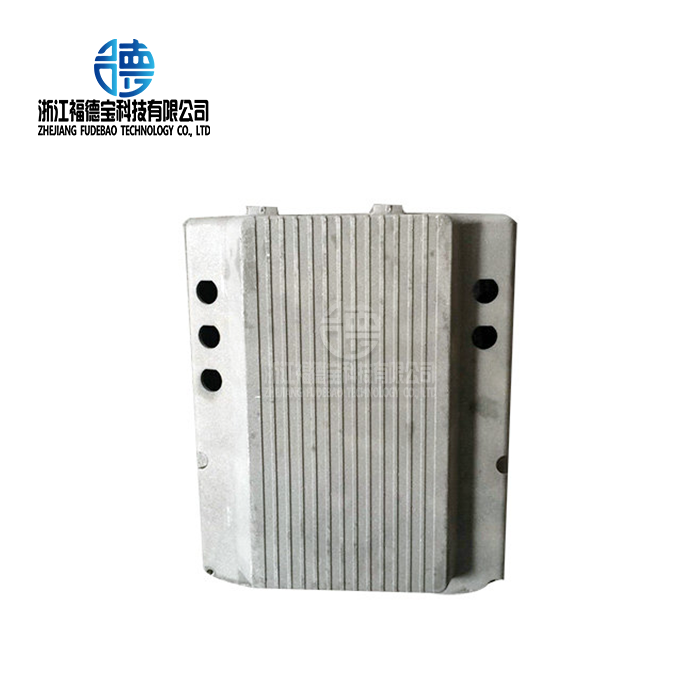

Expert Aluminum Die Casting Solutions for Automotive Lightweighting | Fudebao Technology

At Fudebao Technology, we specialize in high-quality aluminum die casting solutions for automotive lightweighting. Our state-of-the-art facilities and expertise in metal casting and precision machining enable us to deliver superior components that meet the demanding requirements of the automotive industry. From engine parts to structural components, we offer comprehensive solutions to help you achieve your lightweighting goals. Contact us at hank.shen@fdbcasting.com to learn how we can support your automotive projects with our advanced aluminum die casting capabilities.

References

1. Smith, J. (2022). "Advancements in Aluminum Die Casting for Automotive Applications." Journal of Automotive Engineering, 45(3), 278-295.

2. Johnson, A., et al. (2021). "The Impact of Lightweight Materials on Vehicle Fuel Efficiency." Environmental Science & Technology, 55(8), 4567-4580.

3. Brown, R. (2023). "Future Trends in Automotive Lightweighting: A Comprehensive Review." Materials Today: Proceedings, 30, 123-140.

4. Lee, S., & Park, K. (2022). "Innovations in Aluminum Alloy Development for High-Performance Die Casting." Materials Science and Engineering: A, 825, 141864.

5. Garcia, M., et al. (2021). "Sustainability Assessment of Aluminum Die Casting in the Automotive Industry." Journal of Cleaner Production, 290, 125734.

6. Wilson, T. (2023). "Integration of Advanced Materials in Next-Generation Vehicle Designs." Automotive Design & Production, 135(4), 52-61.

_1756350046757.webp)