Understanding the Fundamentals of Low Pressure and High Pressure Casting

Low Pressure Casting: A Gentle Approach to Metal Forming

Low pressure casting is a process that utilizes relatively low pressure to force molten metal into a mold cavity. This method involves placing the molten metal in a sealed, pressurized furnace below the mold. As pressure increases, the metal is pushed upward through a riser tube and into the mold cavity. The gradual filling of the mold allows for controlled solidification, resulting in high-quality castings with minimal porosity and excellent mechanical properties.

One of the key advantages of low pressure casting is its ability to produce parts with thin walls and complex geometries. The controlled fill rate and reduced turbulence during the casting process contribute to improved dimensional accuracy and surface finish. This makes low pressure casting particularly suitable for automotive components, aerospace parts, and other applications requiring precise, high-quality castings.

Another benefit of low pressure casting is its efficient use of materials. The process typically has a high yield rate, meaning less waste and more cost-effective production. Additionally, the lower pressures involved in this method result in reduced wear on the molds, extending their lifespan and further contributing to cost savings.

High Pressure Casting: Speed and Efficiency in Metal Production

High pressure casting, also known as die casting, involves injecting molten metal into a mold cavity at high speed and under significant pressure. This process utilizes a steel mold (die) that can withstand the high pressures involved. The molten metal is forced into the die at pressures ranging from 10 to 175 MPa, depending on the specific casting requirements.

One of the primary advantages of high pressure casting is its ability to produce parts rapidly and in large quantities. The high injection speeds and pressures allow for quick filling of the mold cavity, resulting in shorter cycle times and increased production rates. This makes high pressure casting an excellent choice for high-volume manufacturing scenarios.

High pressure casting also excels in producing parts with thin walls and intricate details. The high pressure forces the molten metal into every nook and cranny of the mold, enabling the creation of complex shapes that would be challenging to achieve with other casting methods. Additionally, the process typically results in excellent surface finishes, reducing the need for extensive post-casting machining operations.

Comparing the Two: Strengths and Limitations

When comparing low pressure and high pressure casting, it's essential to consider the strengths and limitations of each method. Low pressure casting generally produces parts with superior mechanical properties and less porosity, making it ideal for applications requiring high strength and integrity. However, it may have longer cycle times compared to high pressure casting.

High pressure casting, on the other hand, offers faster production rates and is more suitable for high-volume manufacturing. It can produce parts with thinner walls and more intricate details than low pressure casting. However, the high pressures involved can lead to increased wear on the molds and potentially higher tooling costs.

The choice between low pressure and high pressure casting ultimately depends on factors such as part geometry, production volume, desired mechanical properties, and cost considerations. Understanding these factors is crucial for selecting the most appropriate casting method for your specific application.

Key Factors to Consider When Choosing Between Low Pressure and High Pressure Casting

Part Geometry and Complexity

The geometry and complexity of the part you intend to produce play a significant role in determining which casting method is most suitable. Low pressure casting excels in creating parts with complex shapes and thin walls, particularly when uniform wall thickness is crucial. The controlled filling process allows for the production of intricate designs with minimal defects.

High pressure casting also performs well with complex geometries but may face limitations with certain undercuts or internal features. However, it can achieve even thinner wall sections than low pressure casting, making it ideal for parts requiring extreme thinness or intricate surface details.

When evaluating your part's geometry, consider factors such as wall thickness variations, internal cavities, and overall complexity. If your design requires exceptional dimensional accuracy and uniform material properties throughout, low pressure casting might be the better choice. For parts with extremely thin walls or highly detailed surface features, high pressure casting could be more appropriate.

Production Volume and Cost Considerations

The intended production volume is a crucial factor in choosing between low pressure and high pressure casting. High pressure casting is generally more suited to high-volume production due to its faster cycle times and ability to produce parts quickly. The initial tooling costs for high pressure casting can be significant, but these costs are often offset by the higher production rates and lower per-part costs in large volume runs.

Low pressure casting, while typically slower than high pressure casting, offers advantages in terms of mold life and material efficiency. The reduced wear on molds can lead to lower long-term tooling costs, especially for medium-volume production runs. Additionally, the higher yield rates of low pressure casting can result in material cost savings.

When considering costs, it's important to look beyond just the initial investment. Factor in aspects such as mold life, material usage efficiency, cycle times, and potential post-casting operations. For smaller production runs or parts requiring frequent design changes, the lower tooling costs of low pressure casting might be more economical. For high-volume production where speed and efficiency are paramount, high pressure casting could provide better overall cost-effectiveness.

Material Properties and Quality Requirements

The desired material properties and quality requirements of your final product are critical in determining the most suitable casting method. Low pressure casting generally produces parts with superior mechanical properties, including higher strength and ductility. The controlled solidification process results in a finer grain structure and reduced porosity, which can be crucial for parts subject to high stress or requiring excellent fatigue resistance.

High pressure casting, while capable of producing high-quality parts, may sometimes result in slightly lower mechanical properties due to the rapid solidification and potential for trapped gases. However, advancements in high pressure casting technology have significantly improved the quality of parts produced by this method.

