OEM Sand Casting Services for Industrial Projects

2026-01-16

For industrial projects, OEM sand casting services are a fundamental production solution that turns raw materials into precisely manufactured components in a variety of industries. For both prototype development and large-scale production runs, sand casting offers remarkable adaptability for producing intricate geometries at a reasonable cost. This tried-and-true foundry method is used by industrial producers to create robust metal parts that satisfy the exacting quality requirements and dimensional tolerances needed in the cutthroat market of today.

Understanding OEM/ODM Excellence in Industrial Sand Casting Manufacturing

Basic foundry skills are not enough for modern industrial manufacture. Partnerships between OEMs (Original Equipment Manufacturers) and ODMs (Original Design Manufacturers) create strong cooperative bonds that spur innovation and simplify manufacturing. Selecting a seasoned foundry partner gives you access to extensive technical help that goes beyond basic metal casting tasks.

Manufacturers who comprehend the complex interplay between material science, manufacturing efficiency, and quality assurance are needed in the industrial environment. Because technique can handle different alloy compositions while retaining exceptional dimensional stability during the cooling process, sand casting provides special benefits for industrial applications. This manufacturing process is very useful for creating parts with elaborate exterior features or complicated interior pathways.

Understanding your unique application needs is the first step towards establishing successful OEM collaborations. The ideal foundry partner delivers extensive technical knowledge to every stage of the project, whether you require copper alloy components for heat dissipation systems or aluminum housings for electrical equipment. To optimize part geometry while guaranteeing manufacturability and cost-effectiveness, our engineering team works closely with your design professionals.

Our Comprehensive Sand Casting Manufacturing Strengths

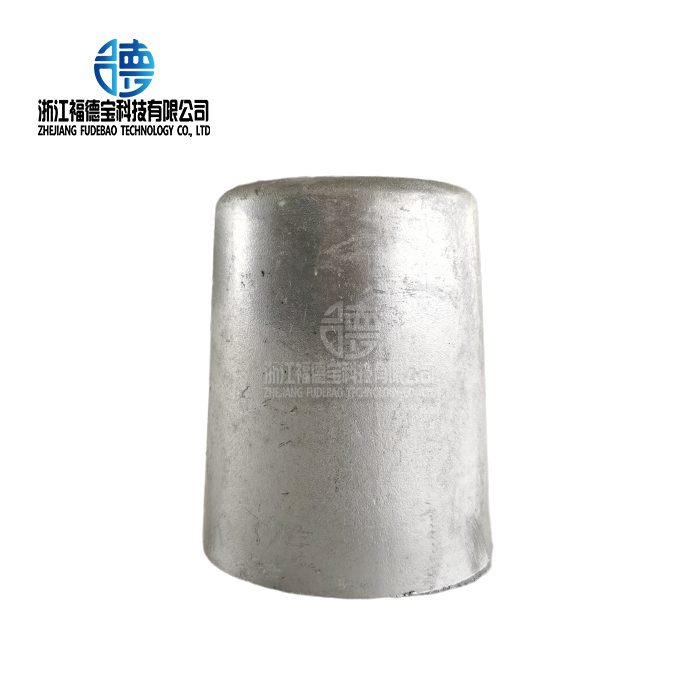

We at Fudebao Technology have established a solid reputation for producing outstanding outcomes in a wide range of industrial applications. With the help of sophisticated machining facilities and precise finishing tools, our foundry can cast stainless steel, copper alloy, and aluminum alloy. From the first mold creation to the last inspection and delivery, this integrated strategy guarantees smooth manufacturing.

CNC lathes, die casting systems, low pressure casting machines, and high-speed machining centers are among the essential equipment in our production facility. The whole "melting-casting-finishing-surface treatment" production chain is supported by this extensive equipment array, allowing for one-stop supply of raw castings to completed components. We routinely satisfy the exacting standards of important industrial applications and automotive precision components with tolerances of ±0.05mm.

Our activities are based on quality management methods. We uphold strict documentation standards, such as complete traceability systems for aerospace applications and PPAP (Production Part Approval Process) compliance for automotive customers. Coordinate measuring devices, spectrometers, and non-destructive testing tools that confirm material characteristics and dimensional correctness are among our inspection capabilities.

