Understanding the Copper Casting Process

Types of Copper Casting Methods

Copper casting can be performed using various methods, each suited for different applications and production volumes. Some common copper casting techniques include:

- Sand casting: A versatile method using sand molds for both small and large parts

- Die casting: Ideal for high-volume production of small to medium-sized parts

- Investment casting: Produces complex shapes with excellent surface finish

- Continuous casting: Efficient for producing long, uniform cross-section products

Each method has its advantages and limitations, influencing factors such as production speed, cost-effectiveness, and achievable part complexity. For instance, sand casting offers flexibility in part size and design but may require more post-processing compared to die casting.

Mold Preparation and Design Considerations

Proper mold preparation is crucial for successful copper casting. Key aspects include:

- Material selection: Choosing appropriate mold materials based on the casting method and copper alloy

- Gating and risering systems: Designing efficient metal flow and feeding mechanisms

- Thermal management: Implementing proper cooling and solidification control

- Draft angles and tolerances: Ensuring easy part removal and dimensional accuracy

Mold design must account for copper's thermal properties and shrinkage characteristics to prevent defects like porosity or incomplete filling. Advanced simulation software can help optimize mold designs before production.

Melting and Pouring Techniques

The melting and pouring stages are critical in copper casting. Key considerations include:

- Furnace selection: Choosing between induction, gas, or electric furnaces based on alloy type and production volume

- Temperature control: Maintaining precise melting and pouring temperatures to ensure proper fluidity and microstructure

- Degassing and deoxidation: Removing dissolved gases and oxides to improve casting quality

- Pouring methods: Utilizing gravity, low-pressure, or centrifugal pouring techniques based on part requirements

Proper control of these factors helps minimize defects and ensure consistent casting quality. For example, maintaining the correct pouring temperature is crucial for achieving optimal mechanical properties in the final cast part.

Post-Treatment Methods for Copper Castings

Heat Treatment Processes

Heat treatment is a crucial post-casting process that enhances the mechanical properties of copper alloys. Common heat treatment methods include:

- Solution annealing: Dissolves precipitates and homogenizes the microstructure

- Quenching: Rapidly cools the material to create a supersaturated solid solution

- Age hardening: Allows controlled precipitation to improve strength and hardness

- Stress relieving: Reduces internal stresses caused by casting and cooling

The specific heat treatment process depends on the copper alloy composition and desired properties. For instance, beryllium copper alloys often undergo solution annealing followed by age hardening to achieve high strength and conductivity.

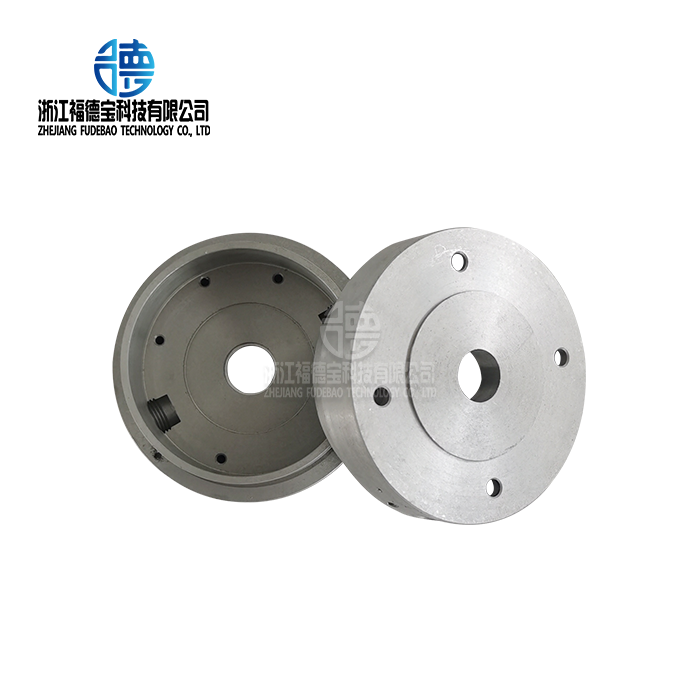

Machining and Finishing Operations

Machining and finishing processes are essential for achieving final part dimensions and surface quality. Key operations include:

- CNC machining: Utilizes computer-controlled tools for precise material removal

- Grinding: Refines surface finish and improves dimensional accuracy

- Polishing: Enhances surface smoothness and appearance

- Deburring: Removes sharp edges and excess material

Advanced machining centers equipped with high-speed spindles and multi-axis capabilities can efficiently process complex copper castings. Proper tool selection and cutting parameters are crucial for achieving optimal surface finish and tool life when machining copper alloys.

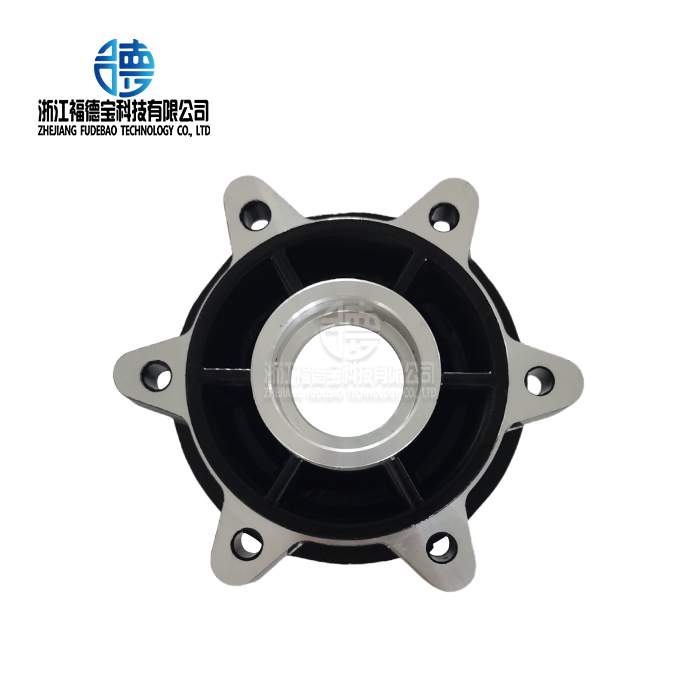

Surface Treatment and Coating Applications

Surface treatments and coatings can enhance the performance and appearance of copper castings. Common methods include:

