CNC Machining Guide: Materials, Accuracy & Lead Time

2026-01-16

The foundation of contemporary manufacturing is CNC machining, which produces accurate parts for the industrial, automotive, aerospace, and energy industries. When choosing machining partners, engineering management and procurement teams need to consider important factors including reasonable lead time expectations, feasible accuracy requirements, and material selection. This thorough handbook covers all of these topics. Making educated decisions for projects needing dimensional accuracy, material performance, and delivery dependability is made possible by having a solid understanding of these three pillars.

Understanding CNC Machining Fundamentals

CNC machining uses automated, computer-controlled cutting procedures to convert raw materials into completed components. In contrast to traditional manual processes, G-code instructions are executed by CNC systems with exceptional consistency, eliminating human error and preserving tight tolerances across production runs.

Modern machining centers combine drilling, tapping, turning, and milling into a single arrangement. This consolidation speeds up production cycles, lowers cumulative mistakes, and cuts down on handling time. CAD/CAM software creates optimal toolpaths that strike a compromise between material removal rates and surface finish quality, bridging design intent with manufacturing realities.

High-speed machining capabilities have brought about a significant change in the precision manufacturing scene. Modern spindles may reach speeds of above 20,000 RPM, which allows for complex geometries and excellent surface finishes. Without the need for human involvement, automated tool changers can handle a variety of cutting tools and adjust to changing material qualities and feature requirements.

Throughout manufacturing runs, constant dimensional correctness is guaranteed by sophisticated machine calibration systems. Ballbar testing and laser interferometry verify machine operation and spot any positioning mistakes before they affect component quality. For automakers that need PPAP paperwork, these verification processes provide assurance in dimensional repeatability.

Material Selection for Optimal Performance

Because of their remarkable strength-to-weight ratios and superior machinability, aluminum alloys are the most often used in CNC applications. While 7075-T6 offers exceptional strength for aerospace applications, grade 6061-T6 offers balanced mechanical qualities appropriate for structural components. These alloys provide superior surface finishes with less tool wear when machined effectively at high cutting speeds.

Grades of stainless steel provide the corrosion resistance needed in demanding working conditions. While 17-4 PH offers precipitation hardening characteristics for high-strength needs, 316L performs very well in marine applications. Careful tuning of the machining settings is necessary; for example, flood coolant preserves dimensional stability while lower cutting rates avoid work hardening.

Copper alloys are used in electrical applications where temperature control and conductivity are critical. Beryllium copper has both conductivity and spring characteristics, while C101 delivers the highest electrical conductivity. To avoid oxidation during machining processes, these materials need specialized cutting tools and regulated environments.

Titanium alloys provide significant difficulties that need for specific knowledge. Ti-6Al-4V is perfect for aerospace and medical applications because it combines strength and biocompatibility. While chemical reactivity involves careful tool selection and cutting parameter optimization, low thermal conductivity calls for intensive cooling measures.

The range of applications for non-metallic components in CNC machining is increased by engineering plastics. PEEK retains dimensional stability while withstanding high temperatures. Delrin offers mechanical assemblies exceptional resistance to wear. Sharp tools and suitable chip evacuation systems allow these materials to be machined cleanly.

Achieving Precision: Accuracy Standards and Tolerances

Appropriate fixture design and workholding techniques are the first steps toward dimensional precision. Consistent component location is guaranteed throughout manufacturing batches using repeatable clamping systems. By providing consistent clamping stresses, hydraulic workholding prevents thin-walled components from distorting. Modular fixturing methods ensure accuracy while adjusting to different component shapes.

The choice of cutting tool has a direct effect on the quality of the surface finish and the possible tolerances. Tight dimensional control is made possible by carbide end mills with exact grinding tolerances. Throughout prolonged manufacturing cycles, coated tools preserve dimensional consistency and increase tool life. Tool presetting systems eliminate setup inconsistencies by confirming cutting tool dimensions prior to installation.

The precision of machining is greatly impacted by environmental conditions. Both workpieces and machine structures experience thermal expansion as a result of temperature variations. Dimensional stability is maintained in climate-controlled machining environments, which is especially important for big components or lengthy machining cycles. Based on temperature monitoring, thermal compensation systems actively modify machine location.

