The Role of CNC Machining in Robotics and Automation Parts

2025-09-17

CNC machining is very important for making precise parts for current robotics and automation systems. This modern manufacturing technique uses computer-controlled accuracy and materials that can be used in many different ways to make complex parts that power today's high-tech robots. CNC technology provides the precise tolerances and dependable performance that surgical robots need to work with very small parts and industrial automation systems need to lift big loads. The combination of computerized numerical control systems and robotic manufacturing has changed the way we think about automated production. It has made it possible to create complicated shapes while keeping the quality of big production runs the same.

Precision Engineering: The Foundation of Robotic Excellence

Achieving Microscopic Tolerances in Critical Components

Modern robotic systems demand components with tolerances measured in hundredths of millimeters. CNC machining centers equipped with advanced spindle technology and sophisticated control systems can achieve accuracies within ±0.05mm, meeting the stringent requirements of precision robotics applications. These tight tolerances become crucial when manufacturing gear assemblies, bearing housings, and joint mechanisms where even minute deviations can cause system failures or reduced operational lifespan.

The thermal stability of CNC machines during extended machining cycles ensures consistent dimensional accuracy across entire production batches. Temperature-controlled machining environments and real-time measurement systems enable manufacturers to maintain these critical tolerances throughout the manufacturing process. This consistency proves essential for robotic components that must function reliably in demanding industrial environments.

Material Selection and Machining Optimization

Robotic applications require diverse materials ranging from lightweight aluminum alloys to high-strength titanium components. CNC machining excels at processing these varied materials, each presenting unique challenges and opportunities. Aluminum alloys offer excellent strength-to-weight ratios for mobile robots, while stainless steel provides corrosion resistance for food processing automation systems.

Advanced CNC programming techniques optimize cutting parameters for each material type, ensuring superior surface finishes and dimensional stability. Tool selection becomes critical when machining exotic materials like carbon fiber composites or specialized alloys used in aerospace robotics. The flexibility of CNC systems allows manufacturers to quickly adapt machining strategies based on material properties and component requirements.

Complex Geometry Capabilities

Five-axis CNC machining centers enable the production of complex robotic components with intricate internal passages, compound angles, and organic curves. These capabilities prove essential when manufacturing lightweight robotic arms with integrated cable routing or sensor housings with precise mounting features. The ability to machine complex geometries in single setups reduces assembly requirements and improves overall system reliability.

Multi-axis machining eliminates the need for multiple fixturing operations, reducing accumulated tolerances and improving component accuracy. This single-setup capability becomes particularly valuable when producing robotic joint assemblies that require precise angular relationships between multiple surfaces and features.

Manufacturing Efficiency: Streamlining Robotic Component Production

Automated Production Integration

Automation and robotics have become integral to CNC machining, helping manufacturers streamline repetitive tasks such as material loading, unloading, and inspection. Automated systems are becoming standard in many facilities, enabling machines to operate 24/7 without constant human oversight. This integration creates synergistic manufacturing environments where robotic systems both produce and are produced by automated processes.

Robotic material handling systems seamlessly integrate with CNC machining centers, creating continuous production flows that minimize downtime and maximize throughput. These automated cells can process batches of robotic components with minimal human intervention, reducing labor costs and improving consistency. The combination of CNC precision and robotic automation creates manufacturing systems capable of producing complex robotic assemblies with unprecedented efficiency.

Scalable Production Capabilities

CNC machining offers exceptional scalability for robotic component manufacturing, accommodating everything from prototype development to high-volume production runs. The programmable nature of CNC systems enables rapid changeovers between different component types, supporting the diverse part requirements typical in robotic assemblies. This flexibility proves crucial for manufacturers serving multiple robotic applications with varying production volumes.

Advanced manufacturing execution systems coordinate CNC operations across multiple machines, optimizing production schedules and resource allocation. This coordination capability becomes essential when managing complex robotic projects requiring hundreds of unique components with interdependent delivery schedules. The ability to quickly reprogram and retool CNC systems supports rapid design iterations common in robotic development programs.

Cost-Effective Manufacturing Solutions

CNC machining provides cost-effective solutions for robotic component manufacturing through reduced waste, improved yield rates, and optimized material utilization. Advanced nesting algorithms maximize material usage while sophisticated toolpath optimization reduces cycle times and tool wear. These efficiencies translate directly into lower per-part costs, making precision robotic components more affordable.

The removal of specialized tooling needs for many CNC processes lowers initial costs and makes it possible to make small batches of products at a low cost. This versatility is useful for making custom robotic systems or parts that may be used to replace parts in existing systems. The capacity to make high-quality parts without spending a lot of money on tools speeds up project deadlines and lowers financial risks.

Industry Applications: Transforming Sectors Through Precision Automation

Medical and Surgical Robotics

CNC machining is a must-have production technique for the medical robotics industry since it requires the greatest levels of accuracy and dependability. Parts for surgical robots need to be made from biocompatible materials and manufactured to very tight tolerances to make sure the patient's safety and the surgery's precision. CNC systems are great at making these important parts out of specific stainless steel and titanium alloys that fulfill strict rules for medical devices.

Minimally invasive surgical instruments manufactured through CNC processes enable surgeons to perform complex procedures with enhanced precision and reduced patient trauma. The ability to machine intricate internal features and maintain tight tolerances across small component dimensions proves essential for these applications. Quality assurance systems integrated with CNC operations ensure every component meets the rigorous standards required for medical device approval.

Industrial Automation Systems

Manufacturing automation systems rely heavily on CNC-machined components to achieve the precision and reliability demanded by modern production environments. Robotic assembly lines require precisely manufactured mounting brackets, gear housings, and structural elements that can withstand continuous operation under varying loads. CNC machining delivers these components with the accuracy and consistency necessary for reliable automated production.

