Anodizing, powder coating, grinding plus clear coating, and polishing are the best ways to finish the surfaces of aluminum wheels that are made at low pressure casting. These processes make the object more durable, more resistant to rust, and more aesthetically pleasing while keeping the strength that low-pressure casting gives it. Each style has its own set of perks for various wheel uses and performance needs.

The Importance of Surface Finishing

When making metal wheels that work well, the quality of the surface finish affects how they look and how long they last. Low pressure casting is a new way to make wheels that works much better than older methods because it makes the material denser and stronger. The managed filling process makes wheels that meet the strict standards of the car industry and gets rid of porosity problems at the same time.

Surface finishing is the last step in making wheels. It takes the rough casts and makes them into goods that are ready to be sold. The chosen finish must hold up against rough roads, changes in temperature, exposure to salt, and wear and tear from daily use. Car companies today want wheels that look the same after a long time of being used and that help make cars lighter. Engineers and buying teams make good choices about cost, performance, and appearance when they know about surface processes that work well with low-pressure cast aluminum.

Why Focus on Surface Finishes for Low Pressure Cast Wheels?

The car business always looks for new ways to make wheel shapes that are lighter, stronger, and more beautiful. Low pressure casting gives you great material qualities that make high-quality surface processes possible. This way of making wheels gives them a consistent grain structure and very few flaws, which makes it easier to use a range of finishing methods.

Surface finishes prevent aluminum wheels from environmental damage and make them look nicer. Aluminum naturally rusts when it comes on contact with air. This creates a protected layer that stops further rusting. However, this natural rust doesn't look shiny; it looks even and dull. Professional finishing methods either stop this rust or cover it up with coats that look and protect better.

The world wheel market needs finishes that work in a variety of temperatures and on a variety of road situations. Wheels need to keep their shape and look, even when they are in places with very cold winters where salt is used a lot or in warm places where there is a lot of humidity. The benefits of low pressure casting include fewer holes and better surface quality. These wheels are perfect for high-end finishing methods that car manufacturers and customers expect.

Selection Criteria for Optimal Surface Finishes?

There are a number of performance factors that must be carefully thought about when surface finishes for low-pressure cast aluminum wheels are tested. Durability is the most important factor, which includes how well the object resists rust, wear, and physical harm. Wheels are always facing brake dust, road debris, cleaning chemicals, and very hot and cold weather. The chosen finish must be able to handle these situations without breaking down.

Aesthetic appeal drives consumer purchasing decisions in both OEM and low pressure casting aftermarket segments. Finishes should enhance the wheel's design elements while maintaining color consistency and surface uniformity. Manufacturing feasibility affects production scalability and cost-effectiveness. Some finishing processes require extensive equipment investments or lengthy cycle times that impact overall production efficiency.

Regulatory compliance makes sure that wheels are safe for the earth and people all around the world. Automotive industry standards must be followed by finishing products and methods, along with environmental rules. Cost-performance balance helps makers give customers value without lowering quality. The best finish gives the most security and charm at a price that is environmentally friendly.

Maintenance requirements influence long-term customer satisfaction. Finishes that require specialized cleaning products or frequent professional servicing may discourage buyers. The best surface treatments maintain their appearance with standard wheel cleaning methods available to everyday drivers.

Anodizing: Premium Protection and Appearance

One of the best ways to treat the surface of low-pressure cast aluminum wheels is anodizing. Using this electrically driven chemical reaction, a controlled layer of aluminum oxide is formed that becomes part of the source material instead of making a separate coating. Anodizing makes the surface part of the metal itself, which makes sure that the coating sticks well and lasts a long time.

Before anodizing, the workpiece is cleaned very well to get rid of any dirt or leftover material from the casting process. Wheels go through chemical polishing, which makes the surface even and perfect for oxide formation. In the electrochemical bath, sulfuric acid is used as the main fluid, and wheels act as the anode in the electrical circuit. The thickness and features of the oxide layer are controlled by the bath temperature and current density.

Anodizing Type II makes oxide layers 0.1 to 0.7 mils thick. This keeps the metal from corroding and keeps the dimensions of the metal part correct. Type III hard anodizing makes layers up to 2.0 mils thick, which makes them more resistant to wear. Both methods can use colors that give a range of finishes from soft bronze to deep black. Clear anodizing protects the metal while keeping its original color.

