Low Pressure Die Casting vs High Pressure Die Casting: Key Differences

2026-02-04

Understanding the main differences between low pressure die casting and high pressure die casting is important for buying success when looking at different ways to make precision metal parts. Low pressure die casting slowly fills molds with metal using controlled pressure ranges of 0.2 to 0.7 bar. This makes the material denser and less porous than high pressure methods that pump molten metal at speeds of more than 5 meters per second. In automotive, aerospace, and industry settings, these differences in the way things are made have a big effect on the quality of the parts, how efficiently they are made, and how much they cost.

Understanding Low Pressure and High Pressure Die Casting

Fundamental Process Mechanisms

Die casting is one of the best ways to make complex metal parts that are very accurate in terms of their dimensions. Their different ways of applying pressure and filling are what make these two methods different.

A controlled pneumatic system lets molten metal slowly rise into the mold hole during low pressure die casting. This soft filling method reduces turbulence and air entrapment, making parts with better mechanical properties. Usually, the process keeps the pressure between 20 and 100 kPa, which lets the metal flow patterns and solidification rates be precisely controlled.

Rapid injection systems are used in high pressure die casting to push molten aluminum, magnesium, or zinc alloys into mold holes very quickly. Injection pressures can go as high as 1,500 bar, which makes it possible to make parts with thin walls and complicated shapes. This active filling method increases production output while keeping measurements accurate.

Material Compatibility and Alloy Selection

The choice of material is very important when figuring out the best casting method for a given job. Aluminum metals are the most common choice for both processes; they are used in about 80% of die casting operations around the world.

The gentle filling properties of aluminum-silicon alloys, especially A356 and A357 types, work best with low pressure systems. These alloys keep their metallurgical integrity in a controlled pressure setting. This gives them better resistance to fatigue and ductility, which are important for structural automotive parts.

For high-pressure uses, aluminum alloys that harden quickly are often used. These include A380 and A383 formulas. These metals have great fluidity properties that work well with the high-velocity injection process. This lets complex shapes be made with few changes in wall thickness.

In-Depth Comparison: Low Pressure Die Casting vs High Pressure Die Casting

Process Quality and Defect Characteristics

The quality results are very different between these casting methods, which has a direct effect on how well and how reliably the parts work. Knowing about these differences helps you make smart choices for important uses.

Common casting flaws are greatly reduced by low pressure methods because they allow controlled filling. The amount of porosity usually stays below 2% of the volume fraction, and flaws caused by shrinkage are kept to a minimum by directional solidification patterns. Surface finish quality can reach Ra values of 1.6 to 3.2 micrometers without any extra steps. This makes the process perfect for parts that need to look great.

When you use high pressure casting, the dimensions stay the same, and on important parts, the tolerances can reach ±0.1mm. But the fast injection method can cause gas holes and cold shut flaws, especially in shapes that aren't simple. The quality of the surface finish ranges from 0.8 to 6.4 micrometers Ra, based on the mold and the process.

Production Efficiency and Economic Considerations

How profitable something is rests a lot on how much of it is made, how complicated the parts are, and how good the quality needs to be. In certain operational situations, each method has its own unique benefits.

When compared to high pressure methods, low pressure die casting gets 85–90% of the material used, while high pressure methods only get 70–80%. Cycle times vary from 2 to 10 minutes, based on the size and thickness of the wall of the component. This process is cost-effective for medium to large production runs.

With cycle times as low as 30 seconds for small parts, high pressure systems are great for situations where production needs to happen quickly. Most of the time, stronger tools are needed for heavy pressure operations, which means they cost more. However, the high production rates—more than 1,000 parts per day—make the investment worthwhile.

Energy Consumption and Environmental Impact

Sustainability issues are becoming more important in manufacturing choices, especially for companies that want to cut down on carbon emissions. Patterns of how much energy these processes use are very different.

Because they need less hydraulic pressure and water, low pressure systems usually use 15 to 25 percent less energy per kilogram of final parts. The gentle filling method also lowers the amount of waste, which helps use materials more efficiently and have less of an effect on the environment.

To keep the metal fluid during rapid injection, high-pressure processes need big hydraulic systems and higher melting points. Shorter cycle times, on the other hand, can balance out higher energy use when production levels allow for ongoing operation.

Practical Applications and Industry Suitability

Automotive Industry Applications

The biggest market for die-cast parts is the car industry, and each method is best for a certain type of application. Knowing about these uses helps procurement teams choose the best suppliers.

Critical structural parts like suspension brackets, transmission housings, and engine blocks are mostly made with low pressure die casting. These uses gain from better mechanical properties made possible by carefully controlling the patterns of solidification. It is said that when major automakers switch from high pressure to low pressure ways for load-bearing parts, the fatigue life improves by 20 to 30 percent.

