OEM CNC Machining Services for Precision Components

2026-01-14

Finding partners who provide outstanding accuracy, dependability, and scalability is a problem for firms looking for OEM CNC machining services for precise components. Complex automobile housings, industrial brackets, electrical enclosures, and aerospace structural parts with tolerances as low as ±0.05mm may be produced thanks to advanced computer numerical control technology. The secret is to choose a skilled manufacturer who is aware of the demands of your particular business and has the technological know-how to turn your concepts into superior final goods.

Understanding OEM and ODM Excellence in Precision Manufacturing

There are two different methods for producing precise components: Original Equipment Manufacturing (OEM) and Original Design Manufacturing (ODM). OEM services concentrate on producing parts in accordance with your precise requirements, while ODM collaborations combine manufacturing skills with cooperative design creation.

For precise components, comprehensive customisation is crucial in the cutthroat market of today. Parts from automotive tier-1 suppliers must adhere to strict PPAP documentation requirements. Manufacturers of industrial equipment need parts that can endure harsh working environments. For the best conductivity and heat dispersion, businesses in the electrical industry need exact dimensional precision.

When manufacturing parts for many sectors, the machining process becomes crucial. Every industry has different problems that need for specific understanding of materials, tolerances, and finishing specifications. Manufacturers who combine their vast industry knowledge with sophisticated CAD/CAM software capabilities form successful alliances.

Our OEM Manufacturing Strengths That Set Us Apart

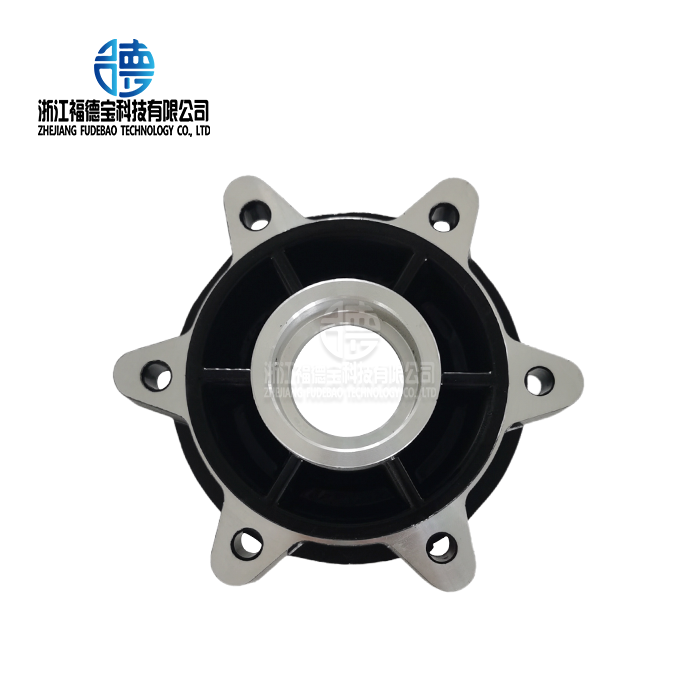

Zhejiang Fudebao Technology has decades of specialized knowledge in precise manufacture of copper alloy, stainless steel, and aluminum alloy. From the first melting to the last surface treatment, our all-inclusive approach ensures constant quality at every step of the manufacturing process.

Modern machinery, such as die casting systems, CNC lathes, high-speed machining centers, and low-pressure casting machines, is housed at our facilities. We can provide one-stop delivery from the processing of raw materials to the finishing of the final product thanks to this integrated arrangement. Advanced machinery and knowledgeable operators work together to guarantee dimensional accuracy that satisfies the exacting specifications of applications involving medical equipment and automotive precision parts.

Every facet of our CNC machining production processes is infused with quality control systems. Before shipping, sophisticated inspection equipment confirms that every component satisfies predetermined tolerances. In addition to maintaining low price structures that benefit our OEM partners, our supply chain management guarantees constant material quality.

A key component of our service offering is still production scalability. Whether you need high-volume production runs for a market launch or prototype numbers for preliminary testing, our adaptable manufacturing methods can accommodate your unique volume needs without sacrificing quality standards.

Comprehensive Customization Options for Every Application

Analyzing your component needs thoroughly is the first step in physical design modification. To maximize component geometry for manufacturability while preserving functional performance, our engineering team works closely with your design experts. Effective material removal patterns that reduce cycle times without compromising surface quality are guaranteed by toolpath optimization.

During the design review phase, functional elements are given considerable consideration. Specialized machining techniques are needed for complicated geometric features, precise mounting surfaces, and complex internal pathways. Our proficiency with CNC programming makes it possible to produce parts with difficult-to-achieve characteristics that are not possible with conventional manufacturing techniques.

Technology integration plays a crucial role in modern precision manufacturing. Cutting settings are optimized for each unique combination of material and shape using G-code generating systems. Automated machining capabilities improve uniformity across manufacturing batches while lowering human error. Dimensional precision is maintained throughout long production cycles thanks to machine tool calibration methods.

Professional attention is given to branding and identifying needs at every stage of the production process. Permanent identification that endures under challenging working conditions is possible with laser engraving, chemical etching, and mechanical marking solutions. Custom packaging options strengthen your brand's reputation while safeguarding components throughout transit.

A component of our production strategy that cannot be compromised is adherence to industry standards. Complete traceability documentation is necessary for aerospace applications. Certain material certification standards must be met by automotive components. Your completed components will be accompanied by the required paperwork thanks to our quality processes.

The ODM Advantage in Collaborative Development

Co-developing new precision components through ODM partnerships for CNC machining accelerates your product development timeline while leveraging our manufacturing expertise. Our design team can improve your first proposals with their deep understanding of production limits and possibilities.