Throughout manufacturing, dimensional conformity is confirmed by measurement and inspection procedures. Complex geometries may be verified in three dimensions using coordinate measuring machines (CMMs). Real-time dimensional feedback is made possible by in-process probing devices, which automatically adjust for heat drift or tool wear. Trending problems are detected via statistical process control before they affect component quality.

The criteria for surface polish vary greatly depending on the application. Hydraulic components need Ra 0.4 µm or greater, however automotive housings may need Ra 1.6 µm for sufficient sealing performance. The right cutting settings, tool geometry, and finishing techniques are needed to meet these requirements. In spite of changing cut circumstances, adaptive feed management keeps chip loads constant.

Optimizing Lead Times Through Strategic Planning

Project schedules and delivery performance are greatly impacted by production planning. Concurrent engineering techniques are made possible by early supplier participation throughout design stages, which helps to detect any production issues before they affect schedules. While preserving functional requirements, design for manufacturability assessments improve component shapes for effective manufacturing.

Without sacrificing quality, toolpath optimization shortens machining cycle times. While finishing passes attain final dimensions and surface finish criteria, high-efficiency milling procedures remove material quickly during roughing processes. Complex geometries may be produced with fewer setups thanks to 3D machining capabilities, which shortens production times.

Project timelines are impacted by material availability, especially for big plate stock or specialized alloys. Reduced lead times for procurement and reliable supply chains are guaranteed by establishing strategic material relationships. Proactive ordering tactics that avoid production delays are made possible by inventory management systems, which monitor trends in material usage.

Strategies for batch manufacturing strike a compromise between flexibility and efficiency. Dedicated fixtures maximize machine utilization by facilitating quick switchovers between related components. Delivery obligations are maintained by accommodating different component amounts using mixed-batch scheduling. Without requiring significant retooling, flexible manufacturing cells adjust to shifting production needs.

To avoid delays, manufacturing operations for CNC machining are seamlessly integrated with quality assurance procedures. Without taking components out of machining facilities, automated inspection systems provide real-time dimensional feedback. Before committing to full production, first item inspection processes confirm process capabilities. Initiatives for continuous improvement find areas for optimization that shorten cycle times without sacrificing quality.

Industry-Specific Applications and Requirements

Automotive applications need thorough documentation and strict quality requirements. Capability studies, measurement system analysis, and thorough process validation are required under PPAP regulations. Materials that can tolerate high pressures and temperatures are needed for engine parts. While reducing weight, structural components must adhere to crash safety regulations. Cost-effective solutions for high-volume manufacturing are made possible by die-cast integration capabilities.

Durability and dependability are given precedence over long service intervals in industrial equipment components. Pump housings need to be able to hold pressure and withstand corrosion. Accurate bearing surfaces and tooth shapes are required for gearbox components. Applications for heavy machinery need for materials that can survive abrasive conditions and stress loads. Integration of sand casting offers economical solutions for complicated, big geometries.

Applications in the electrical industry prioritize environmental protection, thermal control, and conductivity. Motor housings must have both heat dissipation and electromagnetic shielding qualities. Components of power equipment must be resistant to environmental exposure and electrical arcing. For external installations, precise machining guarantees a good fit and sealing performance. The best electrical performance is made possible by knowledge of copper alloys.

The highest demands for precise production in CNC machining are seen in aerospace applications. Documents proving material traceability demonstrate the chain of custody from raw materials to completed components. Sophisticated examination methods confirm surface quality and interior integrity. Systems of certification show adherence to client requirements and industry norms. While preserving structural integrity, lightweight designs reduce the weight of airplanes.

Advanced Technologies and Future Trends

By fusing the advantages of precision machining and 3D printing, additive manufacturing integration produces hybrid production techniques. CNC operations provide final dimensions and surface finishes for complex interior geometries created by additive methods. This method achieves the necessary dimensional precision while allowing for design freedoms not feasible with conventional production.

Automation technologies increase consistency while lowering labor needs. Robotic loading systems maximize equipment usage by enabling lights-out production capabilities. Production processes include quality assurance via automated part inspection. Systems for predictive maintenance foresee equipment problems before they affect production schedules.

Digital manufacturing platforms use integrated data management to link design, production, and quality systems. Project progress and delivery performance are visible via real-time production monitoring. Global engineering teams may take part in design reviews and problem-solving exercises thanks to cloud-based communication technologies. Using past performance data, artificial intelligence systems enhance cutting settings.

