Understanding ASTM B584: Composition and Properties

Chemical Composition of Copper Alloys

ASTM B584 defines the chemical composition requirements for various copper alloys used in sand castings. These alloys typically include copper as the primary element, along with other metals such as tin, zinc, lead, and nickel in specific proportions. The standard covers a wide range of copper alloys, including brass, bronze, and copper-nickel alloys, each with unique properties suited for different applications.

For instance, copper alloy C83600, commonly known as leaded red brass, contains 85% copper, 5% tin, 5% lead, and 5% zinc. This composition provides excellent corrosion resistance and machinability, making it ideal for plumbing fixtures and valve components. Understanding these compositions is crucial for selecting the right alloy for specific casting projects.

Mechanical Properties and Testing Methods

ASTM B584 also specifies the mechanical properties that copper alloy castings must meet. These properties include tensile strength, yield strength, and elongation. The standard outlines testing methods to verify these properties, ensuring consistency and reliability in the final copper castings.

For example, copper alloy C95800, a nickel-aluminum bronze, must have a minimum tensile strength of 90,000 psi and a minimum yield strength of 40,000 psi. These properties make it suitable for marine applications where high strength and corrosion resistance are required in copper castings. Manufacturers must conduct tensile tests according to ASTM E8 to verify compliance with these requirements for copper castings.

Heat Treatment and Microstructure

Some copper alloys covered by ASTM B584 may require heat treatment to achieve desired properties. The standard provides guidelines for heat treatment processes, including temperatures and cooling rates. Additionally, it specifies requirements for microstructure examination, which can reveal important information about the alloy's properties and potential defects.

For instance, certain aluminum bronze alloys may undergo a solution heat treatment followed by controlled cooling to optimize their strength and ductility. The resulting microstructure, typically consisting of alpha and beta phases, can be examined using metallographic techniques to ensure proper heat treatment and predict the alloy's performance.

Applications and Industry Standards

Common Applications of ASTM B584 Copper Alloys

Copper alloys compliant with ASTM B584 find applications across various industries due to their excellent properties. In the marine industry, these alloys are used for propellers, pump components, and valve bodies due to their corrosion resistance in seawater. The automotive sector utilizes copper alloys for bearings, bushings, and other wear-resistant components.

In the plumbing industry, ASTM B584 copper alloys are widely used for fittings, valves, and pump housings. Their resistance to dezincification and stress corrosion cracking makes them ideal for potable water systems. The aerospace industry also benefits from these alloys, using them in landing gear components and hydraulic system parts where high strength and reliability are crucial.

Comparison with Other Industry Standards

While ASTM B584 is a widely recognized standard for copper alloy sand castings, it's important to understand how it relates to other industry standards for copper castings. For instance, the European standard EN 1982 covers similar copper alloys but may have slight differences in composition or property requirements for copper castings. Understanding these differences is crucial for manufacturers serving global markets with copper castings.

Additionally, specific industries may have their own standards that complement or build upon ASTM B584 for copper castings. For example, the American Water Works Association(AWWA) has standards for bronze castings used in water works fittings that reference ASTM B584 but may include additional requirements specific to water distribution systems for copper castings.

Quality Control and Certification

Adherence to ASTM B584 standards requires rigorous quality control measures. Manufacturers must implement testing procedures to verify chemical composition, mechanical properties, and microstructure of their castings. This often involves spectrographic analysis for composition verification, tensile testing for mechanical properties, and metallographic examination for microstructure evaluation.

Certification to ASTM B584 standards can provide a competitive advantage for manufacturers. Many industries require suppliers to provide certification of compliance with ASTM B584, assuring customers of the quality and reliability of the copper alloy castings. This certification process often involves third-party testing and documentation to validate compliance with all aspects of the standard.

Choosing the Right Copper Alloy for Your Project

Factors to Consider in Alloy Selection

Selecting the appropriate copper alloy for a casting project involves considering several factors. The operating environment is crucial; for instance, marine applications may require alloys with high corrosion resistance, while high-temperature applications need alloys with good thermal stability. The mechanical load and wear requirements also play a significant role in alloy selection.

Cost considerations are also important. While some high-performance copper alloys offer excellent properties, they may be more expensive. Balancing performance requirements with budget constraints is essential for cost-effective projects. Additionally, the ease of casting and machinability should be considered, as these factors can significantly impact manufacturing costs and lead times.

