Rapid prototyping changes product development in a big way by making very fast and accurate physical models of mental ideas. At the very front of this change is CNC machining, which gives engineers and artists the amazing ability to make working models that are just like the real thing. Today's industry needs advanced modeling tools that can work with complicated shapes and keep high levels of accuracy. The use of computer numerical control technology in rapid prototyping has changed the way businesses do early-stage product development across industries from cars to aircraft. This has made it possible for, and faster iteration cycles and more informed design decisions.

Understanding CNC Machining in Rapid Prototyping

As a key part of modern industry, computer numerical control technology uses exact digital directions to move cutting tools through complicated machine processes. This automatic method guarantees uniform outcomes and gets rid of the mistakes that come up in hand production.

What is CNC Machining and How Does It Work?

Computer-controlled machining, or CNC machining, is a complex process that uses computer software, precise machines, and cutting tools to turn raw materials into finished parts. The first step in the process is to make detailed CAD models. Engineers use special software to turn these models into code that machines can read. This code has very specific directions for feed rates, cutting speeds, and tool routes.

The best thing about numerical control systems is that they can make sure that many different parts are always the same. CNC systems do the same thing over and over with very little change, unlike cutting methods done by hand that rely on the skill and knowledge of the person doing it. These days' CNC machines can reach standards as tight as ±0.001 inches. This makes them perfect for making working samples that are just like the real thing.

Multi-axis machining centers improve cutting by allowing movement along multiple lines at the same time. This makes it possible to create complicated shapes that couldn't be made at all or would take a very long time to make with more traditional methods. This ability to be used in many ways is especially helpful when designers are working on test versions of prototypes and need to test complex parts and features.

Materials Commonly Used for CNC Rapid Prototyping

The choice of materials has a big effect on both how well the prototype works and how true the tests are. CNC machining can be used on a lot of different materials. This gives designers the freedom to make sure that the qualities of a sample are very similar to the materials that will be used in production.

Aluminum metals are the most popular materials for prototypes because they are easy to machine, don't rust, and are very light. 6061-T6 and other similar grades offer great strength-to-weight ratios and keep good physical stability while being machined. When samples have to be in tough environments, versions made of stainless steel are better because they are more durable and resistant to chemicals.

For uses that need certain temperature or chemical qualities, engineering plastics make more materials available. ABS plastic has great impact strength and keeps its shape well, and PEEK plastic can handle very high temperatures for high-performance uses. Nylon types provide better protection to wear and flexibility for mechanical parts.

Specialty materials like titanium metals and advanced composites make it possible to prototype for high-performance uses in the aircraft and medical device industries. These materials need special cutting methods, but they have qualities that are very close to what the company needs.

Key Benefits of Using CNC Machining for Early-Stage Product Design

The benefits of using CNC technology in quick development go beyond just making it faster. These benefits lead to more accurate results, shorter development times, and better prototypes, all of which have a direct effect on the success of the end product.

High Precision and Tight Tolerances for Functional Prototypes

CNC machining is different from other prototype methods because it can do precision production. These days, machine tools often reach standards of ±0.05mm. This makes it possible to make samples that work just like the real parts. This level of precision is very important when checking mechanical systems, interference fits, and moving parts.

Engineers can try design factors separately when Repeatability makes sure that each sample version has the same size. Statistical process control methods keep an eye on machine accuracy all the time, which gives you faith in the correctness of the sample during all stages of the project.

Fast Turnaround and Scalability for Iterative Design

When you look at the timelines for CNC prototyping and older ways of making things, it's clear that CNC prototyping is faster. It usually takes just days for complicated systems to go from finalized design to finished prototype, and simple parts can be machined in just hours. This quick turnaround allows design testing processes to speed up, which shortens the overall development timeline.

Scalability makes it easy to go from one sample to a small production run without having to make big changes to the process. With software updates, changes to the design can be made right away. This avoids the long wait for tools that are common in other ways of making things. Batch freedom allows the number of prototypes to be changed depending on the needs of the testing and development stages.

