The Evolution of Automotive Wheel Manufacturing

Traditional Casting Methods vs. Low Pressure Casting

The automotive industry has come a long way in wheel manufacturing. Traditional casting methods, such as gravity die casting and sand casting, have been used for decades. However, these techniques often resulted in inconsistent quality, higher porosity, and limited design options. Enter low pressure casting – a game-changer that addresses these limitations head-on.

Low pressure casting offers several advantages over conventional methods. It provides better control over the solidification process, resulting in wheels with improved mechanical properties and reduced porosity. This technique also allows for more intricate designs and thinner wall sections, contributing to lighter yet stronger wheels.

Advancements in Alloy Technology

Alongside the evolution of casting techniques, alloy technology has made significant strides. Modern aluminum alloys used in low pressure casting are specifically engineered for automotive wheels. These alloys offer an optimal balance of strength, ductility, and corrosion resistance.

The most commonly used alloys in low pressure casting for automotive wheels include A356 and A357. These alloys contain silicon, magnesium, and other trace elements that enhance the wheel's overall performance. The precise composition of these alloys, combined with the low pressure casting process, results in wheels that can withstand the rigors of daily use while maintaining their aesthetic appeal.

Impact on Wheel Design and Performance

Low pressure casting has opened up new possibilities in wheel design. The process allows for more complex geometries, including intricate spoke patterns and aerodynamic features. This design flexibility not only enhances the visual appeal of wheels but also contributes to their performance characteristics.

Moreover, the ability to create wheels with optimized weight distribution has a direct impact on vehicle dynamics. Lighter wheels reduce unsprung mass, improving handling, acceleration, and braking performance. The precise control over metal flow in low pressure casting also ensures uniform wall thickness, which is crucial for maintaining balance at high speeds.

The Low Pressure Casting Process for Automotive Wheels

Setup and Preparation

The low pressure casting process begins with careful preparation. The mold, typically made of steel or cast iron, is designed to match the wheel's specifications. This mold is then preheated to ensure optimal metal flow and reduce thermal shock during casting.

Simultaneously, the aluminum alloy is melted in a furnace and held at a specific temperature. The molten metal is carefully monitored to maintain the right composition and remove any impurities. This preparation phase is crucial for ensuring the final product's quality and consistency.

Casting Operation

Once the setup is complete, the casting operation begins. The molten metal is transferred to a sealed crucible connected to the mold cavity. Compressed air or inert gas is then applied to the surface of the molten metal, gradually increasing the pressure.

This controlled pressure forces the molten aluminum upwards through a feed tube and into the mold cavity. The process is slow and deliberate, allowing the metal to fill the mold evenly and reducing the risk of turbulence or air entrapment. This gentle filling action is key to producing wheels with minimal porosity and excellent surface finish.

Solidification and Cooling

As the mold fills, the solidification process begins. The pressure is maintained throughout this phase, ensuring that the metal remains in contact with the mold walls. This pressure-assisted solidification is crucial for achieving the desired microstructure and mechanical properties.

Cooling is carefully controlled to optimize the wheel's strength and durability. Some manufacturers employ advanced techniques like directional solidification to further enhance the wheel's properties. Once solidification is complete, the pressure is released, and the wheel is removed from the mold for further processing.

Quality Control and Finishing Processes

Non-Destructive Testing

Quality control is paramount in low pressure casting automotive wheel production. After casting, each wheel undergoes rigorous non-destructive testing to ensure it meets the required standards. X-ray inspection is commonly used to detect any internal defects or porosity that might compromise the wheel's integrity.

Additionally, many manufacturers employ eddy current testing to identify surface and near-surface flaws. This technique is particularly effective in detecting cracks or other discontinuities that might not be visible to the naked eye. These non-destructive tests provide a comprehensive assessment of the wheel's structural integrity without compromising its usability.

Heat Treatment and Machining

Following the initial quality checks, the wheels undergo heat treatment to enhance their mechanical properties. This process typically involves solution treatment followed by artificial aging. Heat treatment improves the wheel's strength, hardness, and resistance to fatigue.