We can manage projects ranging from single prototypes to large-scale production runs because to the adaptability of our sand casting procedures. Excellent surface polish and dimensional consistency are provided by green sand molding technologies, while intricate interior geometries are made possible by our core-making skills. Advanced gating system design maximizes material yield and cycle times while reducing casting faults.

Extensive Customization Capabilities for Industrial Applications

The first step in customizing sand casting is choosing materials that are appropriate for your particular operational environment. Aluminum alloys are perfect for automotive and aerospace components because of their superior strength-to-weight ratios and resistance to corrosion. For power equipment and renewable energy applications, copper alloys provide higher electrical conductivity and thermal management qualities.

Our engineering team optimizes part shape for maximum moldability and performance at the crucial customizing stage of pattern development. To guarantee constant dimensional correctness, we take into account elements like draft angles, core positioning, and shrinkage adjustment. Both conventional wooden patterns and contemporary 3D-printed choices for quick prototyping are available in our pattern store.

Customization of mold design includes riser positioning tactics, cope and drag optimization, and flask configuration. Production cycle durations, material efficiency, and casting quality are all directly impacted by these technical factors. Our foundry experts use their decades of knowledge to provide the best molding techniques for your particular component needs.

Options for surface treatment provide even more personalization possibilities to improve performance attributes. While different coating methods enhance electrical conductivity or corrosion resistance, heat treatment procedures might alter mechanical qualities. In order to offer components that precisely match your requirements without the need for further processing, we organize these finishing activities.

The Strategic ODM Advantage in Sand Casting Innovation

Opportunities to co-develop creative sand casting solutions that set your goods apart in cutthroat marketplaces are made possible via ODM cooperation. Together with your engineering experts, our design team develops unique components that maximize performance while preserving production efficiency. Opportunities for cost savings and performance improvements that are not visible in conventional supplier relationships are often revealed by this cooperative approach.

Accelerating product development is a major advantage of ODM, especially when introducing new industrial machinery or improving current designs. Quick design iterations with real production materials and procedures are made possible by our fast prototyping capabilities. This strategy guarantees seamless transitions to full-scale production while lowering development risks.

Through ODM alliances, intellectual property creation may provide significant business benefits. Co-developing breakthrough alloy applications or specific casting procedures allows us to better position ourselves in the market and exchange information. These cooperative inventions often result in improved technological skills and patent potential.

Strategic ODM connections greatly increase market response. Our technical staff keeps an eye on market developments and new technologies, providing insightful information to collaborative development initiatives. This proactive strategy helps in finding new application possibilities and improving current designs to meet changing market demands.

Our Streamlined Sand Casting Development Process

Project initiation for sand casting begins with comprehensive technical discussions to understand your specific requirements, operating conditions, and performance expectations. To create the best casting techniques, our technical team examines current designs, specs, and application information. We provide thorough feasibility studies that include suggested materials, necessary tools, and manufacturing schedules.

Advanced simulation software that forecasts cooling rates, possible flaw sites, and molten metal flow patterns is used to validate designs. These evaluations minimize material waste while optimizing riser location and gating system design. In order to confirm component strength in real-world operating circumstances, we also do stress analysis.

Using materials and procedures intended for manufacturing, prototype development comes after verified designs. Before committing to full production tooling, this phase enables design improvements and performance testing. Throughout the prototype development process, we keep thorough records to guarantee a smooth transfer to mass production.

Process optimization and thorough quality assurance are part of the production ramp-up. To create reliable manufacturing procedures, our team keeps an eye on important process variables including pouring temperature, cooling speeds, and dimensional uniformity. Throughout manufacturing runs, statistical process control systems provide continuous quality stability.

Measurable Benefits for Your Industrial Operations

Significant gains in the bottom line are achieved via cost minimization through smart sand casting collaborations. Our integrated production strategy lowers logistical complexity and inventory carrying costs while doing away with many supplier connections. Cost-effectiveness is further improved by bulk material buying power and efficient production scheduling.

