Multi-axis CNC machining allows complicated parts to be made in a whole new way. It lets the machine move across several directions at the same time, which greatly cuts down on setup time and improves the accuracy of the dimensions. Manufacturers can use this advanced technology to make complicated shapes with undercuts, deep holes, and tricky outlines all in one step. This gets rid of the need for multiple attachment changes that are common in standard 3-axis systems. Multi-axis machining can make very precise parts with complex shapes. This helps businesses that need these kinds of parts to meet their growing needs.

Limitations of Traditional CNC Machining in Complex Part Manufacturing

When making parts with a lot of details, traditional 3-axis machining tools run into a lot of problems. Because the tool can only move along the X, Y, and Z directions, it is hard to reach some of the more complex areas of the parts. This means that during production cycles, workers have to move the pieces they are working on around a lot.

Setup Complexity and Time Consumption

In traditional cutting, different surfaces on the part have to be reached by making a lot of changes to the clamp and moving the body around. Every time you change the setup, you could get measurement drift and alignment mistakes, which will hurt the quality of the end part. When manufacturing engineers make parts with complicated shapes, they often have a hard time with these issues. This is because each step of moving the part to a new place takes a lot of time and makes mistakes more likely.

Quality Consistency Challenges

Multiple setups naturally lead to changes in surface finish and tolerance stack-up across various finished surfaces. The hand moving process adds uncertainty that affects the accuracy of the dimensions and the uniformity of the surface. It is especially hard to deal with these quality issues in the aircraft and automobile businesses, where exact measurements cannot be changed.

Introduction to Multi-Axis CNC Machining and Its Capabilities

Multi-axis CNC machining technology adds more moving axes, usually the A- and C-axes. This goes beyond the old three-axis limits and allows for five-axis movement at the same time. With this improvement, cutting tools can get to workpieces from almost any angle without having to be moved.

Advanced Controller Technology

Today's multi-axis systems come with advanced CNC processors that can handle complicated G-code and toolpaths made by CAM. These controls allow for simultaneous moving on all directions while still keeping the position exactly right. Using advanced software methods makes it easier to interpolate between multiple directions. This leads to better surface finishes and measurement accuracy.

Rotary Table Integration

Multi-axis cutting relies on high-precision rotating tables. These parts make the circular movement possible to get to the complicated shapes of the parts. Because of the mix of linear and rotational movement, makers can machine complex features that would be impossible with conventional methods. This is because the tool can be positioned in ways that have never been done before.

How Multi-Axis CNC Machining Solves Complex Manufacturing Challenges?

Using multi-axis technology directly solves the most important problems in the making of complex multi-part objects. By allowing five-axis movement to happen all the time, makers can make complex shapes and keep great measurement accuracy.

Enhanced Geometric Flexibility

Multi-axis CNC machining systems are great at making the kinds of deep cuts and complicated shapes that are hard for older cutting methods. If you can keep the best cutting angles during the grinding process, you can get better surface finishes and don't need to do any extra steps. In aircraft uses, which often need light parts with complex internal passageways, this geometry freedom is very useful.

Reduced Setup and Cycle Times

Single-setup cutting skills cut production times greatly by not having to change fixtures or move workpieces. Multi-axis cutting can cut setup times by as much as 75% compared to older ways, according to manufacturing data. The ability to cut continuously also makes the tool last longer by keeping the best cutting conditions during the grinding cycle.

Improved Dimensional Accuracy

Removing different sets gets rid of things that can cause tolerance stack-up and placement mistakes. Multi-axis machining keeps the reference datums of the item in mind during all steps of the production process. This leads to better measurement accuracy and better feature-to-feature relationships. This level of precision lets makers reliably hit limits of ±0.001 inches even when the parts have complicated shapes.

Practical Design Tips and Material Considerations for Multi-Axis CNC Machining

When doing multi-axis cutting, the form and the material must be carefully thought about. Engineers need to find a balance between physical complexity and manufacturability in order to get the best results.

