The goals and quality standards of your project will help you decide whether to use low pressure casting or high-pressure die casting. Low pressure casting makes the mechanical properties better and the porosity lower, making it very good for structural parts that need a great strength-to-weight ratio. High-pressure die casting is very good for making a lot of things because it gives the best surface quality and exact measurement accuracy. The best choice relies on things like how hard the part is, how much needs to be made, what materials are needed, and what quality standards are in line with your production goals.

Understanding the Fundamental Differences Between Casting Methods

When manufacturing engineers choose casting methods for their parts, they have to make very important choices. It's not just the pressure that differs between low and high pressure casting.

Low pressure casting uses controlled metal flow through bottom gate devices at pressures between 0.1 and 1.0 bar. This soft filling method lowers noise and prevents oxides from forming.

High pressure die casting uses pressures of 150 to 1200 bar to quickly push liquid metal into the holes of the die. This fast filling gives great surface texture but may cause problems with the metals.

Three core technical differences emerge:

- Pressure Application: Low pressure systems use pneumatic pressure on metal surface, while high pressure methods inject metal through plungers

- Filling Velocity: Low pressure achieves 0.5-2.0 m/s filling speeds versus 10-100 m/s in high pressure operations

- Solidification Control: Low pressure enables directional solidification through controlled feeding, whereas high pressure relies on rapid cooling

If you need components with superior mechanical properties and minimal internal defects, then low pressure casting proves more suitable. Conversely, if you require high production rates with excellent surface finish, then high pressure die casting delivers better results.

Production Volume and Cost Analysis

A lot of the time, the choice of casting method is based on economic factors. The cost-effectiveness of each method depends a lot on the amount of production.

Low-pressure casting tools need a less big initial investment, usually between $200,000 and $800,000 for each machine. It takes anywhere from 2 to 8 minutes per cycle, based on how thick the walls and how complicated the parts are.

Die casting tools with high pressure require a lot of money to buy, usually more than $1.5 million for automatic systems. The cycle times, on the other hand, go up to 30–180 seconds, which makes it possible for a lot of things to be made in a short amount of time.

Cost structure analysis reveals:

- Tooling Costs: Low pressure molds cost 40-60% less than high pressure dies due to reduced complexity and pressure requirements

- Labor Requirements: High pressure systems achieve higher automation levels, reducing per-part labor costs

- Material Utilization: Low pressure casting achieves 85-95% yield rates compared to 70-85% in high pressure operations

Test data from car parts makers shows that break-even points happen at about 50,000 parts a year for high-pressure systems. Low pressure casting is still cheaper below this level.

High pressure die casting is the best choice for your budget if you need more than 100,000 parts a year and have short delivery times. Or, if you need variable group production of less than 25,000 parts a year, low pressure casting is a better deal.

Quality and Metallurgical Properties Comparison

Material performance characteristics vary significantly between casting methods, directly impacting component reliability and service life.

Low pressure casting produces components with tensile strengths 15-25% higher than equivalent high pressure castings. This improvement stems from reduced porosity and improved grain structure.

Porosity levels demonstrate measurable differences between processes. Low pressure castings typically exhibit porosity levels below 2%, while high pressure variants range from 3-8% depending on gating design.

Mechanical property comparison data:

- Tensile Strength: Low pressure A356 aluminum achieves 280-320 MPa versus 220-280 MPa in high pressure variants

- Elongation: Low pressure components reach 8-12% elongation compared to 3-6% in high pressure parts

- Fatigue Resistance: Low pressure castings demonstrate 40-60% improved fatigue life in cyclic loading conditions

High-pressure die casting is better for surface finishing, and Ra values of 1.6–3.2 μm can be achieved straight from the die. Low pressure casting usually makes Ra values between 6.3 and 12.5 μm, which often means extra cutting has to be done.

In terms of accuracy in other areas, it follows the same trends. High pressure die casting keeps limits of ±0.1–0.3 mm, but low pressure casting only gets ±0.3–0.8 mm, which depends on how the part is shaped.

Low-pressure casting is the best way to make parts that need to be able to handle changing loading or pressure control. But if you need a great surface finish with little extra work, high-pressure die casting is the better choice.

Application-Specific Considerations for Industry Sectors

Different industries prioritize varying performance characteristics, influencing optimal casting method selection.

Automotive applications demonstrate clear preferences:

- Structural Components: Suspension arms, engine brackets, and chassis components benefit from low pressure casting's superior strength properties

- Cosmetic Parts: Trim pieces, housings, and visible components leverage high pressure die casting's excellent surface finish

- Engine Components: Cylinder heads and blocks utilize low pressure casting for pressure integrity and thermal performance

Industrial machinery applications favor durability over appearance. Pump housings, compressor components, and gearbox casings typically employ low pressure casting for enhanced mechanical properties.