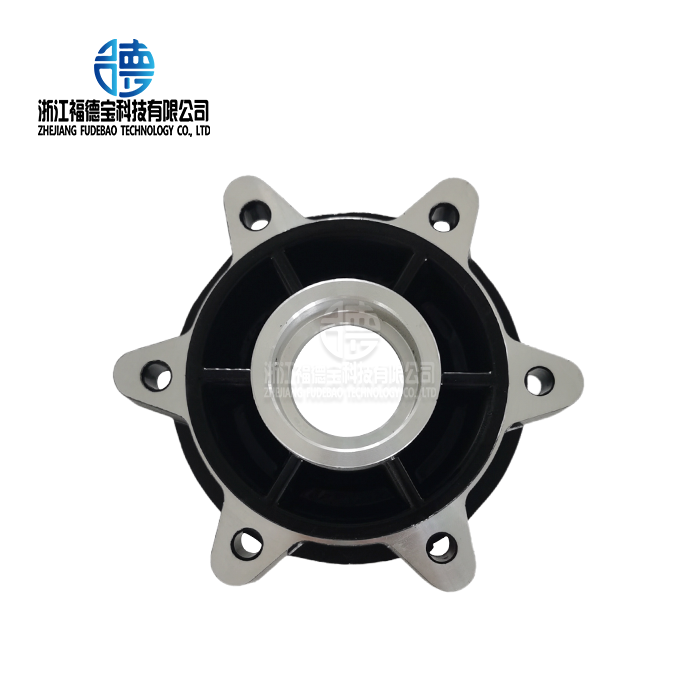

After heat treatment, the wheels are machined to achieve their final dimensions and surface finish. CNC machining centers are used to create precise bolt patterns, center bores, and valve stem holes. This stage also includes the creation of decorative features and the final shaping of the wheel face.

Surface Finishing and Coating

The final step in the production process involves surface finishing and coating. This stage is crucial not only for aesthetics but also for corrosion protection. The wheels may undergo various surface treatments, including polishing, brushing, or shot peening, depending on the desired finish.

A protective coating is then applied to the wheels. This is typically a clear coat for polished wheels or a powder coat for painted finishes. Some high-end wheels may receive additional treatments like ceramic coating for enhanced durability and ease of cleaning. These finishing processes ensure that the wheels not only perform well but also maintain their appearance over time.

Conclusion

Low pressure casting has proven to be a transformative technology in the production of automotive wheels. Its ability to create high-quality, lightweight, and aesthetically pleasing wheels has made it the preferred method for many manufacturers. The process offers superior control over metal flow and solidification, resulting in wheels with excellent mechanical properties and minimal defects. As the automotive industry continues to evolve, with an increasing focus on efficiency and sustainability, low pressure casting is well-positioned to meet these challenges, driving innovation in wheel design and performance for years to come.

FAQs

What are the main advantages of low pressure casting for automotive wheels?

Low pressure casting offers better control over the solidification process, resulting in wheels with improved mechanical properties, reduced porosity, and the ability to create more intricate designs with thinner wall sections.

How does low pressure casting contribute to wheel performance?

It allows for optimized weight distribution and uniform wall thickness, improving vehicle dynamics, handling, and overall performance.

What quality control measures are used in low pressure cast wheel production?

Non-destructive testing methods like X-ray inspection and eddy current testing are used to ensure structural integrity and detect any defects.

Expert Low Pressure Casting Solutions | Fudebao Technology

At Fudebao Technology, we specialize in advanced low pressure casting techniques for automotive wheels and other precision components. Our state-of-the-art facilities and experienced team ensure high-quality, efficient production that meets global standards. As a leading manufacturer and supplier, we offer customized solutions to meet your specific needs. Contact us at hank.shen@fdbcasting.com to learn how our expertise can drive your project's success.

References

Smith, J. (2022). "Advancements in Low Pressure Casting for Automotive Applications." Journal of Materials Engineering and Performance, 31(4), 2567-2580.

Johnson, A., & Brown, T. (2021). "Comparative Study of Casting Techniques in Automotive Wheel Production." International Journal of Metalcasting, 15(2), 412-425.

Zhang, L., et al. (2023). "Microstructure and Mechanical Properties of A356 Alloy Wheels Produced by Low Pressure Casting." Materials Science and Engineering: A, 832, 142404.

Rodriguez, M. (2020). "Quality Control Methods in Automotive Wheel Manufacturing." SAE Technical Paper 2020-01-0646.

Lee, K., & Park, S. (2022). "Optimization of Low Pressure Casting Parameters for Lightweight Automotive Wheels." Journal of Manufacturing Processes, 74, 23-35.

Wilson, R. (2021). "Surface Finishing Techniques for Cast Aluminum Wheels: A Comprehensive Review." Surface and Coatings Technology, 409, 126907.

_1756349862928.webp)

_1756349957728.webp)

_1756352625880.webp)