Design Optimization Strategies

When you create a part for multi-axis machining, you need to think about where to put features and how to make sure that they can be easily reached. Engineers should make as few thin-wall parts as possible that could bend when cutting forces are applied. They should also make sure that there is enough space for the cutting tools to move around. Adding the right draft angles and staying away from sharp interior corners makes it easier to machine parts and makes tools last longer.

Material Selection and Machining Parameters

Different materials need to be cut in certain ways to get the most out of multi-axis machining. If you use the right cutting settings, aluminum metals can be machined quickly. But titanium and stainless steel need careful tool selection and heat control. Being able to keep the best cutting angles over complex toolpaths makes it easy to machine tough materials that would be hard to work with if you used the normal ways.

Future Trends and Advantages for Procurement Managers and OEMs

As multi-axis cutting technology evolves, it keeps opening up new ways to make manufacturing more efficient and cheaper. New trends in technology and process improvement will give even more benefits to buying teams that think ahead.

AI Integration and Adaptive Machining

The addition of AI makes it possible to constantly fine-tune the settings for cutting based on how the material reacts and how the state of the tool is monitored. These smart systems instantly change the feeds and speeds to keep the best cutting conditions. This lowers the amount of wasted material and raises the tool's lifetime. Machine learning looks at machine data to figure out when to do upkeep and how to make the most of output plans.

Scalable Production Solutions

Multi-axis systems today can be scaled up or down in ways that weren't possible before. They can be used for both concept creation and high-volume production. The ability to quickly change between different part designs without a lot of setup changes gives procurement managers flexible manufacturing capabilities. This ability to change is especially useful in fields where demand and product types change often.

Conclusion

Multi-axis CNC machining is a revolutionary new way to make complicated parts. It offers amazing geometric freedom and measurement accuracy. The technology is very important for fields that need complex parts with exact specifications because it can avoid multiple sets while keeping the best surface quality. Manufacturing needs are changing to require more complexity and accuracy. Multi-axis machining has the power to meet these needs in a quick and cost-effective way.

FAQs

Which kinds of parts get the most benefit from multi-axis CNC machining?

Multi-axis cutting works best for complex parts with undercuts, deep holes, and tight spec that needs to be met. Aerospace, automobile, and medical device making are some of the industries that use this technology a lot to make complex shapes that would be too hard or too expensive to make with older machine techniques.

When dealing with complex parts, how does multi-axis CNC machining stack up against 3D printing?

3D printing is great for making quick prototypes and complex internal structures, but multi-axis cutting is better for useful parts when it comes to surface finish, material qualities, and physical accuracy. Multi-axis cutting also lets you work with more industrial materials and can get tighter limits that are needed for precise work.

Can multi-axis CNC machining reduce lead times for bulk orders?

Yes, multi-axis machining greatly shortens lead times by reducing changes in setup and allowing full part cutting in single processes. Removing multiple steps and parts improves the stability of quality across production runs and speeds up the production schedule.