Working with seasoned foundry professionals who comprehend the needs of industrial applications leads to advances in quality assurance. Our statistical process control systems and thorough inspection procedures reduce defect rates while maintaining reliable performance metrics. Field failures and warranty expenses are decreased by this dependability.

Working with a foundry that offers full production solutions simplifies the supply chain. Our one-stop shop for casting, machining, and finishing simplifies coordination and increases delivery dependability. Single-point responsibility speeds up issue solving and simplifies communication.

Advantages of technical assistance in sand casting include continuous engineering cooperation, process optimization advice, and access to metallurgical knowledge. Throughout the product lifetime, our team offers insightful information for design advancements, chances for cost savings, and performance improvements.

FAQs

Which materials are suitable for commercial sand casting processes?

Aluminum alloys (A356, A380, 6061), copper alloys (bronze, brass), and stainless steel grades are among the alloy compositions that sand casting can handle. Application criteria including strength, electrical conductivity, corrosion resistance, and thermal qualities all influence the choice of material. Based on your unique operating circumstances, our metallurgical team makes comprehensive material suggestions.

In what ways does sand casting differ from other industrial foundry techniques?

Sand casting maintains cost-effectiveness for medium to high-volume manufacturing while providing outstanding design freedom for intricate geometries. Sand molds can hold bigger components and different kinds of alloys, unlike die casting. Excellent surface polish and dimensional precision are provided by the technique, making it appropriate for crucial industrial applications.

Which quality requirements are applicable to industrial sand casting processes?

Industry sectors have different standards for quality. TS 16949 compliance and PPAP paperwork are usually necessary for automotive applications. Comprehensive traceability systems and AS9100 certification are required for aerospace components. Applications for industrial equipment concentrate on material qualities, performance testing procedures, and dimensional precision.

How much time does it usually take to create sand casting tools?

Timelines for pattern creation are influenced by prototype needs and component complexity. It might take two to three weeks for simple geometries and six to eight weeks for complicated multi-core systems. Our ability to quickly prototype utilizing 3D-printed patterns may greatly speed up the first stages of validation.

Which design factors maximize the manufacturability of sand casting?

Adequate draft angles (usually 1-3 degrees), suitable wall thickness transitions, and core location consideration are important design elements. The ideal component orientation is further influenced by riser installation specifications and gating system access. Our engineering staff conducts thorough design assessments to maximize manufacturing feasibility while upholding performance standards.

How is dimensional correctness in the fabrication of sand castings ensured?

Precision pattern creation is the first step in dimensional control, which continues via mold preparation, pouring techniques, and cooling control. We maintain statistical process control systems to keep an eye on important dimensions and use coordinate measuring devices to verify inspections. Depending on the size and shape of the component, typical attainable tolerances vary from ±0.5mm to ±0.05mm.

Partner with Fudebao Technology for Superior Sand Casting Manufacturing Solutions

Are you prepared to turn your needs for industrial components into dependable, affordable manufacturing alliances? Fudebao Technology has extensive machining and finishing capabilities along with demonstrated experience in sand casting procedures for aluminum, copper, and stainless steel. Our dedication to accuracy, excellence, and client satisfaction has made us a reliable source for sand castings for manufacturers of industrial machinery, automobiles, and aircraft worldwide. To discuss your unique project needs and learn how our integrated manufacturing solutions may reduce component prices while improving performance dependability, get in touch with our engineering team at hank.shen@fdbcasting.com.

References

Campbell, J. "Complete Casting Handbook: Metal Casting Processes, Metallurgy, Techniques and Design." Butterworth-Heinemann, 2015.

Brown, J.R. "Foseco Non-Ferrous Foundryman's Handbook." Butterworth-Heinemann, 2014.

Stefanescu, D.M. "Science and Engineering of Casting Solidification." Springer International Publishing, 2017.

American Foundry Society. "Sand Casting Manual for Industrial Applications." AFS Technical Publications, 2019.

Beeley, P.R. "Foundry Technology." Butterworth-Heinemann, 2016.

Viswanathan, S. "An Introduction to Metal Casting and Solidification Processing." Materials Research Society, 2018.

YOU MAY LIKE

_1756352712247.webp)