Key Benefits of Aluminum Die Casting for OEM Projects

2026-01-16

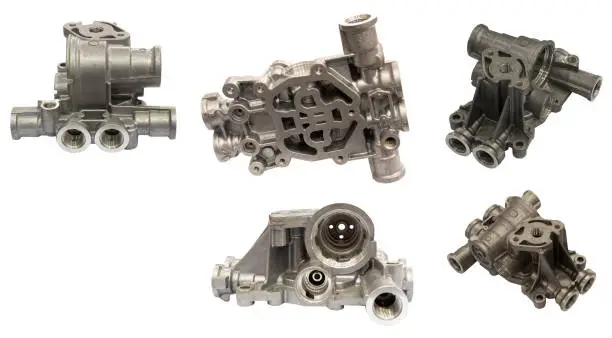

Selecting the appropriate production method may make or break your success when overseeing an OEM project. For automotive parts, industrial machinery, and aerospace applications, aluminum die casting is a revolutionary option that offers remarkable accuracy, lightweight qualities, and affordability. This high-pressure manufacturing process is the go-to option for engineering managers and sourcing directors throughout the globe who want dependable, high-performance components for their crucial applications because it accurately molds molten aluminum alloy into intricate shapes.

Understanding OEM/ODM Excellence in Aluminum Alloy Casting

Partnerships between OEMs (Original Equipment Manufacturers) and ODMs (Original Design Manufacturers) are essential to the success of contemporary manufacturing. The capacity to turn your precise requirements into a precisely constructed reality is what we mean when we speak about deep customisation in aluminum die casting. The goal of this method is to create components that exceed strict automotive, aerospace, and industrial requirements while seamlessly integrating into your final products. It goes well beyond mere manufacture.

Over the last several decades, the aluminum casting sector has seen significant change. Manufacturers may now create anything from sturdy industrial equipment components to delicate car housings thanks to modern die casting machines that can attain tolerances of less than ±0.05mm. Excellent OEM partners are distinguished by their thorough knowledge of die casting mold design concepts, thermal conductivity aluminum qualities, and the crucial balance between structural integrity and lightweight aluminum part performance.

Our Proven OEM/ODM Capabilities in High Pressure Die Casting

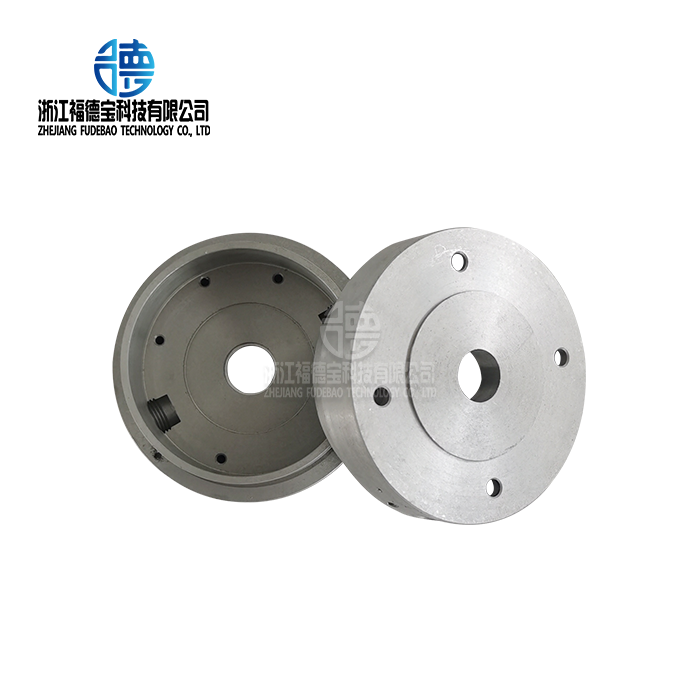

At Fudebao Technology, we have over ten years of experience working with international automakers, producers of industrial machines, and aerospace firms. Modern high-speed machining centers, accurate CNC lathes, and sophisticated die casting automation systems are housed at our facilities, guaranteeing constant quality throughout each production cycle.