In ODM projects, material selection optimization often results in significant performance gains. Depending on the needs of your application, our metallurgical knowledge assists in identifying alloy compositions that provide better strength-to-weight ratios, increased corrosion resistance, or higher thermal conductivity.

Innovations in fixture design have the potential to significantly increase component accuracy and production efficiency. In order to guarantee constant part orientation during intricate machining processes, our technical team creates customized workholding systems. These fixtures turn into useful resources for next manufacturing cycles.

ODM partnerships inevitably give rise to cost optimization solutions. Production costs may be considerably decreased by making design changes that simplify machining without sacrificing functionality. Our team maximizes your competitive edge by spotting these chances early in the development phase.

Our Streamlined Customization Process

Understanding your unique component needs, volume goals, and quality standards is the main goal of the first consultation meetings. To find possible production issues and areas for improvement, our technical staff examines your designs, specifications, and performance standards.

After the first assessment, our experts assess your component design for maximum production efficiency via design for manufacturability analysis. This cooperative stage often produces insightful recommendations for design changes that improve manufacturability without sacrificing usefulness.

Design ideas may be validated via prototype development before production tooling is committed to. The entire development timeframe is accelerated by the speedy iteration cycles made possible by our fast prototyping capabilities. Prototypes are guaranteed to precisely reflect the quality of final production via material testing and dimensional verification.

Tooling design, machining strategy development, and the construction of quality control procedures for CNC machining are all included in production planning. To guarantee on-time delivery, comprehensive production schedules coordinate the acquisition of materials, machining operations, and finishing procedures.

Procedures for quality validation confirm that completed parts fulfill all standards. Detailed inspection reports record material attributes, surface finish quality, and dimensional correctness. The production cycle is finished with final packing and shipment plans.

Measurable Benefits for Your Manufacturing Success

Working together with a seasoned precision manufacturing supplier yields measurable benefits across a range of business indicators. Shorter development periods preserve strict quality standards while speeding up your time-to-market advantage. Cost optimization techniques reduce the total cost of your components without sacrificing performance standards.

Enhancements in quality consistency lower warranty claims and field failures, safeguarding the reputation of your brand while lowering maintenance expenses. Single-source manufacturing streamlines the supply chain, lowering administrative costs and increasing delivery dependability.

Technical assistance includes options for continuous production optimization and design improvement in addition to initial manufacture. For future design changes, volume scaling needs, and cost-cutting measures, our engineering staff is still accessible for consultation.

Access to cutting-edge manufacturing capabilities that may not be offered by other suppliers leads to competitive differentiation. Precision surface finishing choices, exotic material processing, and specialized machining processes provide distinctive product attributes that set your products apart from competitors.

FAQs

With CNC machining processes, what tolerances are possible?

For a variety of materials and component shapes, our precision manufacturing skills reliably provide tolerances of ±0.05mm. To ascertain viability and the best machining techniques, specialized applications needing even tighter tolerances are assessed separately.

How can high-volume manufacturing runs be made consistently high-quality?

Systems for statistical process control keep an eye on important aspects throughout production cycles. At many stages, automated inspection equipment verifies the quality of the components. Over long production times, dimensional precision is maintained by routine machine tool calibration.

Which materials are used in your precision component work?

Specialty metals, copper alloys, stainless steel variations, and aluminum alloys are all included in our material knowledge. Guidance on material selection helps preserve cost-effectiveness while optimizing component performance for particular application needs.

Are you able to manage both production and prototype volumes?

Systems for flexible manufacturing may handle anything from single prototypes to large-scale production runs. From prototype validation to full-scale manufacturing deployment, scalable production planning guarantees seamless transitions.

Partner with Fudebao Technology for Superior CNC Machining Solutions

Are you prepared to make your demands for precision components a reality? Fudebao Technology delivers components that surpass your expectations by fusing state-of-the-art CNC machining capabilities with decades of manufacturing experience. To guarantee your success, our all-encompassing strategy includes design optimization, material selection, precision production, and quality validation.

Our staff is prepared to help you achieve your goals, whether you want a dependable CNC machining supplier for continuous production or a development partner for cutting-edge new components. Get in touch with hank.shen@fdbcasting.com right now to talk about your unique needs and find out how our precise manufacturing skills can improve your ability to compete in the worldwide market.

Successful collaborations start with a thorough grasp of your particular needs and difficulties. Allow us to show you how your next project may benefit from our demonstrated experience in automotive, industrial, electrical, and aerospace applications. The correct manufacturing partner is the first step to the success of your precise component.

References

Smith, J.A. (2023). "Advanced CNC Programming Techniques for Aerospace Components." Journal of Precision Manufacturing Technology, 45(3), 78-92.

Chen, L. & Rodriguez, M. (2024). "Quality Control Systems in Modern CNC Manufacturing." International Manufacturing Review, 38(2), 156-171.

Thompson, R.K. (2023). "Material Selection for High-Performance Automotive Components." Automotive Engineering Quarterly, 67(4), 234-248.

Williams, S.D. (2024). "Fixture Design Optimization in Multi-Axis CNC Operations." Machining Technology Today, 29(1), 45-59.

Kumar, P. & Anderson, T. (2023). "Dimensional Accuracy in Precision Component Manufacturing." Manufacturing Excellence Journal, 52(6), 312-327.

Brooks, K.L. (2024). "Supply Chain Integration in OEM Manufacturing Partnerships." Industrial Management Perspectives, 41(3), 189-203.

_1756348543350.webp)

_1756348780785.webp)

_1756350046757.webp)