Emerging Trends in Copper Alloy Development

Another trend is the development of high-strength copper alloys for demanding applications in aerospace and automotive industries for copper castings. These alloys combine the excellent thermal and electrical conductivity of copper with strength levels approaching those of some steels, opening up new possibilities for lightweight, high-performance components in copper castings.

Working with Copper Alloy Suppliers

Collaboration with experienced copper alloy suppliers is crucial for successful casting projects. A knowledgeable supplier can provide valuable insights into alloy selection, casting design, and manufacturing processes. They can also offer guidance on meeting specific industry standards and certifications beyond ASTM B584.

When working with suppliers, it's important to provide detailed information about the application, including operating conditions, load requirements, and any specific industry standards that must be met. This information helps suppliers recommend the most suitable alloy and casting process for your project, ensuring optimal performance and cost-effectiveness.

Conclusion

FAQs

1. What is the main purpose of ASTM B584 standards?

ASTM B584 sets standards for copper alloy sand castings, specifying chemical composition and mechanical properties.

2. How do ASTM B584 standards benefit manufacturers?

They ensure quality, consistency, and reliability in copper castings, meeting industry requirements.

3. What industries commonly use ASTM B584 compliant copper alloys?

Marine, automotive, plumbing, and aerospace industries frequently use these alloys.

4. How often are ASTM B584 standards updated?

ASTM regularly reviews and updates standards to reflect industry advancements and needs.

5. Can ASTM B584 standards be applied globally?

While widely recognized, some regions may have additional or slightly different standards.

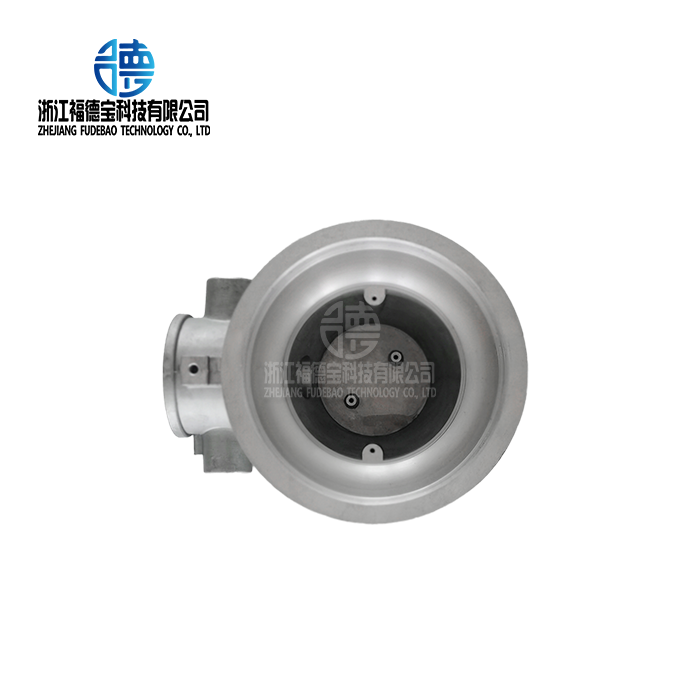

Expert Copper Castings Solutions | Fudebao Technology

At Fudebao Technology, we specialize in high-quality copper alloy castings that meet ASTM B584 standards. Our state-of-the-art foundry and machining facilities ensure precision and consistency in every component we produce. With our expertise in copper alloys and commitment to quality, we're your ideal partner for copper casting projects across various industries. Contact us at hank.shen@fdbcasting.com to discuss your specific requirements and discover how we can deliver superior copper castings for your applications.

References

1. ASTM International. (2021). "ASTM B584-21: Standard Specification for Copper Alloy Sand Castings for General Applications." ASTM Standards.

2. Copper Development Association. (2020). "The Copper Advantage: A Guide to Working with Copper and Copper Alloys." CDA Publication.

3. ASM International. (2019). "Copper and Copper Alloys." ASM Handbook, Volume 2.

4. Journal of Materials Engineering and Performance. (2022). "Recent Advances in Copper Alloy Casting Technologies." Volume 31, Issue 4.

5. American Foundry Society. (2021). "Copper Alloy Casting Design Guide." AFS Technical Publication.

6. Materials Science and Engineering: A. (2023). "Microstructure and Properties of Advanced Copper Alloys for Industrial Applications." Volume 845.

_1756346371362.webp)

_1756349002499.webp)

_1756352340434.webp)