Consider the specific material properties required for your application, such as tensile strength, elongation, and impact resistance. If your part needs to meet stringent quality standards or will be used in safety-critical applications, the superior material properties achieved through low pressure casting might be necessary. For applications where slight variations in material properties are acceptable and high production speed is crucial, high pressure casting could be the more suitable option.

Optimizing Your Casting Process: Tips for Success

Design Considerations for Effective Casting

Optimizing your part design for the chosen casting method is crucial for achieving the best results. For low pressure casting, focus on maintaining uniform wall thicknesses and incorporating proper draft angles to facilitate easy removal from the mold. Consider the flow of metal during the filling process and design gating systems that promote even filling and controlled solidification.

When designing for high pressure casting, pay attention to parting line placement and minimize undercuts where possible. Incorporate adequate venting to allow trapped gases to escape, reducing the risk of porosity. Take advantage of the process's ability to produce thin walls and fine details, but be mindful of potential issues like hot spots or cold shuts that can occur in extreme geometries.

Collaborate closely with your casting supplier during the design phase. Their expertise can provide valuable insights into design modifications that can improve castability, reduce defects, and optimize overall part quality.

Material Selection and Preparation

Choosing the right alloy for your casting process is essential for achieving the desired properties and performance. Low pressure casting works well with a wide range of alloys, including aluminum, magnesium, and copper-based materials. The controlled nature of the process allows for the use of alloys that might be challenging to cast using other methods.

High pressure casting is particularly well-suited for aluminum and zinc alloys, though it can also be used with magnesium and some copper-based alloys. The high pressures and rapid solidification rates in this process can affect the microstructure and properties of the cast material, so careful alloy selection is crucial.

Proper material preparation is equally important. Ensure that the molten metal is free from impurities and gases that could lead to defects in the final casting. Implement effective degassing and filtration processes to maintain melt quality. For both low pressure and high pressure casting, maintaining precise temperature control of the molten metal is crucial for achieving consistent results.

Process Control and Quality Assurance

Implementing robust process control measures is essential for consistently producing high-quality castings. For low pressure casting, focus on maintaining precise control over the pressure ramp-up rate, hold times, and cooling rates. Monitor and adjust these parameters to optimize fill patterns and solidification behavior.

In high pressure casting, key process variables include injection speed, pressure profiles, and die temperature. Utilize advanced process monitoring systems to track these parameters in real-time and make adjustments as needed. Implement thermal management strategies to maintain consistent die temperatures, which is crucial for part quality and dimensional stability.

Develop a comprehensive quality assurance program that includes both in-process checks and final part inspections. Utilize non-destructive testing methods such as X-ray inspection or ultrasonic testing to detect internal defects. Implement statistical process control techniques to identify trends and potential issues before they lead to significant quality problems.

Conclusion

Choosing between low pressure casting and high pressure casting requires careful consideration of various factors, including part geometry, production volume, material properties, and quality requirements. Low pressure casting offers superior quality and is ideal for complex, thin-walled parts with high mechanical property demands. High pressure casting excels in high-volume production scenarios and can achieve extremely thin walls and intricate details. By understanding the strengths and limitations of each method and optimizing your design and process accordingly, you can achieve the best possible results for your specific manufacturing needs. Remember that collaboration with experienced casting professionals can provide valuable insights and help you make the most informed decision for your project.

FAQs

What are the main differences between low pressure and high pressure casting?

Low pressure casting uses lower pressures and offers better quality for complex parts, while high pressure casting uses higher pressures for faster production and thinner walls.

Which method is better for high-volume production?

High pressure casting is generally better suited for high-volume production due to its faster cycle times.

Can both methods produce parts with thin walls?

Yes, but high pressure casting can typically achieve even thinner walls than low pressure casting.