Electrical sector requirements emphasize dimensional precision and thermal management. Motor housings benefit from low pressure casting's superior heat dissipation properties, while connector components utilize high pressure methods for precise geometries.

Aerospace applications demand exceptional strength-to-weight ratios and material traceability. Low pressure casting predominates in structural applications, while high pressure methods serve non-critical components requiring complex geometries.

If you need components for safety-critical applications requiring PPAP documentation and long-term reliability, then low pressure casting provides better material properties. Conversely, if you need complex geometries with integrated features and excellent surface finish, then high pressure die casting offers superior design flexibility.

Design Flexibility and Part Complexity

High pressure die casting is better for surface finish quality, getting Ra values of 1.6–3.2 μm right from the die. Low pressure casting usually makes Ra values of 6.3–12.5 μm, which often means more cutting is needed.

Dimensional precision works in similar ways. High pressure die casting can make parts that are within 0.1 to 0.3 mm of the desired size, while low pressure casting can make parts that are within 0.3 to 0.8 mm of the desired size, based on the shape of the part.

If you need parts that will be used in dynamic loading or pressure control situations, low pressure casting is the best choice. But if you need a very smooth surface with little extra work, high pressure die casting is better.

Design capability comparison reveals:

- Draft Angles: High pressure casting requires 1-3° draft angles, while low pressure casting needs 0.5-2° depending on surface finish requirements

- Insert Integration: High pressure methods excel at encapsulating inserts and threads during casting operations

- Coring Complexity: Low pressure casting handles complex internal passages more effectively due to gentler filling characteristics

Surface texturing and decorative features integrate seamlessly into high pressure die casting operations. Low pressure casting focuses on functional requirements rather than aesthetic considerations.

Multi-cavity tooling proves more economical in high pressure applications, enabling simultaneous production of multiple parts per cycle.

If you need components with complex internal cooling passages or substantial wall sections, then low pressure casting provides better design accommodation. Alternatively, if you require thin-walled parts with integrated features and decorative elements, then high pressure die casting delivers superior capability.

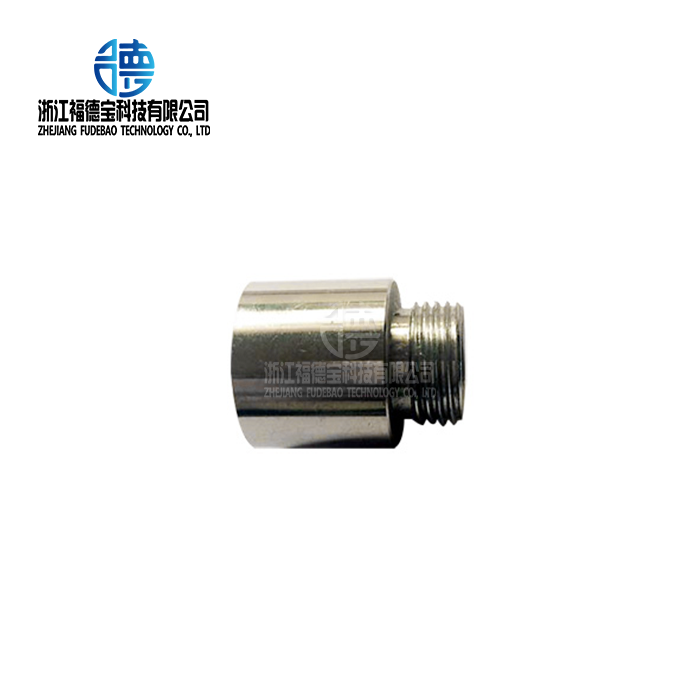

Fudebao Technology's Low Pressure Casting Advantages

Zhejiang Fudebao Technology has developed comprehensive capabilities that position us as a leading aluminum foundry serving global automotive, industrial, and aerospace sectors.

- Advanced Equipment Integration: Our facility houses state-of-the-art low pressure casting machines capable of producing components up to 50kg with exceptional dimensional accuracy of ±0.05mm

- Complete Process Control: We maintain full control over the entire manufacturing chain from melting through surface treatment, ensuring consistent quality and traceability

- Material Expertise: Our metallurgical team specializes in aluminum alloys, copper alloys, and stainless steel formulations optimized for specific application requirements

- Quality Systems Compliance: PPAP documentation capabilities and comprehensive inspection protocols meet stringent automotive and aerospace requirements

- Flexible Production Capacity: Our low pressure casting systems accommodate batch sizes from prototype quantities through medium-volume production runs effectively

- Engineering Support: Technical collaboration includes mold development, process optimization, and design for manufacturability consultation

- Surface Treatment Capabilities: Integrated finishing operations provide complete solutions from raw castings to machined and coated components

