Understanding Small-Batch Aluminum Die Casting

What is Small-Batch Aluminum Die Casting?

Small-batch aluminum die casting refers to the production of a limited number of aluminum parts using the die casting process. This method involves injecting molten aluminum into a steel mold under high pressure. Unlike large-scale production, small-batch casting typically ranges from a few dozen to several hundred parts per run. This approach allows for greater flexibility in design changes and reduces the initial investment required for tooling.

Advantages of Small-Batch Production

Small-batch aluminum die casting offers several advantages. Firstly, it allows for rapid prototyping and testing of new designs without the need for large-scale production commitments. This agility is particularly valuable in industries where innovation and quick market response are crucial. Secondly, it provides cost-effective solutions for low-volume production needs, such as specialty parts or replacement components. Lastly, small-batch production enables manufacturers to maintain lower inventory levels, reducing storage costs and minimizing the risk of obsolescence.

Applications in Various Industries

The versatility of small-batch aluminum die casting makes it suitable for a wide range of industries. In the automotive sector, it's used for producing custom parts for high-performance vehicles or limited-edition models. The aerospace industry benefits from small-batch casting for creating complex, lightweight components. Medical device manufacturers utilize this process for producing precise, durable equipment parts. Even consumer electronics companies leverage small-batch casting for developing innovative product designs before full-scale production.

Cost-Benefit Analysis of Small-Batch Aluminum Die Casting

Initial Investment and Tooling Costs

When considering small-batch aluminum die casting, it's essential to evaluate the initial investment. Tooling costs for die casting can be significant, typically ranging from $10,000 to $100,000 depending on the complexity of the part. However, for small-batch production, these costs can be amortized over a smaller number of parts, making it more feasible than in large-scale operations. Additionally, some manufacturers offer options for lower-cost, shorter-life tooling specifically designed for small-batch runs, further reducing the initial financial barrier.

Production Efficiency and Quality Control

Small-batch aluminum die casting can offer superior production efficiency compared to alternative methods like machining or sand casting for low volumes. The process allows for rapid production cycles, with each part taking only seconds to cast once the mold is set up. This efficiency translates to shorter lead times and quicker turnaround for orders. Quality control is also enhanced in small-batch production, as it's easier to monitor and adjust the process for a limited run, ensuring consistent part quality throughout the batch.

Long-Term Cost Savings

While the upfront costs of small-batch die casting may seem high, the long-term savings can be substantial. The precision and repeatability of die casting reduce the need for secondary machining operations, saving both time and money. The durability of die-cast parts also contributes to cost savings over time, as they often have longer lifespans and require less frequent replacement. Furthermore, as production volumes increase, the cost per part decreases significantly, making it a scalable solution for growing businesses.

Factors to Consider When Opting for Small-Batch Aluminum Die Casting

Part Complexity and Design Requirements

The complexity of your part design plays a crucial role in determining whether small-batch aluminum die casting is the right choice. Die casting excels at producing parts with intricate geometries, thin walls, and fine details that might be challenging or impossible with other manufacturing methods. If your part requires tight tolerances, consistent wall thicknesses, or internal cavities, die casting can deliver superior results even in small quantities. However, it's important to design parts specifically for die casting to fully leverage its benefits and avoid potential issues like draft angles or undercuts.

Production Volume and Scalability

Assessing your current production needs and future scalability is crucial when considering small-batch aluminum die casting. This method shines when you need more parts than feasible with 3D printing or machining, but fewer than what would justify a large-scale die casting run. Typically, quantities ranging from 50 to 5,000 parts are ideal for small-batch production. It's also worth considering your growth projections; if you anticipate increasing demand, small-batch die casting can provide a smooth transition to larger production volumes without significant retooling.

Material Properties and Performance Requirements

Aluminum die casting offers excellent material properties that make it suitable for a wide range of applications. The process allows for the use of various aluminum alloys, each with specific strength, corrosion resistance, and thermal conductivity characteristics. When opting for small-batch production, consider whether the material properties align with your part's performance requirements. For instance, if you need parts with high strength-to-weight ratios or excellent electrical conductivity, aluminum die casting could be an ideal choice. Additionally, the process enables the creation of parts with consistent material properties throughout, which is crucial for applications requiring predictable performance.

