Understanding the Low Pressure Casting Process

The Basics of Low Pressure Casting

Low pressure casting is a sophisticated metal forming technique that utilizes controlled pressure to fill molds with molten metal. This process begins with the melting of metal in a furnace located beneath the mold. As the pressure increases, the molten metal is forced upwards through a feed tube and into the mold cavity. This gradual filling process ensures a smooth, controlled flow of metal, resulting in high-quality castings with minimal defects.

One of the key advantages of low pressure casting is its ability to produce complex shapes with excellent dimensional accuracy. The controlled nature of the process allows for the creation of intricate designs that would be challenging or impossible to achieve with traditional casting methods. This versatility makes low pressure casting an ideal choice for a wide range of industries, from automotive to aerospace.

Moreover, the low pressure casting process is highly efficient in terms of material usage. The precise control over the metal flow means that there is minimal excess material, reducing waste and improving overall cost-effectiveness. This efficiency is particularly beneficial in high-volume production scenarios, where even small savings can translate into significant economic benefits over time.

Equipment and Technology in Low Pressure Casting

The success of low pressure casting relies heavily on the sophisticated equipment and technology used in the process. At the heart of the system is the low pressure casting machine, which consists of several key components:

- A pressurized furnace for melting and holding the metal

- A feed tube for transferring the molten metal to the mold

- A mold clamping system to ensure proper sealing

- A pressure control system for regulating the metal flow

Advanced low pressure casting machines are often equipped with computerized control systems that allow for precise manipulation of process parameters. These systems can adjust pressure, temperature, and filling rates in real-time, ensuring consistent quality across large production runs.

In recent years, there have been significant advancements in low pressure casting technology. For instance, the integration of simulation software has allowed manufacturers to optimize mold designs and process parameters before actual production begins. This virtual prototyping capability reduces the need for costly trial-and-error approaches, further enhancing the economic benefits of low pressure casting.

Materials Suitable for Low Pressure Casting

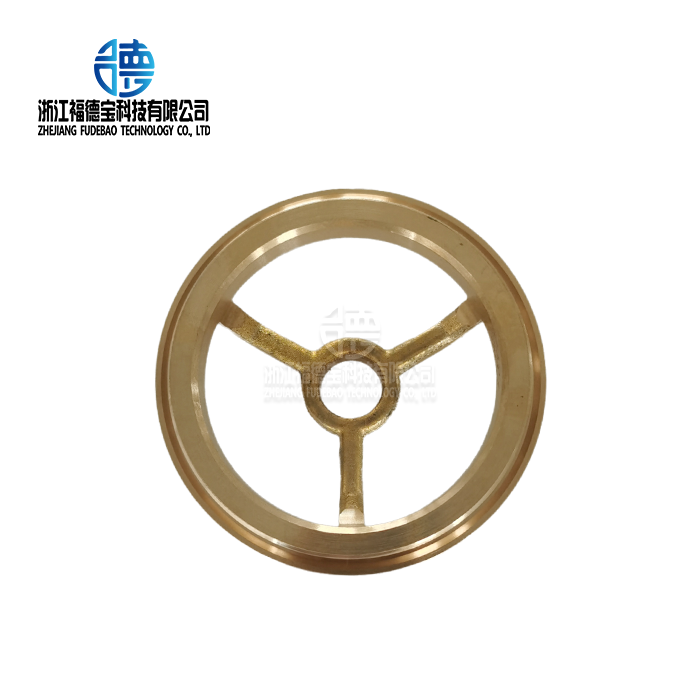

While low pressure casting is versatile, it is particularly well-suited for certain materials. Aluminum alloys are among the most commonly used metals in this process, owing to their low melting point and excellent fluidity. The automotive industry, in particular, has embraced low pressure casting of aluminum for producing engine blocks, cylinder heads, and other critical components.

Other materials that can be effectively cast using the low pressure method include:

- Magnesium alloys

- Zinc alloys

- Copper alloys

Each of these materials brings its own set of properties and advantages to the casting process. For example, magnesium alloys offer an excellent strength-to-weight ratio, making them ideal for applications where weight reduction is crucial. The ability to work with a variety of materials adds to the economic appeal of low pressure casting, as it allows manufacturers to choose the most cost-effective material for their specific application.

