When it comes to making things with complex shapes that are hard to do with other methods, sand casting is one of the most useful and cost-effective ways to make things. Using this method, which has been around for a long time, makers can make hard parts from aluminum, copper, and stainless steel that are very important for the automobile, industry, aircraft, and energy sectors. Even though sand casting is very versatile, getting the best results with complicated shapes isn't easy. It requires careful design and material choices, as well as very strict process control to reduce mistakes and maximize measurement accuracy.

Understanding the Challenges of Sand Casting Complex Geometries

When you are designing something, it is important to think about the special problems that can come up in casting work when dealing with complex shapes. When you're working with complex forms, mold distortion becomes a big problem because non-uniform temperature expansion can mess up the mold's accuracy. Incomplete filling happens a lot in places that are thin or hard for the metal to move into. This causes cold shuts and misruns that make parts useless.

Common Defects in Complex Casting Designs

Defects on the surface often happen because the mold isn't made ready in the right way or the closing systems are wrong. These problems get worse in complex shapes where metal has to find its way through complicated paths while keeping the temperature and flow speed steady. When something cools down and solidifies, thermal pressures can cause cracks on the inside, especially in areas where the walls are not evenly thick or where there are abrupt changes in shape.

Design for Manufacturability Principles

If you want to get a difficult sand casting job done right, design experts and foundry specialists need to work together from the start. The cast creation process can go more smoothly if you use design for manufacturability principles to spot possible issues ahead of time. It is easier to casting when you think about where to put parting lines, draft angles, and wall thickness changes.

Step-by-Step Design Tips for Better Sand Casting Outcomes

Systematic design improvement is the first step to getting better outcomes in complex shape casting. It is very important that the wall thickness be the same all the way through the part so that no hot spots form and the whole thing solidifies in the same way. Keeping changes in width within the right limits lowers the chance of fissures and high internal stress.

Essential Design Elements for Success

Draft angles are another important thing that affects both mold release and surface quality. A good amount of draft keeps the pattern cleaning process from getting moldy and also lowers the chances of surface flaws happening. The following design factors make casting results a lot better:

- Uniform wall thickness: Keeping the material spread even stops different cooling rates that can cause warpage and internal strains. To encourage smooth metal flow and controlled solidification patterns, changes in thickness should happen slowly instead of suddenly.

- Strategic fillet placement: Fillets and rounded corners get rid of sharp stress points and make it easier for metal to move. It is less likely that cracks will form with these design features, and the parts will last longer in working situations.

- Optimized gating systems: Proper gate design makes sure that the mold is completely filled while also avoiding turbulence and oxide formation. For complicated shapes, it might be necessary to use more than one gate to keep the metal moving at the right speed and temperature during the casting process.

These design rules help each other make shapes that are easy to cast and meet the useful needs of the project. If you use these tactics early on in the planning process, you can save a lot of time and money on development and production.

Material Selection and Mold Considerations

The quality of the surface finish and the accuracy of the dimensions are directly affected by the sand that is chosen. Green sand systems are very good at being reused and saving money, and chemically bound sands keep their shape better for complicated patterns. Depending on the needs of the product, mold chemicals can improve certain things like surface finish or collapsibility.

Comparing Sand Casting with Alternative Casting Methods for Complex Parts

In the complicated shape production space, several casting methods compete, each with its own pros and cons. Investment casting gives you a great surface finish and tight standards, but it takes a lot of time and money to do. Permanent mold casting has great accuracy but doesn't have the physical freedom that sand casting uses do.

Cost-Effectiveness Analysis

For medium to large parts, sand casting is still the best way to make them economically because other methods require too much money for the tools. The ability to quickly change designs without having to spend a lot of money on new tools makes this process especially useful when developing new products. The best way to make something depends on the amount produced, how complicated the part is, and the tolerance levels.

Process Selection Criteria

When choosing casting methods, procurement managers and engineers need to think about a lot of different things. The choice matrix is affected by part size limits, output number needs, measurement error standards, and surface finish standards. Sand casting is great for projects that need to be able to change easily, have a medium production volume, and find cheap ways to make things.

Maintenance and Process Optimization for High-Quality Complex Castings

Care for the equipment has a direct effect on both the quality of the casting and the regularity of the process. Regularly checking on pattern storage, casting tools, and sand handling systems keeps the quality from going down over time. Proper repair plans make sure that equipment runs well, keeps its physical accuracy, and extends its useful life.

Quality Control Implementation

Foundries can get the best results for each application by fine-tuning their processes based on data-driven feedback that supports ongoing growth. Keeping an eye on temperature, checking dimensions, and analyzing defects all give useful information for improving processes. Statistical process control methods help keep the quality level the same and find ways to make things better.

Sustainable Casting Practices

Today's casting processes focus on long-term environmental health through sand recovery programs and environmentally safe binding systems. These programs lower the impact on the earth without lowering the quality of the casting. Melting methods that use less energy and techniques for reducing waste both help with total operating efficiency and lowering costs.

