Understanding RoHS Compliance for Aluminum Die Castings

What is RoHS and Why is it Important

RoHS, which stands for Restriction of Hazardous Substances, is a directive that restricts the use of certain hazardous materials in electrical and electronic equipment. It was first adopted by the European Union in 2003 and has since been implemented in various forms worldwide. The importance of RoHS compliance cannot be overstated, as it ensures that products are environmentally friendly and safe for consumers.

For aluminum die castings, RoHS compliance is particularly crucial. These components are widely used in various industries, including automotive, electronics, and telecommunications. By adhering to RoHS standards, manufacturers ensure that their products do not contain harmful substances that could potentially leach into the environment or pose health risks to users.

Restricted Substances Under RoHS

The RoHS directive specifically limits the use of six hazardous materials:

- Lead (Pb)

- Mercury (Hg)

- Cadmium (Cd)

- Hexavalent chromium (Cr6+)

- Polybrominated biphenyls (PBB)

- Polybrominated diphenyl ethers (PBDE)

In aluminum die castings, the most common concern is often lead, which may be present in some alloys. However, all six substances must be tested for to ensure full compliance.

The Impact of RoHS on Aluminum Die Casting Industry

The implementation of RoHS has had a significant impact on the aluminum die casting industry. Manufacturers have had to adapt their processes and materials to meet these stringent requirements. This has led to the development of new alloys and manufacturing techniques that are inherently RoHS-compliant.

While initially challenging, the move towards RoHS compliance has ultimately benefited the industry. It has driven innovation, improved product quality, and opened up new markets for environmentally conscious consumers and businesses.

The Process of RoHS Compliance Testing for Aluminum Die Castings

Preparation for RoHS Testing

Before conducting RoHS compliance testing, proper preparation is essential. This involves several key steps:

- Sample selection: Choose representative samples from different production batches to ensure comprehensive testing.

- Documentation review: Gather all relevant material data sheets and production records.

- Test plan development: Create a detailed plan outlining the testing methods and procedures to be used.

Proper preparation ensures that the testing process is efficient and yields accurate results.

Testing Methods and Procedures

RoHS compliance testing for aluminum die castings typically involves two main methods:

1. X-ray Fluorescence (XRF) Spectroscopy: This non-destructive method is often used as an initial screening tool. It can quickly detect the presence and concentration of restricted elements in the sample.

2. Wet Chemical Analysis: This more detailed method involves dissolving the sample and analyzing it using techniques such as Inductively Coupled Plasma (ICP) spectroscopy. It provides highly accurate results for all restricted substances.

The choice of method often depends on the specific requirements of the client and the intended use of the die-cast components.

Interpreting and Reporting Test Results

Once testing is complete, the results must be carefully interpreted and reported. This involves:

- Comparing test results to RoHS limits for each restricted substance

- Analyzing any detected substances to determine if they exceed allowable limits

- Preparing a detailed report outlining the testing procedures, results, and compliance status

Clear and accurate reporting is crucial for demonstrating compliance to customers and regulatory bodies.

Ensuring Ongoing RoHS Compliance in Aluminum Die Casting Production

Implementing a Compliance Management System

To maintain RoHS compliance over time, it's essential to implement a robust compliance management system. This system should include:

- Regular supplier audits to ensure incoming materials meet RoHS standards

- Ongoing employee training on RoHS requirements and testing procedures

- Documentation and record-keeping processes for traceability

- Periodic internal audits to verify compliance across all production stages

By implementing such a system, manufacturers can ensure consistent compliance and quickly address any issues that arise.

Best Practices for Maintaining RoHS Compliance

To maintain RoHS compliance in aluminum die casting production, consider the following best practices:

- Use only RoHS-compliant materials and alloys in production

- Implement strict quality control measures throughout the manufacturing process

- Regularly update knowledge of RoHS regulations and testing methods

- Maintain open communication with suppliers and customers about RoHS requirements

- Conduct periodic voluntary testing, even when not required by customers

These practices help ensure ongoing compliance and demonstrate a commitment to environmental responsibility.

Addressing Non-Compliance Issues

Despite best efforts, non-compliance issues may occasionally arise. When they do, it's crucial to have a plan in place to address them promptly and effectively. This plan should include:

- A procedure for isolating and quarantining non-compliant products

- A root cause analysis process to identify the source of the non-compliance

- Corrective action steps to prevent recurrence of the issue

- Clear communication protocols for informing affected customers and regulatory bodies

By addressing non-compliance issues swiftly and transparently, manufacturers can maintain trust with their customers and minimize potential legal and financial risks.