Superior Surface Finishing and Post-Processing Options

The quality of the surface has a direct effect on how well prototypes can be tested and evaluated. CNC machining provides better surface finishes than additive manufacturing methods. This often means that extra processing isn't needed. Advanced cutting methods reduce lines from tools on surfaces and make sure that designs are ideal for certain uses.

Post-processing tools make prototypes work better and look nicer. Anodizing makes metal parts more colorful and protects them from rust. When needed, precision grinding can make surfaces that look like mirrors. For specific testing needs, chemical processes change the way the surface acts.

CNC Machining vs. Alternative Rapid Prototyping Methods

Choosing the right development methods depends on the needs, time limits, and performance goals of the project. Each technology has its own benefits that depend on the details of the application and the goals of the project.

CNC Machining vs. 3D Printing for Prototyping

Additive manufacturing is great at making complicated shapes on the inside of objects and quickly bringing ideas to life. But when practical testing is most important, CNC machining gives better mechanical traits and surface quality. In 3D printing, problems with layer bonding can make the prototypes weaker, but CNC machining keeps the material qualities the same as production parts.

It is important to keep in mind that the cost depends on how complicated the parts are and how many there need to be. For early idea development, simple shapes are okay with 3D printing. But for working samples that need to be exact and last a long time, CNC machining is better. With subtractive manufacturing, a wide range of materials can be used, making it possible to try prototypes with materials that are similar to those used in production.

CNC Machining vs. Injection Molding and Laser Cutting

Injection casting needs a lot of money to be spent on tools at the beginning, which makes it too expensive for sample amounts. CNC machining gets rid of the tools that are normally needed for prototype development while keeping the same level of physical accuracy. The setup time goes from weeks to hours, which lets you quickly change and test designs.

The material can't be too thick, and the shapes that can be made are limited, when using laser cutting. CNC machining can handle three-dimensional features and thick parts while keeping the accuracy of complicated shapes. Laser cutting can change the properties of the material in the "heat-affected zone," but CNC machining keeps those qualities intact.

Selecting the Right CNC Machining Service for Your Prototyping Needs

The partners you choose affect a lot, including the quality of your prototypes, how long it takes to develop, and the overall success of the project. When choosing a provider, it's important to look at their professional skills, quality control, and ability to be flexible with their services in order to make sure the best decisions are made.

Key Criteria for Choosing a CNC Machining Partner

The technical aspects of a person or company include the complexity of their tools, their machining ability, and their knowledge of different materials. Modern machine centers with multiple directions and advanced cutting systems make it possible to make complicated prototypes with great accuracy. The way you handle materials should fit with the needs of the project, including unique metals and advanced composites when they are needed.

Quality control methods show that suppliers are committed to making things with perfect accuracy. ISO 9001 certification shows that you follow good ways to handle quality, and AS9100 certification shows that you follow the rules in the aircraft business. Coordinate measure machines, surface profilometers, and other inspection tools make sure that parts are the right size and have the right surface quality.

The ability to customize services makes sure that project needs and time limits are taken into account. Responsive communication routes make it easier for everyone to work together on design and problem-solving during all stages of development. For jobs that need to be done quickly, delivery times can be affected by how close the packages are to their destination or by well-known ways of getting goods from one place to another.

Cost Considerations and How to Request CNC Machining Quotes Online

Because prototypes are made in smaller amounts, prototype cutting has different pricing models than regular manufacturing. Understanding what makes costs go up and down helps you prepare for projects and compare suppliers more accurately. The main cost factors are the material prices, how hard it is to machine, and how it needs to be finished.

Quote requests that work include thorough models, information about the materials, the number of items needed, and due dates. Clear conversation about surface finish standards and accuracy needs makes sure that there are no mistakes, and that the price is right. Supplier evaluations from multiple sources let you see which companies are better and helps you build relationships with suppliers for future projects.