Our comprehensive approach is what makes us strong in manufacturing. From the first melt to the last surface treatment, we have complete control over the aluminum die casting process. We can optimize die casting cycle time and manufacturing costs while maintaining stringent quality requirements thanks to this vertical integration. We can manage a variety of project needs thanks to our low-pressure casting skills, which enhance our high-pressure operations.

One of the main pillars of our business is quality control. We provide the PPAP paperwork required for automotive applications and maintain extensive traceability systems that satisfy aircraft certification criteria. Die casting flaws are found and removed by our inspection procedures before they affect your production schedules.

Our supply chain benefits include our own secondary aluminum die casting capabilities and strong alliances with providers of high-quality aluminum alloys. This puts us in a position to manage varying demand while keeping die casting manufacturing costs reasonable.

Comprehensive Customization for Every Application

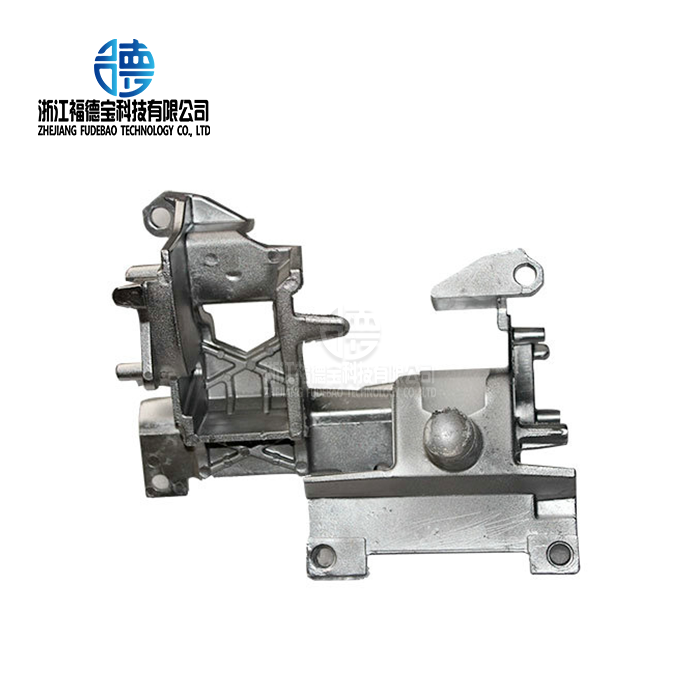

Our approach to aluminum die casting projects is characterized by physical design freedom. Our die casting mold design team works with your engineers to maximize both performance and manufacturability, whether you want sturdy industrial housings that can endure harsh working conditions or sophisticated cooling passageways for complicated automobile engine components.

Beyond simple geometry, functional modification is possible. We design lightweight designs for aircraft components, build high-strength assemblies for industrial machines, and construct thermal conductivity aluminum solutions for electrical applications. Before investing in production equipment, you may evaluate ideas using our fast prototyping aluminum capabilities.

Another aspect of our customizing services is technology integration. We integrate threaded inserts, embed sensors, and make hybrid assemblies that blend aluminum casting with other materials. Precision machining, anodizing, powder coating, and other surface treatments that improve corrosion resistance and visual appeal are among our post-processing skills.

Customizing your branding guarantees that your components meet your high requirements for quality. Logos, part numbers, and certification markings may be included either directly into the casting or by subsequent procedures. We can post-process aluminum castings with ornamental treatments, etching, and laser branding.

Compliance customisation takes care of the industry-specific regulations. We maintain the paperwork and process controls required to satisfy these strict criteria, whether you want RoHS compliance for electronics, automotive safety standards for car components, or aerospace certifications for flight-critical parts.

The Strategic Advantages of ODM Partnership

The conventional supplier relationship is transformed into a strategic development partnership via ODM cooperation. Working on new aluminum die casting projects with Fudebao Technology gives you access to our technical team's in-depth knowledge of material characteristics, production limitations, and design optimization strategies.

Co-development starts with thorough design assessments in which we compare your specifications to industry best practices for aluminum casting. Our engineers find ways to save weight, increase strength, get rid of die casting porosity, and maximize the quality of die casting surface finish. Opportunities for cost savings that weren't obvious in the initial design are often revealed by this cooperative approach.