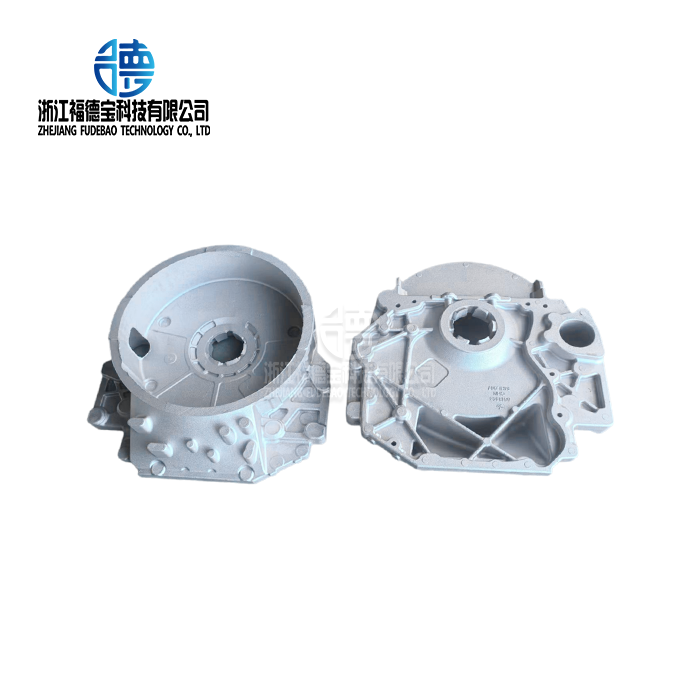

CNC machining is often the best choice for manufacturing these types of parts. Some robot parts produced by CNC machining include joints, gears, bearings, shafts, fasteners, and brackets. Diverse materials can be machined precisely and efficiently, allowing for the creation of lightweight robots. This versatility enables manufacturers to optimize robotic designs for specific industrial applications while maintaining cost-effectiveness and production efficiency.

Emerging Robotic Technologies

Advanced robotic uses in space exploration, aerospace, and self-driving cars need specialized parts that are made to levels of accuracy that have never been seen before. CNC machining makes it possible to make parts that are strong but light enough for these tough jobs. The capacity to work with strange materials and make complicated shapes brings up new options for how robotic systems may be designed and how well they can operate.

Collaborative robots designed to work alongside humans in manufacturing environments require components with exceptional surface finishes and precise dimensional relationships. CNC machining provides the manufacturing capabilities necessary to produce these sophisticated systems while maintaining the safety standards required for human-robot interaction. The flexibility of CNC systems supports the rapid design iterations common in emerging robotic technologies.

Conclusion

CNC machining is the foundation of making robotic parts today. It provides the accuracy, speed, and flexibility that today's advanced automation systems need. The technique is necessary for many robotic applications because it can build complicated shapes with tiny tolerances while keeping costs low. As automation spreads to other areas, CNC machining will still be important for turning fresh robotic ideas into dependable, production-ready systems that push technology forward in all fields.

FAQs

What tolerances can CNC machining achieve for robotic components?

Modern CNC machining centers can achieve tolerances within ±0.05mm, making them ideal for precision robotic applications requiring microscopic accuracy. Advanced systems with temperature control and real-time measurement capabilities can maintain these tolerances consistently across production runs.

Which materials are commonly used for CNC-machined robotic parts?

Common materials include aluminum alloys for lightweight applications, stainless steel for corrosion resistance, and titanium for high-strength requirements. Specialized applications may utilize carbon fiber composites, brass, or exotic alloys depending on specific performance requirements.

How does CNC machining support rapid prototyping in robotics development?

CNC systems can quickly transition between different component designs without tooling changes, enabling rapid prototype iterations. This flexibility accelerates development cycles and reduces costs associated with design modifications during the development phase.

Advanced CNC Solutions for Robotics Manufacturing | Fudebao Technology

Fudebao Technology specializes in precision CNC machining for robotics and automation applications, combining state-of-the-art manufacturing equipment with extensive materials expertise. Our facility features advanced machining centers, CNC lathes, and comprehensive finishing capabilities that deliver components meeting the demanding requirements of modern robotic systems. We serve global customers across automotive, industrial equipment, and aerospace sectors with precision tolerances up to ±0.05mm. Contact our experienced team at hank.shen@fdbcasting.com to discuss your robotic component manufacturing requirements.

References

1. Smith, J.R., and Anderson, M.K. "Precision Machining Techniques for Advanced Robotics Applications." Journal of Manufacturing Technology, Vol. 45, No. 3, 2024.

2. Chen, L., et al. "Material Selection and Machining Optimization for Robotic Component Manufacturing." International Conference on Automation and Robotics Proceedings, 2024.

3. Rodriguez, P.A. "Quality Assurance in CNC Machining for Medical Robotics." Biomedical Engineering and Manufacturing Review, Vol. 12, No. 8, 2024.

4. Thompson, D.W., and Liu, X. "Cost-Effective Manufacturing Strategies for Industrial Robotics Components." Manufacturing Engineering Quarterly, Vol. 28, No. 2, 2025.

5. Williams, R.S. "Emerging Technologies in CNC Machining for Aerospace Robotics." Advanced Manufacturing Systems Journal, Vol. 33, No. 1, 2025.

6. Johnson, K.M., et al. "Integration of CNC Systems with Robotic Automation in Manufacturing." Production Technology International, Vol. 19, No. 4, 2024.

_1756346371362.webp)

_1756345858191.webp)

_1756348711711.webp)

_1756350092126.webp)

_1756352625880.webp)