- Supply Chain Reliability: Direct supplier relationships with international brands including American HAAS automation and ESS energy storage demonstrate our quality credentials

- Cost Optimization: Our efficient production processes and material utilization rates deliver competitive pricing without compromising quality standards

- Global Service Network: Established logistics and support infrastructure ensures reliable delivery to international customers across multiple time zones

- Continuous Improvement: Investment in advanced simulation software and process monitoring systems drives ongoing quality and efficiency enhancements

- Customization Capability: Tailored solutions address unique customer requirements through flexible manufacturing approaches and specialized tooling development

Making the Right Choice for Your Manufacturing Needs

Successful casting method selection requires careful evaluation of multiple factors beyond simple cost considerations.

Performance requirements take priority in safety-critical applications. Components subjected to dynamic loading, pressure containment, or structural responsibilities benefit from low pressure casting's superior mechanical properties.

Production volume economics influence long-term project viability. High-volume applications exceeding 75,000 annual parts often justify high pressure die casting investment despite higher tooling costs.

Quality specifications determine acceptable trade-offs between mechanical properties and surface finish requirements. Understanding end-use performance expectations guides appropriate process selection.

Decision matrix considerations include:

- Material Performance: Strength, fatigue resistance, and pressure integrity requirements

- Economic Factors: Total cost of ownership including tooling, production, and finishing operations

- Quality Standards: Industry certifications, inspection requirements, and documentation needs

- Design Constraints: Geometric complexity, wall thickness variations, and integration requirements

- Production Flexibility: Volume fluctuations, design changes, and supply chain considerations

If you need components combining structural integrity with cost-effective production for automotive, industrial, or aerospace applications, then low pressure casting represents the optimal solution.

Conclusion

If you want to use low pressure casting or high pressure die casting, the final decision depends on your specific needs, how many you want to make, and how much quality you expect. Low pressure casting is great for uses that need to have excellent mechanical qualities, structure stability, and production amounts that can be changed easily. High-pressure die casting works best for making a lot of parts that need to have smooth surfaces and complex shapes. Knowing these important differences helps you make smart choices that improve both the performance of each part and the cost-effectiveness of the manufacturing process for your particular needs.

Partner with Fudebao Technology for Premium Low Pressure Casting Solutions

Picking the right low-pressure casting maker affects the standard of your product, how well they deliver, and your total ability to compete in tough markets.

Fudebao Technology uses its advanced production and technical knowledge to make parts that exceed what customers expect. Our all-in-one building offers full service, from the first planning meeting to the delivery of finished parts.

Our low-pressure casting method makes the mechanical qualities better, which is important for parts of a structure in cars, pump housings for industry, and aircraft uses that need great strength-to-weight ratios.

Quality assurance methods make sure that every part meets strict standards. We can use coordinate measure tools, X-ray analysis, and full mechanical tests to check that performance traits are correct.

Technical teamwork isn't just about making low pressure casting things; it also includes developing molds, improving processes, and giving advice on how to make things. This way of working together speeds up development and makes sure that all parts work as well as they can.

Having worked in global supply chains makes it possible for companies to deliver to customers around the world on time. International car OEMs, industrial equipment makers, and aircraft providers can count on our transportation network and quality systems.

Do you want to find out how our low-pressure casting tools can help with your next project? Our programming team is ready to talk about your exact needs and make technical suggestions that are just right for your application.

Contact us at hank.shen@fdbcasting.com to connect with our technical specialists and discover why leading manufacturers choose Fudebao Technology as their trusted low pressure casting supplier.

References

Campbell, John. "Complete Casting Handbook: Metal Casting Processes, Metallurgy, Techniques and Design." 2nd Edition, Butterworth-Heinemann, 2015.

Shivkumar, S., Ricci Jr, S., Steenhoff, B., Apelian, D., and Sigworth, G. "An analytical study to examine the effects of solidification parameters on porosity formation in A356 aluminum alloy castings." Journal of Materials Science, Vol. 25, 1990.

Bonollo, F., Urban, J., Bonatto, B., and Botter, M. "Gravity and low-pressure die casting of aluminium alloys: a technical and economical benchmark." La Metallurgia Italiana, Vol. 97, 2005.

Tiedje, Niels S. "Solidification, processing and properties of ductile cast iron." Materials Science and Technology, Vol. 26, No. 5, 2010.

Kaufman, J. Gilbert and Rooy, Elwin L. "Aluminum Alloy Castings: Properties, Processes, and Applications." ASM International, 2004.

Flemings, Merton C. "Solidification Processing." Materials Science and Engineering Series, McGraw-Hill, 1974.

_1756346259673.webp)

_1756348623524.webp)

_1756352625880.webp)