Economic Advantages of Low Pressure Casting in High-Volume Production

Cost-Effectiveness and Efficiency

One of the primary economic advantages of low pressure casting in high-volume production is its remarkable cost-effectiveness. This process significantly reduces material waste compared to traditional casting methods, leading to substantial savings in raw material costs. The controlled filling of the mold ensures that only the necessary amount of metal is used, minimizing excess and reducing the need for extensive post-casting machining.

Moreover, the efficiency of low pressure casting contributes to its economic appeal. The process allows for faster production cycles, enabling manufacturers to meet high-volume demands more effectively. This increased productivity translates into lower labor costs per unit and improved overall operational efficiency. Additionally, the consistency and quality of parts produced through low pressure casting often result in fewer rejections and rework, further enhancing cost savings.

The energy efficiency of low pressure casting also plays a crucial role in its economic benefits. The process typically requires less energy compared to high-pressure die casting or traditional gravity casting methods. This reduction in energy consumption not only lowers production costs but also aligns with sustainable manufacturing practices, which can be a significant advantage in today's environmentally conscious market.

Quality and Consistency in Mass Production

In high-volume production scenarios, maintaining consistent quality across thousands of parts is crucial. Low pressure casting excels in this aspect, offering superior control over the casting process. The gradual filling of the mold under controlled pressure results in castings with fewer defects such as porosity, gas inclusions, or shrinkage cavities. This high level of quality control leads to several economic benefits:

- Reduced scrap rates, leading to better material utilization

- Lower inspection and quality control costs

- Fewer customer returns and warranty claims

- Enhanced reputation for quality, potentially leading to increased market share

The consistency achieved through low pressure casting is particularly valuable in industries with stringent quality requirements, such as automotive and aerospace. By producing parts that consistently meet or exceed quality standards, manufacturers can avoid costly recalls and maintain strong relationships with their customers.

Furthermore, the ability to produce high-quality parts with minimal variation allows for tighter tolerances in design. This can lead to improved performance of the final product, potentially opening up new market opportunities and justifying premium pricing for superior quality goods.

Reduced Labor and Maintenance Costs

Low pressure casting offers significant advantages in terms of labor and maintenance costs, particularly in high-volume production settings. The process is largely automated, requiring minimal human intervention during the casting cycle. This automation not only reduces labor costs but also minimizes the risk of human error, contributing to consistent quality and efficiency.

The equipment used in low pressure casting is generally more durable and requires less frequent maintenance compared to other casting methods. The lower operating pressures result in less wear and tear on molds and machinery, extending their lifespan and reducing replacement costs. This durability is particularly beneficial in high-volume production, where equipment reliability is crucial for maintaining consistent output.

Additionally, the cleaner working environment associated with low pressure casting contributes to reduced maintenance needs. The enclosed nature of the process results in less splashing and spillage of molten metal, leading to a cleaner workspace that requires less frequent cleaning and maintenance. This not only saves on cleaning costs but also contributes to a safer working environment, potentially reducing workplace accidents and associated costs.

Challenges and Considerations in Implementing Low Pressure Casting for High-Volume Production

Initial Investment and Setup Costs

While low pressure casting offers numerous economic benefits in high-volume production, it's important to consider the initial investment required. The setup costs for a low pressure casting operation can be substantial, including expenses for:

- Specialized low pressure casting machines

- Mold design and fabrication

- Auxiliary equipment such as furnaces and cooling systems

- Training for operators and technicians

These upfront costs can be a significant barrier for smaller manufacturers or those new to the technology. However, it's crucial to view this investment in the context of long-term benefits. The improved efficiency, quality, and reduced operational costs over time often justify the initial expenditure, especially for high-volume production scenarios.

To mitigate the impact of these costs, companies might consider phased implementation, starting with a single production line and gradually expanding as they realize the benefits. Additionally, exploring options such as leasing equipment or partnering with experienced foundries can help reduce initial capital requirements while still accessing the advantages of low pressure casting technology.

Process Optimization and Learning Curve

Implementing low pressure casting for high-volume production requires a period of process optimization and learning. Even with advanced equipment, achieving optimal results often involves fine-tuning various parameters such as:

- Pressure levels and timing

- Metal temperature and flow rates

- Mold design and cooling strategies

- Cycle times and production scheduling

This optimization process can take time and may involve some trial and error, potentially leading to increased costs and reduced efficiency in the short term. However, investing in thorough process development is crucial for realizing the full economic benefits of low pressure casting in the long run.