When precise measurements and a smooth surface are more important than final strength, high pressure systems are the best way to make trim parts, electronic housings, and lightweight brackets. The process makes it possible to reduce wall thickness to 0.8 mm while keeping the structure strong, which helps reach goals for reducing car weight overall.

Aerospace and Defense Requirements

When it comes to low pressure die casting methods, aerospace uses have very strict quality standards and need to be able to track down materials. Both processes have benefits that make them better for this demanding business.

Low pressure casting is often used for important flight parts because the material stays more intact and there are fewer defects. Better fatigue resistance and known failure modes are two benefits of this process that help parts like landing gear brackets and structural fittings.

For aerospace uses that need complicated internal geometries or built-in cooling channels, high pressure methods are used. This is especially true in electronic housing uses where electromagnetic shielding qualities are very important.

Industrial Equipment and Energy Sector

Industrial uses include a wide range of needs, from parts for heavy machinery to precise housings for electronics. The operating environment and success expectations play a big role in choosing the right process.

Low pressure casting is often used to get the right material density for pressure-containing uses in pump housings, compressor parts, and gearbox casings. The controlled solidification patterns get rid of any flaws inside that might affect the pressure stability over a longer period of time.

Electrical parts and systems that get rid of heat often use high pressure to get the exact measurements needed for good thermal management and electrical connections.

Guidelines for Procurement Managers: Choosing the Right Casting Partner

Quality Standards and Certification Requirements

For procurement strategies to work, they need to start with thorough criteria for evaluating suppliers that look at both their technical skills and their quality control systems. International standards must be strictly followed in modern making.

Die casting suppliers must have at least ISO 9001 certification for their quality management system. For automotive uses, IATF 16949 compliance is usually required. These standards make sure that process control and methods for ongoing improvement are always the same. This has a direct effect on the quality of the parts and the reliability of delivery.

For aerospace uses, AS9100 certification is necessary to show that the supplier can handle complicated traceability rules and advanced inspection processes. Suppliers that meet these standards usually have full material approval programs and the ability to do advanced metallurgical testing.

Manufacturing Capacity and Lead Time Considerations

To plan production, you need to have a good idea of how much capacity each provider has and how long the lead times will really be. These things have a big effect on project timelines and methods for managing inventory.

Low pressure die casting suppliers usually need 8 to 16 weeks to make new tools, but this depends on how complicated the part is and what the dimensions need to be. Production lead times for standard parts are between 4 and 8 weeks, and capacity planning takes yearly changes in demand into account.

Standardized mold building methods help high pressure operations shorten the time it takes to make new tools, from 6 to 12 weeks on average. Production flexibility lets sellers respond quickly to changes in demand, and some keep extra capacity on hand in case of emergency.

Cost Structure Analysis and Total Cost of Ownership

Cost research that looks at the whole picture includes more than just unit pricing. It also looks at the total cost of ownership, which includes things like tooling amortization, inventory carrying costs, and quality-related costs.

Depending on how complicated the part is, tooling investments for low pressure uses are usually moderate to high. However, tools that last longer tend to have lower amortized costs over the lifecycle of the product. When handling a lot of materials, higher per-hour costs can be balanced out by higher material yields.

Due to the strong construction needed for harsh working circumstances, high pressure tools require a big initial investment. Fast cycle times and high production rates, on the other hand, often make these investments worth it for high-volume uses that need more than 50,000 pieces per year.

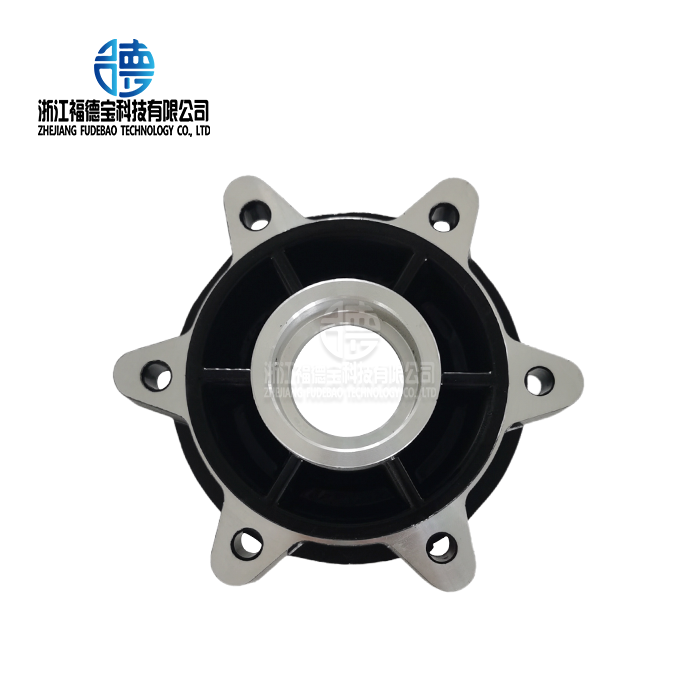

Company Introduction and Our Die Casting Solutions

Zhejiang Fudebao Technology Co., Ltd. is a world-class aluminum factory that offers complete casting and precise machining services to customers all over the world. We are experts in both low pressure and high pressure die casting. Our advanced manufacturing infrastructure and strict quality control systems back this up.