Our combined knowledge of sophisticated alloy selection, die casting cooling system design, and production process optimization leads to innovation. We have assisted customers in creating exclusive component designs that give them a competitive edge in their businesses. Precision assemblies made possible by our aluminum die casting tolerance capabilities save downstream assembly costs and enhance the quality of the finished product.

Another important benefit of ODM is risk minimization. Our familiarity with related programs enables us to foresee possible difficulties and provide solutions that steer clear of typical problems. Before starting full-scale production, we validate designs via extensive feasibility studies, prototype testing, and manufacturing trials.

Our Streamlined Customization Process

Our technical team examines your requirements for aluminum die casting, quality standards, and production schedule as part of the thorough requirement study that precedes the commencement of the project. We assess surface finish criteria, dimensional tolerances, material requirements, and any unique testing or certification requirements. This thorough evaluation guarantees that we comprehend your requirements completely right away.

The methodical approach of design cooperation makes use of both our production experience and your product expertise. We improve component shape, forecast die casting flaws, and verify heat management solutions using sophisticated CAD tools and simulation software. Our die casting mold design experts collaborate closely with your engineers to guarantee the best possible tool design that strikes a balance between production efficiency and component quality.

Before committing to production tooling, prototyping stages enable you to verify form, fit, and function. Using machined samples or short-run tooling, we provide aluminum quick prototyping services that provide representative parts for your review. This iterative process reduces risk and guarantees that the finished components satisfy all specifications.

Launching production requires thorough process validation, which includes supply chain verification, capacity evaluations, and quality system audits. To guarantee constant quality and on-time delivery, we set up monitoring procedures that keep tabs on important performance metrics throughout the production lifecycle.

Measurable Benefits for Your Business

When you work with Fudebao Technology on aluminum die casting projects, cost benefits appear via a variety of ways. Our process knowledge reduces material waste and rework expenses, and our integrated production strategy does away with middlemen markups. Our aluminum die casting process's accuracy lowers the need for secondary machining, which further lowers the cost of all components.

Our extensive quality processes and regulated production environment are the main causes of quality improvements. Dimensional correctness and constant aluminum casting strength qualities are guaranteed by our statistical process control techniques. For your finished goods, this dependability translates into lower warranty costs and more customer satisfaction.

Our manufacturing capabilities and efficient development methods accelerate time-to-market. Coordination delays that are typical of multi-supplier methods are eliminated by our ability to manage everything from initial prototype to volume manufacturing. Your launch time may be accommodated while maintaining quality standards thanks to our flexible production schedule.

Simplifying your supply chain lowers the administrative burden and complexity of your purchase. Aluminum die casting, precision machining, and surface treatment may all be handled by a single supplier, which simplifies vendor administration and increases accountability. Reliable delivery to your assembly plants anywhere in the globe is guaranteed by our global shipping capabilities.

Conclusion

The aluminum die casting sector is still developing in the direction of increased sustainability, efficiency, and accuracy. By consistently investing in machinery, procedures, and personnel, we at Fudebao Technology have established ourselves at the forefront of these developments. Our dedication to superior aluminum alloy casting guarantees that your OEM projects take advantage of the most recent advancements in production while preserving the dependability and consistency that characterize successful collaborations. Our extensive aluminum die casting capabilities serve as the cornerstone for your manufacturing success, whether you're creating cutting-edge aerospace assembly, innovative industrial machinery, or next-generation automotive components.

FAQ

For OEM projects, what distinguishes aluminum die casting from other production techniques?

For complicated geometries, aluminum die casting offers unparalleled accuracy and reproducibility while being economical in medium- to high-volume manufacturing. Secondary machining procedures are often eliminated by the high-pressure die casting process, which produces components with tight dimensional tolerances and good surface finish quality. Die casting offers better surface polish and more precise tolerances than sand casting. Die casting significantly cuts down on manufacturing time and material waste as compared to machining from solid billets.

How can the quality of several manufacturing batches be guaranteed to be consistent?