Case Studies: Successful Early-Stage Product Designs Using CNC Machining

Real-world examples show that precision cutting has a huge effect on the results of product development. These examples show measurable benefits in a range of businesses and show the best ways to put these ideas into practice.

Examples of Rapid Prototyping Impact on Product Development Cycles

Automotive component development uses CNC machining to make metal samples that are light and allow for full testing before investing in production tools. Engine fixing parts need to be exactly right and able to fight shaking, which is what CNC samples can help with. Testing finds mistakes in design assumptions and also finds ways to make things lighter and better at performing.

Aerospace uses need the kind of constant accuracy and material tracking that CNC machining provides. Structural parts are put through very tough tests that require prototypes to be as accurate as the parts that are actually made. Titanium models help with wear analysis and stress tests that show what the final design and approval needs are.

Biocompatible materials and accurate features that are needed for regulatory compliance are good for medical device samples. CNC machining is a quick way to make working samples that can confirm the ergonomics of surgical tools. The quality of the surface finish makes it possible to do actual tests of how easy it is to use while still being able to process it in a clean way.

The measured benefits include shorter development cycles, which are usually 30% to 40% less than standard ways of making prototypes. Cost savings come from not having to go through design changes again and lowering the risk in production by making sure the sample works in every way. Better testing and design adjustments lead to better performance.

Conclusion

As a fundamental technology in modern fast development, CNC machining offers unmatched accuracy, the ability to work with a wide range of materials, and the option to produce small or large quantities of parts. The benefits go beyond just being able to make things. They also help with design feedback, speed up development processes, and get better product results. Businesses that use these tools can get products to market faster and with better quality, which gives them an edge over their competitors. Investing in precision testing technologies helps you avoid risks in the development process and come up with new ideas.

FAQs

How fast can I get a CNC made prototype?

It usually takes between 3 and 7 days to make a part, based on how complicated it is, what materials are used, and how it needs to be finished. Aluminum parts that are not complicated are usually done in 24 to 48 hours. More complicated systems that need more than one setting may need more time to make sure they are good quality.

Which materials should I use for CNC fast prototyping?

Aluminum alloys, stainless steel, and industrial plastics like ABS and nylon are the most popular options because they are easy to work with and can be used in many different ways. To make sure that prototype testing is true, the material that is used should be the same as or similar to the planned production materials.

During testing, can CNC machining handle changes to the design?

Yes, CNC machining is very good at making design changes through software updates, so new tools aren't needed. This flexibility helps with iterative development methods with little effect on cost or plan compared to methods that depend on specific tools.