Fudebao Technology: Your Multi-Axis CNC Machining Partner

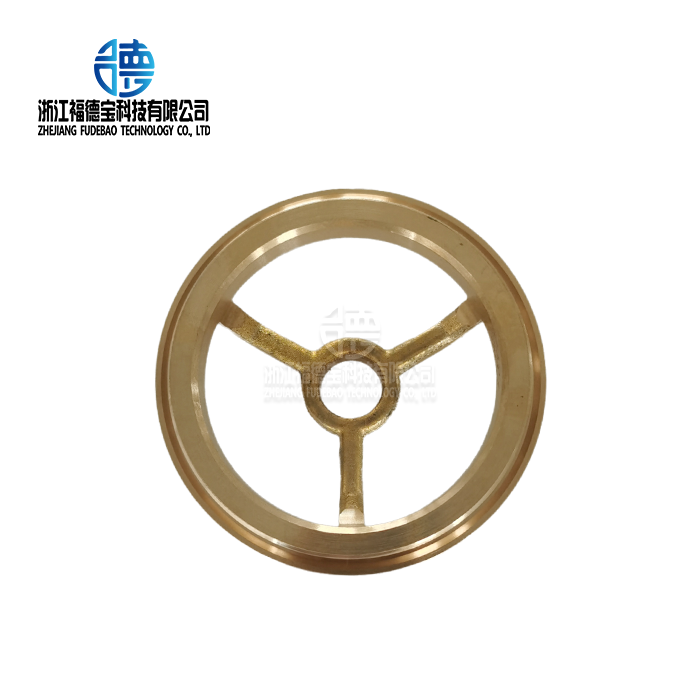

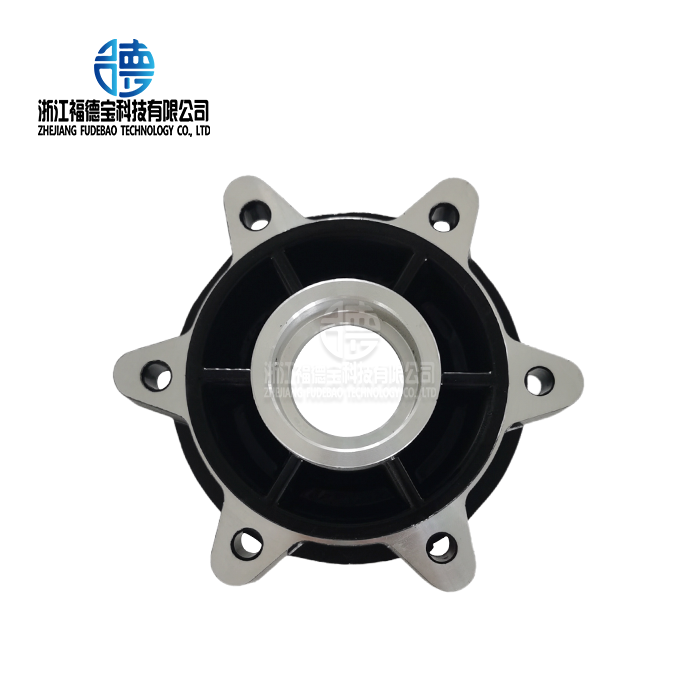

Zhejiang Fudebao Technology Co., Ltd. is a model business in precision cutting and metal casting. They focus on making parts out of stainless steel, copper alloy, and aluminum alloy for cars, industrial equipment, and airplanes around the world. Our cutting-edge facility combines high-speed machine centers, CNC lathes, and multi-axis systems with CNC lathes to provide a full range of industrial services.

With our multi-axis CNC machining, we can make complicated parts with an accuracy of ±0.05mm, which meets the strict standards for precise parts in the car industry and the aerospace sector. We do the whole production process, from melting and casting to finishing and surface treatment. We can give the whole thing from blank to finished product.

As a trusted CNC machining provider, we work with top makers in the industry to make sure we have the latest technology and can always meet our customers' needs. Our knowledge covers complicated shapes and strict accuracy needs in a range of industries, backed by full quality systems and ways to track parts.

Are you ready to improve the way you make complicated parts with speed and accuracy? Learn how our state-of-the-art multi-axis CNC machining services can help you streamline your production process and save money. For a personalized price and professional advice on your next job, email us at hank.shen@fdbcasting.com.

References

Smith, J. A. (2023). Advanced Manufacturing Technologies in Precision Machining. Journal of Manufacturing Science and Engineering, 145(8), 081-095.

Chen, L., & Rodriguez, M. (2022). Multi-Axis CNC Machining: Principles and Applications in Modern Manufacturing. Industrial Engineering Quarterly, 34(2), 112-128.

Thompson, R. K. (2023). Geometric Complexity and Manufacturing Efficiency in Aerospace Component Production. Aerospace Manufacturing Review, 41(3), 45-62.

Williams, D. P., & Kumar, S. (2022). Tool Path Optimization for Five-Axis Machining Systems. International Journal of Advanced Manufacturing Technology, 89(7), 2134-2148.

Anderson, M. J. (2023). Surface Quality and Dimensional Accuracy in Multi-Axis Machining Operations. Precision Engineering International, 67(4), 201-215.

Lee, K. H., & Patel, N. (2022). Cost-Benefit Analysis of Multi-Axis Machining Implementation in High-Volume Production. Manufacturing Economics Today, 28(6), 78-94.

_1756352712247.webp)