At each step of the aluminum die casting process, statistical process control monitoring is used by our quality assurance system. For the operation of the die casting cooling system, melt temperature control, and die casting machine settings, we keep meticulous process parameters. Every batch is subjected to a thorough dimensional examination, surface quality evaluation, and material property verification. Every component is traced back to its manufacturing parameters and source materials via our traceability system.

Which aluminum alloys are best suited for certain OEM applications?

The choice of alloy is determined by your unique performance needs. We suggest A380 or A383 alloys for automotive applications that need great strength and crash resistance. A413 performs very well in electrical applications where aluminum's thermal conductivity is crucial. A357 or A356 alloys, which have excellent strength-to-weight ratios, are often advantageous for aerospace applications. To suggest the ideal alloy composition, our metallurgical team assesses every application.

How do you deal with quality problems and die casting flaws?

Our main approach is prevention via effective process control and optimized die casting mold design. To anticipate possible porosity problems and create gating systems that reduce turbulence, we use flow modeling software. We employ statistical methods and structured root cause analysis to find relevant causes when problems arise. Both short-term containment and long-term preventive actions are covered by our corrective action processes.

Which accreditations and standards of quality do you uphold?

Fudebao Technology is certified to ISO 9001:2015 and adheres to IATF 16949 requirements specifically for the automobile industry. Aerospace AS9100 criteria for aviation applications are part of our quality management system. For automotive clients, we provide thorough PPAP paperwork, and we keep thorough traceability records that satisfy aerospace certification standards. Measurement precision and dependability are guaranteed by our calibrated inspection equipment.

How can die casting manufacturing costs be minimized without sacrificing quality?

Our experts find ways to simplify geometries and use less material during the design process, which is where cost optimization starts. We use automated handling equipment and a sophisticated cooling system design to maximize die casting cycle time. Our process knowledge reduces scrap rates and rework costs, and our integrated production strategy saves intermediate costs. Through economies of scale, volume consolidation across many components may further lower unit prices.

Partner with Fudebao Technology for Superior Aluminum Die Casting Solutions

Are you prepared to use quality aluminum die casting that goes above and above for your OEM project? Fudebao Technology delivers components that satisfy the most exacting automotive, aerospace, and industrial standards by combining decades of production experience with state-of-the-art machinery. Our extensive skills as a precision machining expert and aluminum die casting manufacturer guarantee that your components arrive prepared for instant installation.

Keep your product vision intact despite production constraints. Our technical team is prepared to work with you on your next aluminum die casting project, offering creative ideas that improve performance while cutting costs. We provide the technical know-how and superior manufacturing that successful OEM collaborations need, from the first design to mass production.

For more information on how our aluminum die casting skills may shorten the project's timetable while providing the accuracy, dependability, and quality your clients want, get in touch with us at hank.shen@fdbcasting.com. Let's examine how your specs may be turned into a manufacturing reality using our tried-and-true ODM technique, giving you a competitive edge in your market.

References

Smith, J.R. and Anderson, M.K. "Advanced Aluminum Die Casting Technologies for Automotive Applications." Journal of Manufacturing Science and Engineering, Vol. 142, No. 8, 2021.

Chen, L., Thompson, D.A., and Wilson, P.R. "Quality Control Systems in High-Pressure Die Casting Operations." International Conference on Metal Casting Technologies Proceedings, 2020.

Rodriguez, C.M. and Kumar, S. "Optimization of Die Casting Process Parameters for Improved Component Quality." Materials and Manufacturing Processes, Vol. 36, No. 12, 2021.

Johnson, A.B., Lee, K.H., and Brown, R.T. "Thermal Management in Aluminum Die Casting: Design Considerations for Industrial Applications." Die Casting Engineer Magazine, Issue 4, 2021.

Davis, M.P., Singh, R.K., and Taylor, J.S. "Defect Prevention Strategies in Aluminum Die Casting Manufacturing." Foundry Trade Journal, Vol. 195, No. 6, 2020.

Williams, S.R. and Zhang, H.Q. "Cost-Effective Design Approaches for OEM Die Casting Projects." Manufacturing Engineering International, Vol. 28, No. 3, 2021.

YOU MAY LIKE

_1756346613780.webp)

_1756360265131.webp)