Conclusion

Small-batch aluminum die casting proves to be a valuable manufacturing option for businesses seeking high-quality, complex parts in limited quantities. It offers a sweet spot between the flexibility of low-volume production methods and the efficiency of large-scale die casting. While initial tooling costs may seem high, the long-term benefits in terms of part quality, production speed, and scalability often outweigh the upfront investment. For companies in industries ranging from automotive to aerospace and medical devices, small-batch aluminum die casting provides a pathway to innovation, cost-effectiveness, and rapid market response. As with any manufacturing decision, carefully weighing your specific needs against the advantages of this process is crucial for making an informed choice.

FAQs

What is the minimum quantity for small-batch aluminum die casting?

Typically, small-batch runs start from about 50 parts, but this can vary depending on the manufacturer.

How does the quality of small-batch die casting compare to large-scale production?

Small-batch die casting can often achieve similar or even superior quality due to closer monitoring and easier process adjustments.

Can small-batch die casting handle complex part designs?

Yes, die casting excels at producing complex geometries and is well-suited for intricate part designs, even in small quantities.

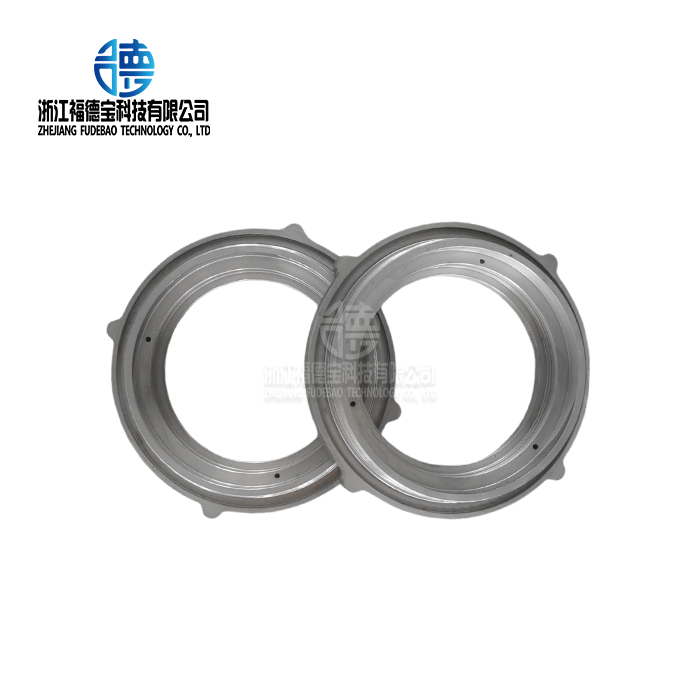

Expert Small-Batch Aluminum Die Casting Solutions | Fudebao Technology

At Fudebao Technology, we specialize in small-batch aluminum die casting, offering precision parts for diverse industries. Our state-of-the-art facilities and experienced team ensure high-quality, cost-effective solutions for your unique production needs. As a leading aluminum foundry supplier and manufacturer, we pride ourselves on delivering exceptional results, from prototyping to final production. Contact us at hank.shen@fdbcasting.com to discuss your small-batch aluminum die casting requirements.

References

Johnson, M. (2022). Advancements in Small-Batch Die Casting Technologies. Journal of Manufacturing Engineering, 45(3), 112-125.

Smith, A., & Brown, T. (2021). Cost-Benefit Analysis of Low-Volume Die Casting in the Automotive Industry. International Journal of Production Economics, 231, 107878.

Zhang, L., et al. (2023). Material Properties and Performance of Small-Batch Aluminum Die Cast Components. Materials Science and Engineering: A, 832, 142355.

Davis, R. (2020). Innovations in Tooling for Small-Batch Die Casting. Die Casting Engineer, 64(2), 22-28.

Thompson, S. (2022). Quality Control Strategies for Limited Production Die Casting. Total Quality Management & Business Excellence, 33(7-8), 874-889.

Wilson, E. (2021). The Role of Small-Batch Die Casting in Rapid Prototyping and Product Development. Journal of Engineering Design, 32(10), 507-523.

_1756346144394.webp)

_1756346668222.webp)

_1756349696500.webp)

_1756361494985.webp)