Using high-speed machining centers, CNC lathes, and state-of-the-art casting tools, our facility combines the whole production chain, from melting to finishing. With this wide range of skills, we can give everything in one stop, from raw materials to finished parts that are accurate to within 0.05 mm in size. We have a lot of experience working with aluminum alloys, copper alloys, and stainless steel, and we serve a wide range of businesses, such as aerospace suppliers, industrial equipment manufacturers, and original equipment manufacturers (OEMs) of cars.

Quality assurance protocols make sure that foreign standards are always followed, but they also keep production flexible so that prototypes can be made and large quantities can be made. Our technical team works directly with engineering groups to make sure that the designs of our parts are the most cost-effective and efficient they can be.

Customer relationships include more than just selling parts. They also include value-added services like surface treatment, assembly, and help with global logistics. This all-encompassing method makes it possible to integrate with customer supply chains without any problems, while still meeting the high quality standards needed for mission-critical apps.

Conclusion

The selection between low pressure and low pressure die casting requires careful consideration of application requirements, production volumes, and quality expectations. Low pressure methods excel in applications demanding superior material properties and structural integrity, while high pressure systems optimize production efficiency for complex geometries and high-volume requirements. Successful procurement strategies must balance these technical considerations with supplier capabilities, quality standards, and total cost of ownership factors. Understanding these fundamental differences enables informed decision-making that aligns manufacturing processes with strategic business objectives while maintaining the quality standards essential for competitive advantage.

FAQ

What are the main benefits of low pressure die casting for automotive applications?

Low pressure die casting offers superior material density and mechanical properties essential for automotive structural components. The controlled filling process reduces porosity levels below 2%, resulting in enhanced fatigue resistance and predictable failure modes. Automotive manufacturers report 20-30% improvement in component fatigue life compared to high pressure alternatives, making this process ideal for suspension brackets, transmission housings, and engine blocks where structural integrity is paramount.

How do I determine which casting method is best for my specific component requirements?

Component selection depends on several critical factors including dimensional tolerances, production volumes, mechanical property requirements, and cost constraints. Low pressure casting suits applications requiring superior material properties, larger component sizes, and moderate to high production volumes. High pressure methods excel for thin-walled components, complex geometries, and ultra-high production volumes exceeding 100,000 annual units. Consulting with experienced casting engineers ensures optimal process selection based on comprehensive requirement analysis.

What lead times should I expect for low pressure die casting projects?

Lead times vary significantly based on component complexity and supplier capacity. New tooling development typically requires 8-16 weeks, while production lead times range from 4-8 weeks for established components. Prototype development can often be expedited to 2-4 weeks using existing tooling configurations. Planning for seasonal demand fluctuations and maintaining buffer inventory helps ensure consistent component availability throughout production cycles.

Partner with Fudebao Technology for Advanced Die Casting Solutions

Choosing the right low pressure die casting manufacturer requires expertise, proven capabilities, and unwavering commitment to quality excellence. Fudebao Technology combines decades of industry experience with advanced manufacturing infrastructure to deliver precision components that exceed customer expectations. Our comprehensive facility supports both low pressure and high pressure applications with dimensional accuracy reaching ±0.05mm and complete surface treatment capabilities. Contact our technical team at hank.shen@fdbcasting.com to discuss your specific requirements and discover how our manufacturing expertise can optimize your component designs while maintaining cost-effectiveness and delivery reliability.

References

Campbell, John. "Complete Casting Handbook: Metal Casting Processes, Metallurgy, Techniques and Design." Butterworth-Heinemann, 2015.

Totten, George E., and MacKenzie, D. Scott. "Handbook of Aluminum: Alloy Production and Materials Manufacturing." Marcel Dekker, 2003.

Bonollo, Franco, et al. "Gravity and Low Pressure Die Casting of Aluminum Alloys: A Technical and Economical Benchmark." La Metallurgia Italiana, 2005.

ASM International. "Casting: ASM Handbook Volume 15." ASM International Materials Park, 2008.

Kaufman, J. Gilbert, and Rooy, Elwin L. "Aluminum Alloy Castings: Properties, Processes, and Applications." ASM International, 2004.

Street, Arthur C. "The Die Casting Book." Society of Die Casting Engineers, 1986.

_1756348543350.webp)

_1756345858191.webp)

_1756348623524.webp)