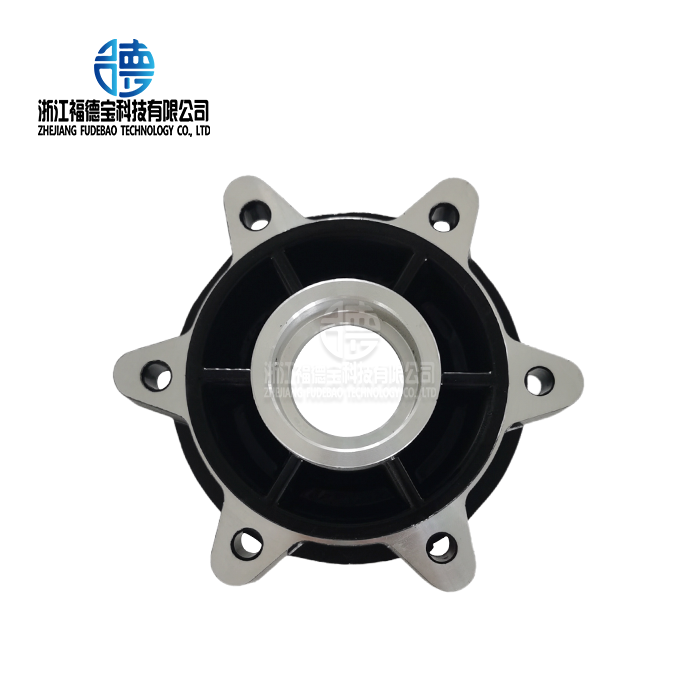

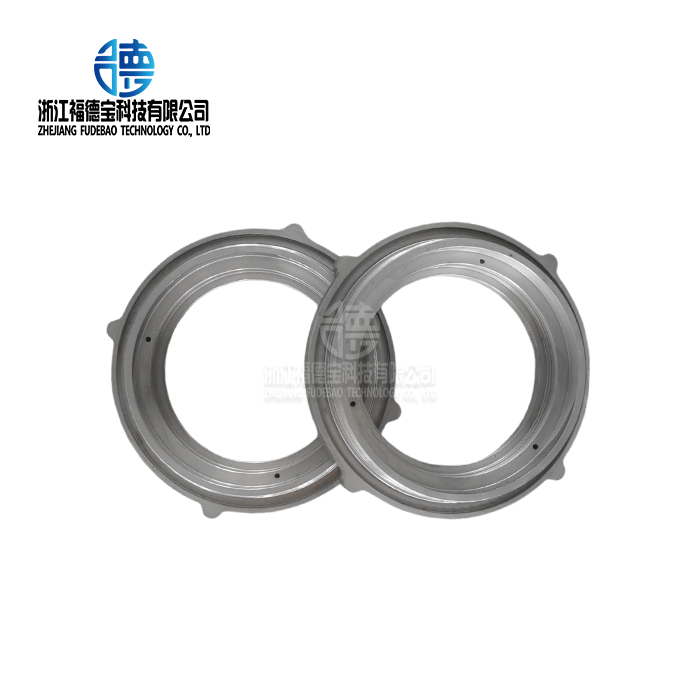

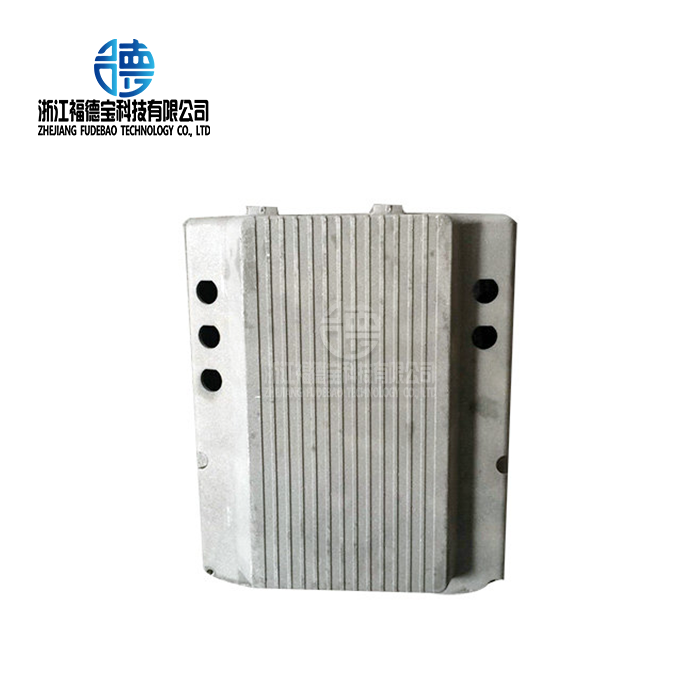

Expert Low Pressure Casting Solutions | Fudebao Technology

At Fudebao Technology, we specialize in both low pressure casting techniques, offering tailored solutions to meet your specific manufacturing needs. Our state-of-the-art facilities and experienced team ensure high-quality, precision-engineered parts for various industries. Whether you require complex automotive components or high-volume industrial parts, we have the expertise to deliver. Contact us at hank.shen@fdbcasting.com to discuss your casting project and find the optimal solution for your requirements.

References

Smith, J. (2022). Advanced Casting Technologies: A Comprehensive Guide. Metal Casting Journal, 45(3), 78-92.

Johnson, A., & Brown, T. (2021). Comparative Analysis of Low and High Pressure Die Casting Processes. International Journal of Metalcasting, 15(2), 412-428.

Lee, S., et al. (2023). Optimization of Process Parameters in Low Pressure Casting for Automotive Applications. Journal of Materials Processing Technology, 310, 117624.

Wang, X., & Zhang, Y. (2020). Recent Advances in High Pressure Die Casting Technology. Materials Today: Proceedings, 33, 1669-1675.

Garcia-Hinojosa, J., et al. (2022). Microstructure and Mechanical Properties of Low Pressure vs. High Pressure Cast Aluminum Alloys. Materials Science and Engineering: A, 832, 142395.

Thompson, R. (2021). Economic Analysis of Casting Processes: Low Pressure vs. High Pressure Methods. Journal of Manufacturing Systems, 58, 176-185.

_1756348356531.webp)

_1756361494985.webp)