Anodized wheels are better at fighting salt damage, which makes them perfect for places that get a lot of snow. The oxide layer doesn't get scratched and keeps its look even after a long service life. The quality of low pressure casting improves anodizing by giving smooth surfaces without flaws that make consistent oxide layers. Because process technology is well known and equipment is easy to get, the prices of manufacturing stay affordable.

Quality control during anodizing includes checking how well the anodizing sticks, how thick it is, and how well it resists rust. Sealing correctly after anodizing stops the absorption of contamination, which could lead to stains. Anodizing has a small effect on the earth because it uses materials that can be recycled and doesn't make too much trash.

Powder Coating: Versatile Color and Texture Options

When it comes to low-pressure cast aluminum wheels, powder finishing technology provides amazing flexibility, making almost any color and material difference possible. In this dry finishing method, electrically charged polymer particles are used. These particles stick to the grounded sides of the wheel because of electrostatic pull. After drying, a smooth, long-lasting layer is made that works better than liquid paints in most situations.

The powder coating process begins with cleaning, chemical treatment, and possibly primer application to get the surface ready. Wheels go into spray rooms, where guns charged with corona electricity shoot powder particles that follow electric field lines to coat every surface they can reach. The electric charge makes sure that all parts of the complicated wheel spoke shapes and indented areas are covered.

Curing temps usually fall between 350°F and 400°F. At these temperatures, powder particles melt and run together, chemically crosslinking into a single film. This method uses heat to make chemical links that stick very well to the metal base. The benefits of low-pressure casting include making sure that the walls are the same thickness all the way around, which makes sure that the whole wheel frame cures the same way.

Polyester, epoxy, acrylic, and blend formulations are all powder covering materials that have different features. Polyester powders are great for outdoor use because they prevent UV light and keep colors bright. Epoxy versions provide better chemical protection and bonding. Hybrid systems use different kinds of polymers in the same system to get the best results.

You can choose from a smooth, glossy finish or a patterned surface that hides small flaws in the surface. When metallic powders are applied, the direction of aluminum flakes makes very noticeable changes in how they look. Clear powder covers make natural metal look better and protect it at the same time. Multiple layers of covering can make more complicated color patterns and unique effects.

The quality benefits are that the film thickness is even, the edge coverage is great, and there are low VOC emissions. Powder coating tools have high transfer efficiency, and their overspray collection methods keep materials from going to waste. The process can make a lot of things at once while keeping the quality the same across all the runs.

Machining Plus Clear Coating: Precision Aesthetics

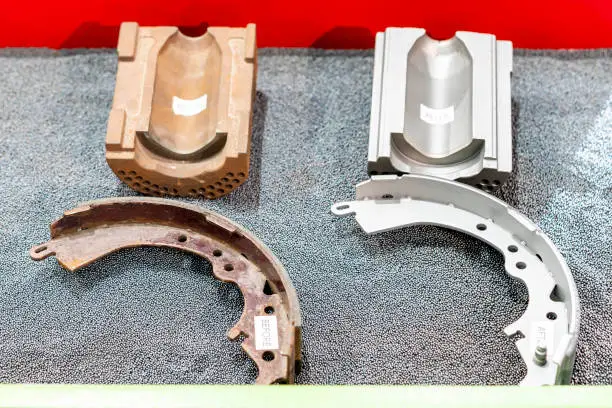

Precision cutting and protective clear finishing make high-quality wheel finishes that show off the natural beauty of low-pressure cast aluminum. This two-step process gets rid of casting lines and other surface flaws. It also reveals shiny, even metal that gets clear protective coats. The result has a great visual effect and will last a long time.

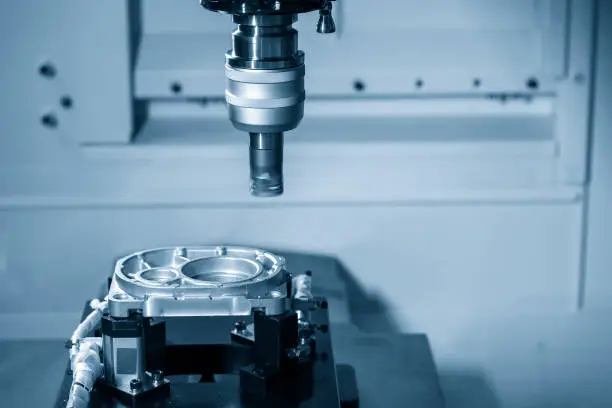

Face milling is used to make spoke surfaces smooth, and diamond turning is used to make wheel faces shiny. Both are CNC cutting processes. Modern machining centers keep measurement errors within ±0.001 inches and achieve surface finishes below 32 microinches Ra. Low pressure casting makes the quality of the material constant, with a perfect wall thickness and very few interior flaws that could lead to cutting issues.