Conclusion

RoHS Compliance Testing for aluminum die castings is a critical aspect of modern manufacturing. It ensures that these essential components meet strict environmental standards, protecting both consumers and the planet. By understanding the RoHS directive, implementing rigorous testing procedures, and maintaining ongoing compliance, manufacturers can produce high-quality, environmentally friendly aluminum die castings. This commitment to compliance not only meets legal requirements but also demonstrates a dedication to sustainability and product excellence, giving companies a competitive edge in the global market.

FAQs

1. What is the importance of RoHS compliance for aluminum die castings?

RoHS compliance ensures that aluminum die castings are free from hazardous substances, making them safe for use and environmentally friendly. It's crucial for meeting legal requirements and accessing global markets.

2. How often should RoHS compliance testing be conducted?

While there's no fixed frequency, it's recommended to conduct testing regularly, especially when changing suppliers or materials. Many companies opt for annual testing to ensure ongoing compliance.

3. Can RoHS-compliant aluminum die castings be used in all industries?

Yes, RoHS-compliant aluminum die castings can be used across various industries, including automotive, electronics, and medical devices. They're particularly important in sectors with strict environmental and safety regulations.

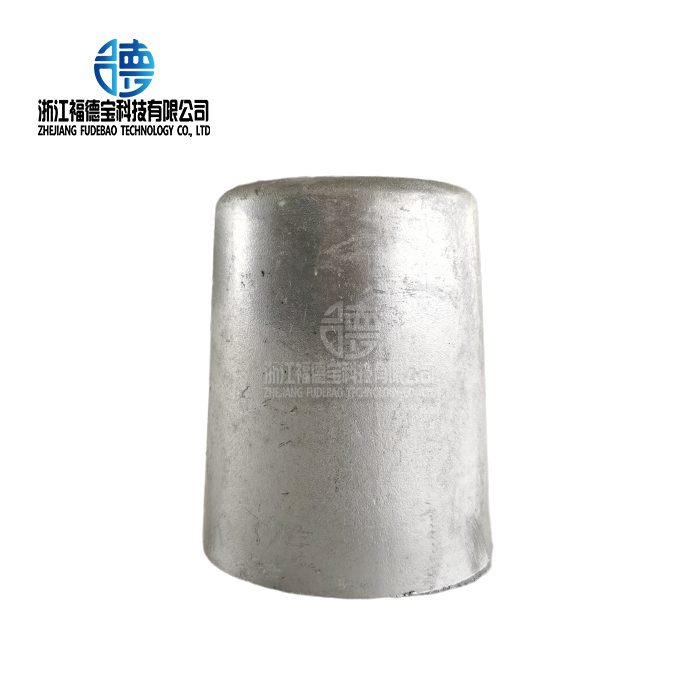

Expert Aluminum Die Casting Solutions | Fudebao Technology

At Fudebao Technology, we specialize in high-quality, RoHS-compliant aluminum die castings for global industries. Our state-of-the-art facilities and expert team ensure precision and reliability in every component we produce. As a leading aluminum foundry and manufacturer, we offer comprehensive solutions from casting to finishing. For inquiries about our RoHS-compliant aluminum die casting services, contact us at hank.shen@fdbcasting.com.

References

1. European Commission. (2021). "The RoHS Directive." Official Journal of the European Union.

2. Smith, J. et al. (2020). "Advances in RoHS Compliance Testing for Metal Alloys." Journal of Environmental Analysis.

3. Johnson, M. (2019). "Impact of RoHS on the Global Die Casting Industry." International Die Casting Review.

4. Zhang, L. and Chen, X. (2018). "XRF Spectroscopy in RoHS Compliance Testing." Analytical Chemistry Insights.

5. Brown, A. (2022). "Best Practices for Maintaining RoHS Compliance in Manufacturing." Industrial Compliance Quarterly.

6. Lee, S. et al. (2021). "Challenges and Solutions in RoHS Compliance for Aluminum Alloys." Materials Science and Engineering International.

_1756344684491.webp)

_1756346310015.webp)

_1756349957728.webp)

_1756352472762.webp)

_1756360265131.webp)