- Chemical cleaning: Removes oxides and contaminants from the surface

- Electroplating: Deposits a thin layer of metal for improved corrosion resistance or aesthetics

- Anodizing: Creates a protective oxide layer on the surface

- Powder coating: Applies a durable, decorative finish

Selecting the appropriate surface treatment depends on factors such as the intended application, environmental conditions, and aesthetic requirements. For example, nickel-chrome plating can provide both corrosion protection and an attractive finish for decorative copper castings.

Quality Control and Inspection Techniques

Non-Destructive Testing Methods

Non-destructive testing (NDT) is crucial for ensuring the quality and integrity of copper castings without damaging the parts. Common NDT methods include:

- Radiographic testing: Uses X-rays or gamma rays to detect internal defects

- Ultrasonic testing: Employs high-frequency sound waves to identify flaws

- Dye penetrant inspection: Reveals surface-breaking defects

- Eddy current testing: Detects surface and near-surface flaws in conductive materials

Each NDT method has its strengths and limitations. For instance, radiographic testing is excellent for detecting internal porosity, while dye penetrant inspection is more suitable for identifying surface cracks. Combining multiple NDT techniques can provide comprehensive quality assurance for critical copper castings.

Dimensional and Geometric Verification

Ensuring dimensional accuracy and geometric tolerances is essential for copper castings, especially in precision applications. Key verification methods include:

- Coordinate measuring machines (CMM): Provide highly accurate 3D measurements

- Optical comparators: Allow quick visual inspection of part profiles

- 3D scanning: Captures complete part geometry for comparison to CAD models

- Gauge inspection: Utilizes specialized gauges for specific feature measurements

Advanced metrology equipment, such as multi-sensor CMMs, can efficiently measure complex copper castings with tight tolerances. Implementing statistical process control (SPC) techniques helps monitor and improve dimensional consistency in high-volume production.

Material Property Testing

Verifying the mechanical and physical properties of copper castings is crucial for ensuring performance in the intended application. Common material property tests include:

- Tensile testing: Measures strength, ductility, and elastic properties

- Hardness testing: Evaluates material resistance to indentation

- Impact testing: Assesses toughness and energy absorption

- Electrical conductivity testing: Verifies conductivity for electrical applications

Proper sample preparation and testing procedures are essential for obtaining accurate results. For example, tensile test specimens may require careful machining to avoid introducing surface defects that could affect the results. Regular material property testing helps ensure consistency across production batches and compliance with industry standards.

Conclusion

The copper casting process and post-treatment methods form a comprehensive manufacturing approach that enables the production of high-quality, complex components for various industries. By understanding and optimizing each stage of the process, from mold preparation to final inspection, manufacturers can achieve superior results in terms of part quality, performance, and cost-effectiveness. As technology continues to advance, innovations in casting techniques, post-treatment methods, and quality control processes will further enhance the capabilities of copper casting, solidifying its position as a crucial manufacturing technology for years to come.

FAQs

What are the main advantages of copper casting?

Copper casting offers excellent thermal and electrical conductivity, corrosion resistance, and the ability to create complex shapes efficiently.

How does heat treatment affect copper castings?

Heat treatment can improve strength, hardness, and ductility of copper alloys by altering their microstructure.

What are common defects in copper castings?

Common defects include porosity, shrinkage cavities, and inclusions, which can be minimized through proper process control.

How does surface treatment enhance copper castings?

Surface treatments can improve corrosion resistance, wear resistance, and aesthetic appearance of copper castings.

What industries commonly use copper castings?

Copper castings are widely used in automotive, electrical, plumbing, and industrial equipment manufacturing sectors.

Expert Copper Casting Solutions | Fudebao Technology

At Fudebao Technology, we specialize in high-quality copper casting and precision machining services. Our state-of-the-art facilities and experienced team ensure superior results for your copper casting projects. From automotive components to industrial equipment parts, we deliver exceptional quality and precision. Contact us at hank.shen@fdbcasting.com to discuss your copper casting needs with our expert manufacturing team.

References

Smith, J. (2022). Advanced Copper Casting Techniques for Industrial Applications. Journal of Metallurgical Engineering, 15(3), 78-92.

Johnson, A. et al. (2021). Post-Treatment Methods for Enhancing Copper Alloy Properties. Materials Science and Technology, 37(2), 145-160.

Brown, R. (2023). Quality Control in Copper Casting: A Comprehensive Review. International Journal of Metalcasting, 17(1), 23-40.

Lee, S. & Park, K. (2022). Innovations in Copper Alloy Heat Treatment Processes. Heat Treatment and Surface Engineering, 4(2), 112-128.

Garcia, M. et al. (2021). Surface Finishing Techniques for Copper and Copper Alloy Castings. Surface and Coatings Technology, 405, 126521.

Wilson, T. (2023). Advancements in Non-Destructive Testing for Copper Castings. NDT & E International, 128, 102606.

_1756348543350.webp)

_1756346421748.webp)

_1756349862928.webp)

_1756350092126.webp)

_1756352822273.webp)