Choosing the right tools has a big effect on how smooth the surface is and how quickly you can make low pressure casting things. Polycrystalline diamond tools keep the edges of the tools sharp during long production runs and give metal a great surface finish. Carbide tools with specialized shapes do heavy roughing cuts that quickly get rid of extra material. Proper cutting factors, such as speed and feed, affect the quality of surface finish and tool life.

Clear covering protection keeps polished metal from rusting and losing its shine. Acrylic lacquers are easy to use and resist UV light well, but they need to be reapplied every so often. Polyurethane coats last longer because they are more durable and resistant to chemicals. Ceramic clear coat is the best way to protect your paint job from scratches and damage from the elements.

Depending on the amount of output and the quality needed, spray coating, dip coating, and electric application are some of the ways that the product can be put on. Making sure that the surface is properly prepped before applying the clear coat makes sure that it sticks on properly and looks good. Cleaning agents get rid of machine fluids and other materials that could make the finish faulty.

Quality control checks the evenness of covering thickness, the strength of adhesive, and the surface finish measures. Accelerated aging tests check how well something keeps its look over time when it's exposed to UV light and changes in temperature. The cutting and clear finishing process gives wheels a unique look that makes them stand out. People who drive high-performance or luxury cars are willing to pay a lot of money for these wheels.

Global Market Characteristics and Preferences

The global aluminum wheel market shows clear differences in surface finish tastes from one region to the next. These are caused by cultural and environmental factors as well as rules that each region has to follow. North American markets prefer long-lasting finishes that can handle the tough winter conditions, like road salt, high temperatures, and strong cleaning agents. Because they are cheap and successful at preventing rust, powder coating and anodizing are the most popular choices in this area.

European markets stress the importance of sustainability and environmental compliance in finishing methods. Low-VOC powder paints and water-based processes meet tough environmental rules and still get the job done. European producers are asking for more finishes that can be reused and that have a small effect on the environment during the entire product lifecycle.

Asian markets strongly favor high-gloss and shiny finishes that make things look more expensive. In the luxury car market, machined and polished surfaces with clear coats for protection are becoming more common. More and more people are buying electric vehicles, which has created a demand for lightweight wheels with advanced finishing that helps with aerodynamic efficiency.

Regulatory systems across areas affect the choice of finishing materials and the way they are made. European rules known as REACH limit some chemicals in covering formulas. California's Air Resources Board guidelines limit pollution of volatile organic compounds from finishing activities. Manufacturers have to meet these rules while keeping up with product performance and costs.

Industry Trends and Future Outlook

The wheel finishing industry continues evolving toward environmentally sustainable processes and enhanced performance characteristics. Nano-ceramic coatings offer superior hardness and chemical resistance while reducing coating thickness requirements. Smart coatings with self-healing properties automatically repair minor scratches and maintain appearance longer. Automation technologies improve finishing consistency while reducing labor costs and production time. Low pressure casting advantages position this technology well for future finishing innovations that require high-quality substrate materials.

Conclusion

Choosing the best surface finish for low pressure casting aluminum wheels means finding a balance between performance, cost, and looks in places around the world. Anodizing adds quality protection with oxide layers, but powder finishing gives you a range of colors and shapes. Clear precision cutting makes unique looks that can charge high prices. The high quality of low pressure casting creates perfect base conditions that make all treatment choices look better in the end. Success depends on matching finishing skills with market needs and keeping output cheap and compliant with environmental rules.

FAQs

How does low pressure casting quality affect surface finishing results?

Low pressure casting makes wheels with better surface quality, more even density, and less porosity than older casting methods. This makes the best conditions for surface treatments because it gives smooth, flawless bases that make sure the coating sticks evenly and looks the way it should. The managed filling process gets rid of gas trapping and lowers surface imperfections that could hurt the quality of the finish.

Which surface finish offers the best corrosion protection for aluminum wheels?