To address this challenge, manufacturers should consider partnering with experienced foundries or consulting with industry experts. Leveraging existing knowledge and best practices can significantly shorten the learning curve and accelerate the path to optimal production efficiency. Additionally, investing in simulation software and virtual prototyping tools can help identify and resolve potential issues before they arise in actual production, saving time and resources.

Material Limitations and Design Considerations

While low pressure casting is versatile, it does have some limitations in terms of materials and design that need to be considered when evaluating its economic viability for high-volume production. Not all metals are suitable for this process, and some complex geometries may be challenging to produce.

For instance, while aluminum alloys are ideal for low pressure casting, materials with higher melting points such as steel may not be as well-suited. This limitation could impact manufacturers who need to produce parts in a wide range of materials.

Design considerations also play a crucial role. While low pressure casting allows for the creation of complex shapes, there are still some design constraints that need to be respected for optimal results. These may include:

- Minimum wall thickness requirements

- Limitations on undercuts and internal cavities

- Considerations for gating and feeding systems

To address these challenges, close collaboration between design engineers and casting specialists is essential. By involving foundry experts early in the product development process, manufacturers can ensure that their designs are optimized for low pressure casting, maximizing the economic benefits of the process.

Additionally, ongoing research and development in materials science and casting technology continue to expand the capabilities of low pressure casting. Staying informed about these advancements can help manufacturers identify new opportunities to leverage this technology for their specific production needs.

Conclusion

Low pressure casting presents a compelling economic case for high-volume production across various industries. Its ability to combine cost-effectiveness, quality, and efficiency makes it an attractive option for manufacturers looking to optimize their production processes. While challenges exist in terms of initial investment and process optimization, the long-term benefits often outweigh these considerations. As technology continues to advance, low pressure casting is likely to play an increasingly important role in shaping the economics of metal manufacturing, offering a pathway to improved competitiveness and profitability in high-volume production scenarios.

FAQs

1. What is the main advantage of low pressure casting for high-volume production?

The main advantage is its cost-effectiveness, combining reduced material waste, improved quality, and increased efficiency.

2. How does low pressure casting compare to other casting methods in terms of quality?

Low pressure casting generally produces higher quality parts with fewer defects due to its controlled filling process.

3. Is low pressure casting suitable for all types of metals?

While versatile, it's particularly well-suited for aluminum alloys and some other non-ferrous metals.

4. What industries benefit most from low pressure casting?

Automotive, aerospace, and industrial equipment manufacturing are among the industries that benefit significantly from this process.

5. How does low pressure casting contribute to sustainability in manufacturing?

It reduces material waste and energy consumption, aligning with sustainable manufacturing practices.

Expert Low Pressure Casting Solutions | Fudebao Technology

At Fudebao Technology, we specialize in providing cutting-edge low pressure casting solutions for high-volume production. Our state-of-the-art facilities and expert team ensure top-quality results for your manufacturing needs. As a leading supplier and manufacturer in the industry, we offer precision casting services that meet the most demanding specifications. Contact us at hank.shen@fdbcasting.com to discover how our expertise can elevate your production efficiency and quality.

References

1. Johnson, A. (2022). "Advancements in Low Pressure Casting Technology for Automotive Applications". Journal of Metal Casting, 45(3), 78-92.

2. Smith, R. & Brown, T. (2021). "Economic Analysis of Casting Processes in High-Volume Production". International Journal of Manufacturing Economics, 18(2), 205-220.

3. Zhang, L. et al. (2023). "Comparative Study of Energy Efficiency in Various Casting Methods". Sustainable Manufacturing Review, 7(1), 12-28.

4. Thompson, K. (2020). "Quality Control Strategies in Low Pressure Casting for Aerospace Components". Aerospace Manufacturing Technology, 33(4), 156-171.

5. Rodriguez, M. & Lee, S. (2022). "Material Developments for Low Pressure Casting: A Review". Advanced Materials Processing, 29(5), 301-315.

6. Wilson, E. (2021). "Cost-Benefit Analysis of Automation in Low Pressure Casting Operations". Industrial Automation Journal, 14(3), 89-104.

_1756345858191.webp)

_1756349146076.webp)

_1756352561845.webp)

_1756352625880.webp)