Partner with Fudebao Technology for Your CNC Machining Needs

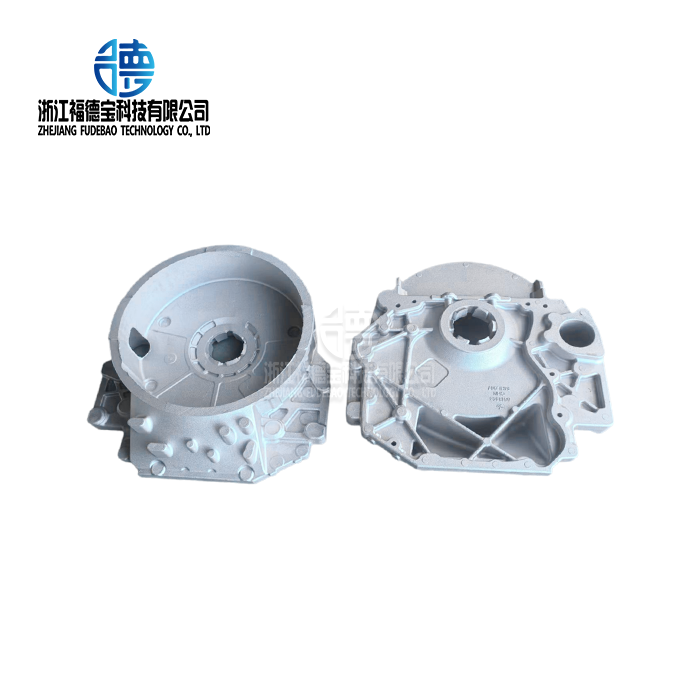

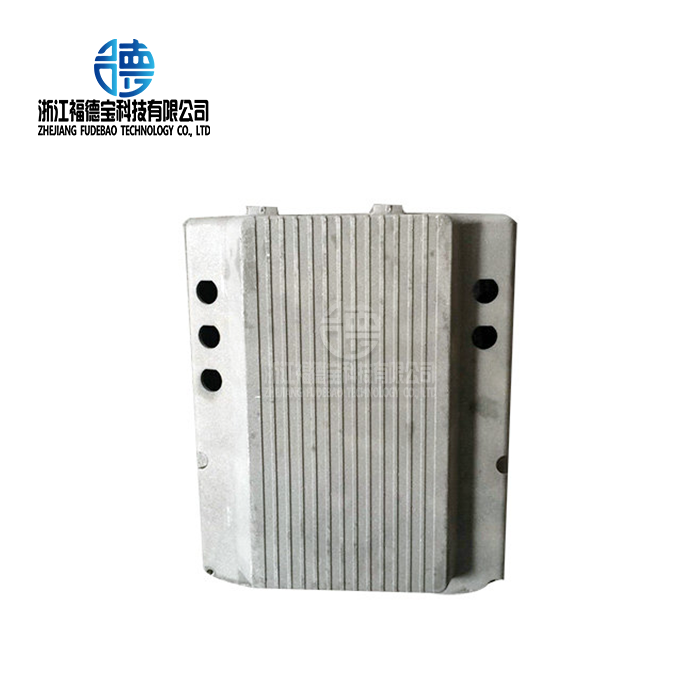

Zhejiang Fudebao Technology is ready to speed up the development of your products with accurate CNC machining and full prototyping services. Our brand new building has high-speed cutting centers and CNC lathes that are very accurate, with tolerances of up to ±0.05mm. We are a trusted CNC machining maker for the automobile, aircraft, and industrial equipment sectors around the world, and we offer full solutions from the beginning of the process to the delivery of the finished sample.

Our combined skills cover the whole production process, from low-pressure casting, die casting, and precise cutting to advanced surface processes. This all-encompassing method guarantees steady excellence while speeding up the delivery dates and planning of projects. While keeping important performance needs in mind, our technical team works closely with your experts to get the best designs for manufacturability.

Are you ready to turn your creative ideas into exact models? To talk about your exact needs and get full quotes for the project, please email us at hank.shen@fdbcasting.com.

References

Thompson, R.M. "Advanced CNC Machining Techniques for Rapid Prototyping Applications." Journal of Manufacturing Science and Engineering, Vol. 145, No. 3, 2023.

Chen, L., Martinez, A., and Williams, K. "Comparative Analysis of Rapid Prototyping Methods: CNC Machining vs. Additive Manufacturing." International Journal of Production Research, Vol. 61, No. 8, 2023.

Anderson, P.J. "Material Selection Strategies for CNC Rapid Prototyping in Automotive Applications." SAE International Journal of Materials and Manufacturing, Vol. 16, No. 2, 2023.

Kumar, S. and Johnson, M. "Cost-Benefit Analysis of CNC Machining for Early-Stage Product Development." Manufacturing Engineering Review, Vol. 89, No. 4, 2022.

Roberts, D.A., Smith, T.L., and Brown, J.R. "Precision Tolerance Achievement in CNC Prototype Manufacturing." Precision Engineering Journal, Vol. 78, 2022.

Liu, X., Davis, N., and Wilson, E. "Digital Manufacturing Integration: From CAD to CNC Prototype Production." Computer-Aided Design and Applications, Vol. 20, No. 5, 2023.

_1756348227989.webp)

_1756348356531.webp)