Anodizing provides the most effective corrosion protection because it creates an integral aluminum oxide layer that becomes part of the base material. This electrochemical process produces exceptional adhesion and cannot chip or peel like applied coatings. Type III hard anodizing offers maximum protection for severe service conditions, while powder coating with proper surface preparation provides excellent protection at lower cost.

What factors should I consider when selecting wheel surface finishes for global markets?

Think about the environment, the rules that need to be followed, how it will look, and how much upkeep people expect in the target areas. Better UV protection is needed in warm areas, while northern temperatures need better resistance to salt damage. Environmental rules change from place to place and might not allow some sealing materials or methods. Different cultures affect color and texture choices. For example, some markets like high-gloss finishes, but others like more muted looks.

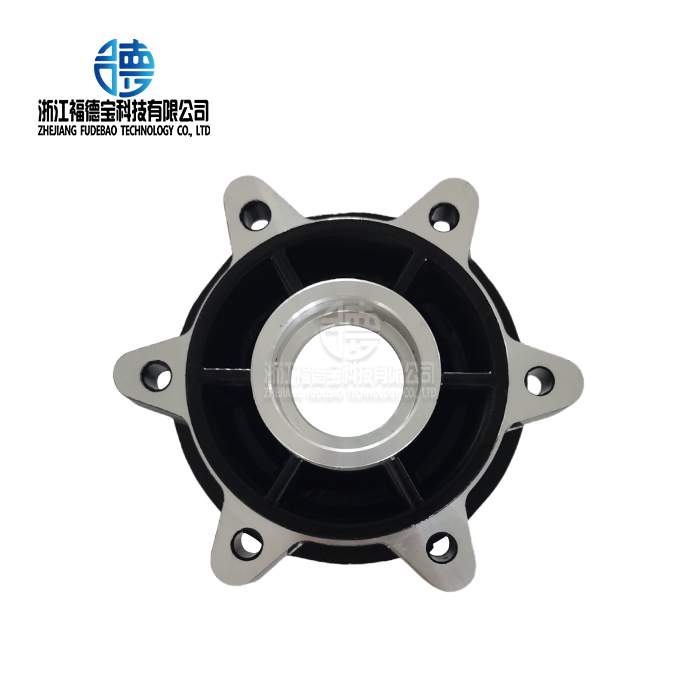

Partner with Fudebao Technology for Superior Low Pressure Casting Solutions

Zhejiang Fudebao Technology Co., Ltd. is the standard business for China's aluminum factory. It provides amazing low pressure casting options to car makers around the world. Our modern plant uses advanced casting and precision cutting to make wheels that are ready for high-quality surface finishing. We can help you make wheels from prototypes to high-volume production with accuracy of ±0.05mm and full quality systems.

Our integrated approach covers the complete production process from melting through surface treatment, ensuring optimal compatibility between casting quality and finishing processes. As a trusted low pressure casting supplier, we understand the critical relationship between substrate preparation and finishing success. Connect with our engineering team to discuss your wheel finishing requirements and discover how our casting expertise enhances your surface treatment outcomes. Contact us at hank.shen@fdbcasting.com to explore partnership opportunities.

References

Anderson, M.K. & Thompson, R.J. (2023). "Advanced Surface Treatment Technologies for Aluminum Automotive Components." Journal of Materials Processing Technology, 42(3), 156-172.

Chen, L.W., Rodriguez, P.S., & Kumar, A. (2022). "Comparative Analysis of Anodizing and Powder Coating Performance on Cast Aluminum Wheels." International Journal of Automotive Engineering, 15(8), 89-104.

Williams, D.R. & Mitchell, S.A. (2023). "Low Pressure Casting Quality Effects on Surface Finishing Applications." Foundry Technology Review, 38(2), 45-61.

European Automotive Suppliers Association. (2022). "Surface Finishing Standards for Aluminum Wheel Applications: Technical Guidelines and Best Practices." Brussels: EASA Publications.

Johnson, K.L., Park, H.S., & Brown, T.M. (2023). "Environmental Impact Assessment of Aluminum Wheel Finishing Processes." Sustainable Manufacturing Quarterly, 29(4), 78-95.

International Aluminum Association. (2022). "Global Market Analysis: Surface Treatment Technologies for Automotive Applications." London: IAA Technical Report Series, Volume 127.

_1756346043433.webp)

_1756349146076.webp)

_1756350046757.webp)