Sustainable manufacturing techniques save operational costs while addressing environmental issues. Coolant usage is decreased while cutting performance is maintained using minimum amount lubrication systems. Energy-efficient machine designs reduce power consumption without sacrificing performance. Programs for recycling extract valuable elements from streams of manufacturing waste. Waste is eliminated across production processes by using lean manufacturing concepts.

Conclusion

Lead time optimization, accuracy requirements, and material selection must all be carefully considered for CNC machining projects to be successful. Engineering teams may make well-informed sourcing selections that balance performance, quality, and delivery expectations by having a thorough understanding of these interrelated aspects. Through technological innovation, modern manufacturing capabilities are constantly improving, providing previously unheard-of levels of accuracy and efficiency for demanding applications in a variety of sectors. These capabilities are unlocked via strategic alliances with seasoned machining suppliers, guaranteeing project success through proven process control, professional material understanding, and dependable delivery performance.

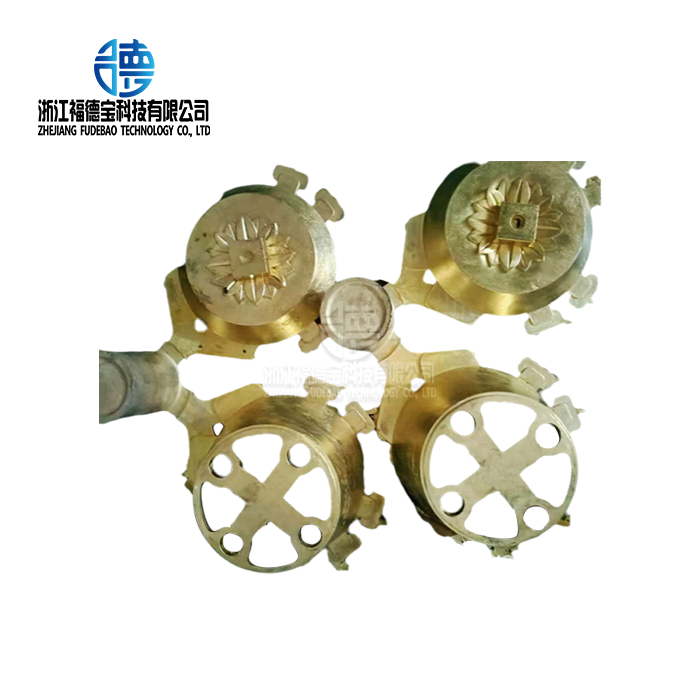

Partner with Fudebao Technology for Precision CNC Machining Solutions

Fudebao Technology delivers precisely machined components that satisfy your most exacting needs by combining cutting-edge production capabilities with extensive industry knowledge. Our cutting-edge facility supports full "melt-to-finish" production with tolerances as low as ±0.05mm thanks to its high-speed machining centers, CNC lathes, and integrated casting capabilities. As a reputable CNC machining company that serves the worldwide automotive, aerospace, industrial, and energy industries, we are aware of how crucial dimensional precision, material performance, and delivery dependability are. To explore your project needs and discover the benefits of Fudebao Technology, get in touch with hank.shen@fdbcasting.com.

References

Smith, John A. "Advanced CNC Machining Techniques for Aerospace Applications." Journal of Manufacturing Technology, vol. 45, no. 3, 2023, pp. 112-127.

Chen, Maria L. "Material Selection Guidelines for Precision Machining Operations." International Manufacturing Review, vol. 28, no. 7, 2023, pp. 89-104.

Rodriguez, Carlos M. "Tolerance Achievement in High-Speed CNC Machining." Precision Engineering Quarterly, vol. 19, no. 2, 2023, pp. 45-62.

Thompson, Sarah K. "Lead Time Optimization Strategies in Modern Manufacturing." Production Management Today, vol. 31, no. 5, 2023, pp. 78-93.

Williams, Robert J. "CNC Programming Best Practices for Complex Geometries." Machining Technology Review, vol. 52, no. 4, 2023, pp. 156-171.

Anderson, Lisa P. "Quality Control Systems in Automated Manufacturing Environments." Manufacturing Excellence, vol. 24, no. 8, 2023, pp. 203-218.

_1756345858191.webp)

_1756348780785.webp)

_1756349794241.webp)

_1756349862928.webp)

_1756360265131.webp)