Fudebao Technology: Your Partner for Advanced Sand Casting Solutions

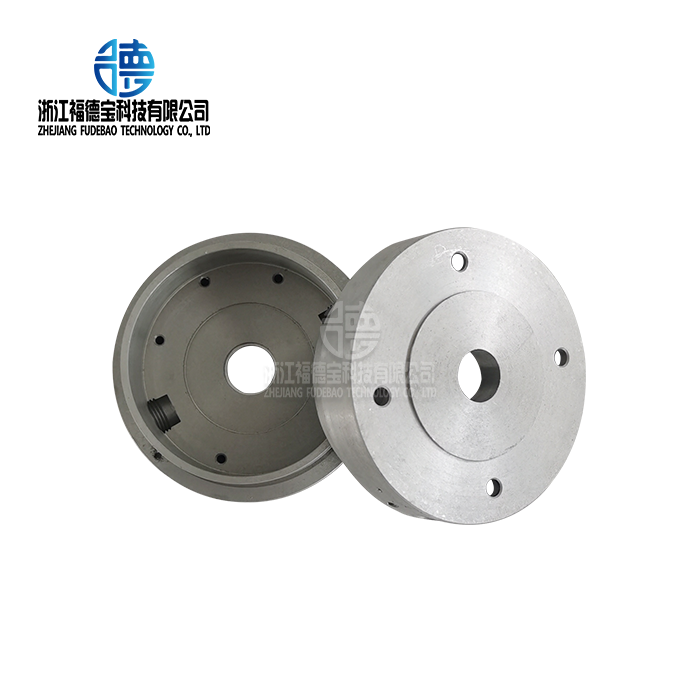

Zhejiang Fudebao Technology Co., Ltd. is a top producer that specializes in aluminum alloy, copper alloy, and stainless steel casting. Our wide-ranging manufacturing skills cover the whole production cycle, from melting to finishing and surface treatment. With our advanced CNC lathes, high-speed machining centers, low-pressure casting machines, and die casting tools, we can make precise parts with tolerances up to ±0.05mm.

Comprehensive Manufacturing Capabilities

Our unified method includes processes for melting, casting, precision cutting, and surface treatment all in one place. This all-in-one industrial environment maintains quality at every stage of production, lowers wait times, and makes it easier for people to talk to each other about their work. We serve customers around the world, including aerospace companies, car OEMs, makers of industrial equipment, and companies in the energy field who expect only the best quality and dependability.

Quality Assurance and Certifications

ISO licenses show our dedication to high quality. These international standards guide our work. Our quality control systems make sure that output standards are always the same and that we can trace the parts back to their source. This gives the aircraft and car industries the paperwork they need. Advanced inspection features help with complicated shape proof and strict tolerance needs.

Conclusion

To get the best results with sand casting on complicated shapes, you need to carefully think about the plan, the materials, and the way the process is set up. Engineers and procurement managers can make good choices that balance function and manufacturability when they understand the problems that come with complex shapes. Making changes to the plan in a strategic way, keeping the tools in good shape, and always looking for ways to do better all help make sure that casting goes well. Because it is flexible and inexpensive, sand casting is a good choice for making complicated parts for a wide range of industries. Foundry partners with a lot of experience who understand these ideas will help you get the best results while also lowering the risks and costs of development and production.

FAQs

For complicated shapes, what are the main benefits of sand casting?

Because it offers so much design freedom, sand casting lets makers make complex forms that other casting methods would make hard or impossible to do. The process makes medium-sized production runs with big parts affordable. You can easily make changes to sand models without having to spend a lot of money on new tools, which makes them great for developing prototypes and doing custom work.

How can changing the design help reduce casting flaws in parts that are hard to make?

Strategically changing the design helps a lot with a lot of common casting problems. Keeping the wall thickness even stops different rates of cooling, which leads to bending and internal pressures. Adding enough draft angles makes it easier for the mold to come off and prevents surface problems. Optimized gating and risering systems make sure that the cast is completely filled and the metal that is hardening flows correctly. This gets rid of a lack of density and shrinking flaws.

When it comes to making parts with a lot of small details, how does sand casting stack up against investment casting?

Investment casting has better surface quality and tighter measurement standards, but it needs more money and time up front. For most uses, sand casting has better size range, lower prices for tools, and enough accuracy. The choice relies on the price, the size of the parts, the amount that needs to be made, and how strict the tolerance rules are. When investment casting gets too expensive for bigger parts, sand casting is a great alternative.

Partner with Fudebao Technology for Your Sand Casting Needs

Fudebao Technology is ready to take your difficult math problems and turn them into successes in manufacturing. We have over 30 years of experience with precision metal cutting and casting, and we use the latest tools and world-class quality systems. This makes us the ideal sand casting provider for your business. We know the special needs of the automobile, aircraft, industrial equipment, and energy sectors. We give parts that meet the most difficult standards. Our wide range of skills, which includes everything from making quick prototypes to producing lots of copies, means that projects run smoothly no matter how difficult they are or how little time there is to complete them. Enjoy the benefits of working with a reliable sand casting producer who focuses on quality, new ideas, and making customers happy. To talk about your exact needs and see how our knowledge can help your next project, email us at hank.shen@fdbcasting.com.

References

Campbell, John. "Complete Casting Handbook: Metal Casting Processes, Metallurgy, Techniques and Design." Second Edition, Butterworth-Heinemann, 2015.

Beeley, Peter R. "Foundry Technology." Second Edition, Newnes, 2001.

American Foundry Society. "Sand Casting Manual." Sixth Edition, American Foundry Society, 2018.

Stefanescu, Doru Michael. "Science and Engineering of Casting Solidification." Third Edition, Springer, 2015.

Brown, John R. "Foseco Foundryman's Handbook: Facts, Figures and Formulae." Eleventh Edition, Butterworth-Heinemann, 2000.

Davis, Joseph R. "ASM Specialty Handbook: Cast Irons." ASM International, 1996.

_1756345858191.webp)

_1756346613780.webp)

_1756348300182.webp)